sop for handling of returned goods

1.0 OBJECTIVE

1.1 The objective of this SOP is to define the procedure for handling of returned goods.

2.0 SCOPE

2.1 This SOP is applicable for handling of returned goods

3.0 RESPONSIBILITY

3.1 Officer –Quality assurance-Prepare the SOP and follow-up the SOP accordingly

3.2 Asst. manager –Quality assurance -Provide the support to the implementation of SOP and maintained the records.

4.0 ACCOUNTABILITY

4.1 Head – Quality Assurance / Chief Executive Officer

5.0 REFERENCE(S)

5.1 In-House

6.0 PROCEDURE:

6.1 After receiving the returned Goods Officer / Executive store will record the details as well as identification of returned finished goods and keep in area specified for Returned Goods Storage Area to avoid mix-up with trade.

6.2 Finished Goods Incharge will intimate QA as well as CEO.

6.3 QA person shall check physically the returned good and prepare the investigation report for return goods as mentioned in Format

6.4 QA head shall take the decision with consultation of Head Production, Head QC and CEO.

6.5 If returned products is found rectifiable, it will be discussed with Head production and further corrective action will be taken.

6.6 If returned goods found not rectifiable the material to be destroyed as per SOP and after approval of CEO.

6.7 After getting approval for destruction all the returned goods shippers will be taken out from return goods storage area to place specified for Material Awaiting for Destruction followed by crossing the outer status label with marker pen.

6.8 The unit Carton, PP bags, Leaflets etc. are torn into pieces.

6.9 The dust caps are removed, Materials inside the LDPE bottle are removed from it then all labeled bottles are crossed and taken along with the shipper near the cutter machine/scrap area.

6.10 The empty Shippers, Unit Cartons, Leaflets, Poly Bag, etc. will be destroyed by shredding into pieces followed by burning.

6.11 Disposition of returned goods to be recorded in format as mentioned in Format.

6.12 Attached the photocopy of destruction note with investigation report for returned goods.

6.13 Head QA shall approve and close the investigation report for return goods and send to CEO for final authorization and signing.

6.14 After signed by CEO, QA person shall attach the investigation report for returned goods with destruction note in the concerned BMR/BPR.

7.0 ABBREVIATIONS

SOP : Standard Operating Procedure

QA : Quality Assurance

BMR : Batch Manufacturing Record

BPR : Batch Packing Record

CEO : Chief Executive Officer

8.0 ANNEXURE

| Annexure No. | Title of Annexure |

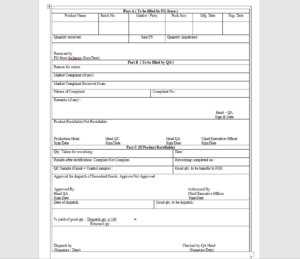

| Annexure-I | Investigation Report For Return Goods |

Annexure-I

Investigation Report For Return Goods