sop for control of process deviation

1.0. OBJECTIVE:

The objective of this SOP is:

1.1 To describe a procedure for handling of process deviations.

2.0. RESPONSIBILITY:

2.1 Head of the Concerned Department shall be:

2.1.1. Responsible for initiation as well as investigation on process deviation.

2.2 Quality Assurance shall be:

2.2.1 Responsible for investigating and approving the process deviation report.

3.0. ACCOUNTABILITY:

Head – Quality Assurance

4.0. PROCEDURE:

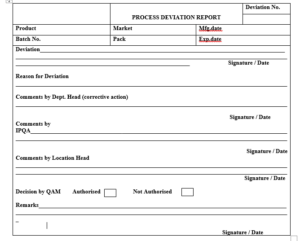

4.1 No process deviation shall be permitted under operating conditions however, in case the deviation has occurred or it is unavoidable, the same shall be immediately brought to the notice of Quality Assurance. The process deviation report shall be filled in duplicate as per Annexure –1.

4.2 The stage of operation and nature of deviation shall be recorded in process deviation report along with the reason for deviation.

4.3 The Dept. Head shall investigate into the deviation and put his comments on process deviation report, which shall include the steps to avoid such deviations in future. The report shall then be forwarded to IPQA for comments and recommendations.

4.4 The IPQA shall review the deviation in line with regulatory / GMP compliance.

4.5 The impact of process deviation on product identity, strength, quality and purity shall be reviewed by IPQA.

4.6 Based on above review, IPQA shall give their recommendation, which may include steps to avoid such deviation in future and additional testing on the product involved if required.

4.7 The report shall then be forwarded to Head – Plant Operations for comments and recommendations.

4.8 Based on the results of experiments carried out during process Validation or any past incidences of similar nature may be used for taking decision on the product.

4.9 The final decision on the involved product shall be taken by Head – Quality Assurance

4.10 After the deviation has been authorised by QA Head, original copy of deviation shall be filed in QA department. Two photocopies shall be taken, one filed with the Batch Production Record and other with remain with the concern department. If the deviation is not authorised by QA, then also the copies will original copy of the deviation report shall be filed in Batch Production Record and the batch shall be rejected.

4.11 In case of a deviation with respect to some material, which may affect more than one production batch the batch Production Record of the first batch will have the original copy and the photocopies shall be filed in the Batch Production Records of other affected batches.

4.12 Each process deviation report shall be numbered by a Quality Assurance Department in the following manner.

4.13 The number shall comprise of 4 characters.

4.14 The first character shall be an alphabet representing the originating Department as listed below:-

1. Production Area Oral Dosage — “A”

2. Production Area Injectables — “B” — “

3. Warehouse — “C”

4. Quality assurance — “D”

4.15 The next 3 characters shall be a 3 digits serial number starting ‘001’ for each Calender year.

4.16 Quality Assurance Department shall maintain a log of deviations done which should include

Following information,

1. Serial number

2. Product / Batch no. if any

3. Nature of deviation

4. Corrective action taken or planned.

4.17 Trend analysis of all deviation shall be performed annually and shall form part of annual product review.

5.0. REASON FOR REVISION:

This SOP is revised due to revision due date.

6.0. TRAINING:

Trainer — Head – Quality Assurance

Trainee — All departmental heads / Quality Assurance Personnel

Period — One day

7.0. DISTRIBUTION:

Certified Copy No. 1 : Head of Department – Quality Control

Certified Copy No. 4 : Head of Department – Warehouse

Certified Copy No. 5 : Head – Plant head

Original Copy : Head – QUALITY ASSURANCE

8.0. ANNEXURE:

Annexure – 1 : Format for Process Deviation Report

9.0. REFERENCE:

In-House

ANNEXURE – 1

FORMAT FOR PROCESS DEVIATION REPORT