sop for equipment log card

1.0 OBJECTIVE

1.1 The objective of this SOP is to define the procedure for recording the operation cleaning and maintenance related machine utilization details of all the individual equipment.

2.0 SCOPE

2.1 This SOP is applicable for operation, cleaning and maintenance related machine utilization details of all the individual equipment used production department

3.0 RESPONSIBILITY

3.1 Asst. Officer or above –Concerned Department

4.0 ACCOUNTABILITY

4.1 Head – Concerned Department / Chief Executive Officer

5.0 REFERENCE(S)

5.1 In-House

6.0 PROCEDURE:

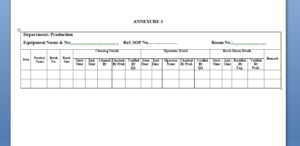

Each and every equipment consumption related with it’s operation, cleaning and maintenance will be recorded in “Equipment Log Card” separately for all the individual machine as per below mentioned instruction as per Format Write the Name of Department and Section at specified place in the format.

6.1 Write the Name of Equipment, relevant Equipment ID No. as well as it’s location.

6.2 Write the Date on which a particular activity is performed.

6.3 Write the Product name for processing of which the machine has been utilized.

6.4 Write the time duration taken for completion of a particular activity e.g. Cleaning, Operation or breakdown for maintenance.

6.5 After completion of operation or cleaning activity production personnel as well as QA personnel monitoring the same will put his signature at specified column in the equipment log card.

6.6 After completion of maintenance activity engineering personnel as well as production personnel monitoring the same will put his signature at specified column in the equipment log card.

6.7 Specific observation observed during any activity will be recorded in the Remark column, In case of lack of space the same will be recorded in the back side of the format but writing P.T.O. in remark column with signature.

6.8 Any equipment related with processing or dispensing shall be cleaned and its CIP /SIP/ wash water analysis release from QA will be taken prior to it’s startup for processing activity.

6.9 If any cleaned / sanitized/ sterilized (Injectable) machine not operated within 24 hours (for Injection) will be re-subjected for it’s cleaning / sterilization (if applicable) as well as it’s CIP /SIP /Wash water analysis release from QA will be taken prior to it’s startup for processing activity .

6.10 In Case of maintenance work done on a particular machine the machine will be cleaned & sanitized and it’s release will be taken by QA prior to startup of it’s startup for Processing activity.

6.11 In Case of continuous operation for different batch of a similar product or only one batch of Large Batch size, machine will not be operated continuously for more than 72 hours (for Injection) and after completion of this period remaining bulk solution / materials will be re-filter (if applicable) and machine will be cleaned / sterilized / sanitized and it’s CIP /SIP/ wash water analysis release from QA will be taken prior to it’s startup for processing activity.

6.12 In Case of product change over machine will be cleaned and sterilized / sanitized and it’s CIP /SIP / wash water analysis release from QA will be taken prior to it’s startup for processing activity.

7.0 ABBREVIATIONS

QA : Quality Assurance

CIP : Cleaning in Place

SIP : Sterilization in Place

8.0 ANNEXURE

| Annexure No. | Title of Annexure |

| Annexure-I | Equipment Log Card |

ANNEXURE-I