cleaning and preventive maintenance of insectocutor (insect-o-cutor)

1.0 OBJECTIVE

1.1 To describe a procedure for cleaning and preventive maintenance of Insect-o-cutor.

2.0 SCOPE

2.1 This procedure is applicable to all Insect-o-cutor

3.0 RESPONSIBILITY

3.1 The Maintenance staff performs the cleaning and maintenance procedure of Insectocutor as per this SOP.

3.2 The Maintenance Officer/Executive shall execute this SOP.

3.3 Head of Maintenance department shall ensure the compliance of this SOP.

4.0 ACCOUNTABILITY

4.1 Head Engineering

4.2 Head QA

5.0 PROCEDURE

5.1 Check the input voltage to the transformer.

5.2 Check the all electrical connection. If any loose connection tight the all loose connection.

5.3 Do the cleaning as per the SOP No

5.4 Check the Fluoresces light and check the Insect-o-cutor coil is properly working.

5.5 Check the tightness of the grill and frames of Insect-o-cutor.

5.6 Frequency : Once in every month

5.7 Maintenance department shall maintain the maintenance records of Insectocutor as per Format No

6.0 TRAINING

6.1 Trainer – Head-QA.

6.2 Trainee – All Concern Person.

6.3 Period – One hour or as per required.

7.0 DISTRIBUTION

7.1 One set of master copy & controlled copy submitted the quality assurance department.

8.0 ENCLOSURE

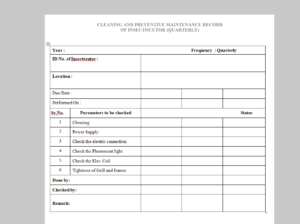

8.1 : Cleaning and Preventive Maintenance Record of Insectocutor.

9.0 ABBREVIATIONS

9.1 SOP : Standard Operating Procedure

9.2 MND : Maintenance Department

9.3 QA : Quality Assurance

cleaning and preventive maintenance of insectocutor (insect-o-cutor)