sop for monitoring of temperature and humidity

1.0 OBJECTIVE

1.1 The objective of this SOP is to define the procedure for monitoring of temperature & humidity of different area where monitoring of temperature & humidity is required.

2.0 SCOPE

2.1 This SOP is applicable for monitoring of temperature & humidity of different area of production and other required area

3.0 RESPONSIBILITY

3.1 Officer / Executive – Concerned Department/Quality Assurance

4.0 ACCOUNTABILITY

4.1 Head – Concerned Department / Quality Assurance/ Chief Executive Officer

5.0 REFERENCE(S)

5.1 In-House

6.0 PROCEDURE:

6.1 Monitoring of Temperature and Humidity (By Wet and Dry Hygrometer)

6.1.1 Ensure that hygrometer (Wet & Dry Hygrometer) is calibrated.

6.1.2 Take reading of dry bulb thermometer and wet bulb thermometer for calculating % relative humidity of area and note in logbook or record direct reading from electronic digital hygrometer.

6.1.3 Ensure the hygrometer is cleaned.

6.1.4 Ensure that sufficient water available in the reservoir of hygrometer and thread is wet of wet thermometer.

6.1.5 Record the temperature from dry bulb thermometer (a).

6.1.6 Record the temperature of wet bulb thermometer (b).

6.1.7 Calculate the relative humidity (RH) as:

6.1.7.1 Calculate the difference in temperature as (a-b)

6.1.7.2 Read RH from relative humidity chart for temperature of dry bulb on the difference value i.e. (a-b).

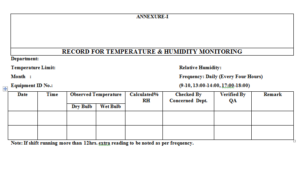

6.1.8 Record the observed temperature & humidity in Record for Temperature and Humidity Monitoring as per Format No.

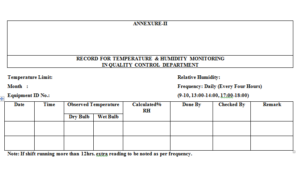

6.1.9 Quality Control dept. shall record the observed temperature & humidity in Record for Temperature and Humidity Monitoring as per Format No.

6.2 Monitoring of Temperature and Humidity (By Digital Hygrometer)

6.2.1 Digital hygrometer shall be used where applicable.

6.2.2 Ensure that digital hygrometer is calibrated.

6.2.3 Ensure the hygrometer is cleaned.

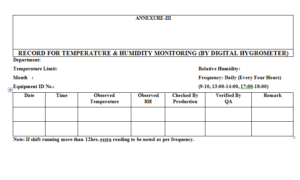

6.2.4 Record the observed temperature & humidity in Record for Temperature and Humidity Monitoring (for Digital Hygrometer) as per Format No.

6.3 Monitoring of Minimum and Maximum Temperature:

6.3.1 Minimum and maximum temperature to be recorded for the warehouses of RM/PM/FG/ where only temperature is monitoring.

6.3.2 Ensure that the Minimum and maximum thermometer is cleaned.

6.3.3 Use calibrated Minimum and maximum thermometers for recording of minimum and maximum temperature.

6.3.4 The instrument must be placed in vertical position with mercury bulb at the bottom.

6.3.5 Read the temperature from thermometer in the respective areas and note the same in respective record.

6.3.6 Minimum and maximum thermometer must be fixed at point as per temperature mapping report.

6.3.7 Temperature shall be recorded from morning to evening every 4 hours interval. (i.e. 9:00 to 10:00 AM, 13:00 to 14:00 and 17:00 to 18:00).

6.3.8 Every day morning around 10:00 AM record the minimum and maximum temperature from minimum & maximum thermometer for 24 hrs. and reset the thermometer indicators of minimum and maximum thermometer.

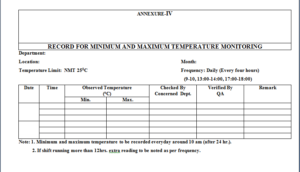

6.3.9 Minimum and maximum temperature to be noted in Record for Minimum and Maximum Temperature Monitoring as per Format No.

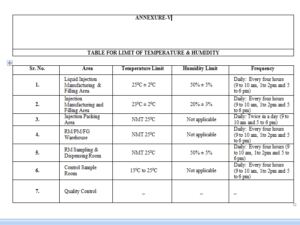

6.4 Limit and frequency for monitoring of temperature & humidity (where applicable) for different areas mentioned in Table for Limit of Temperature & Humidity as per Format No.

6.5 In case of non compliance of observed temperature intimate maintenance department for corrective action and production & QA to stop the production activity until observed temperature is within limit.

6.6 If any reading crosses the limit (during process or during monitoring), Stop process and inform immediately to Engineering departments for rectification and Q.A. department for information through ‘Maintenance Report’ duly filled & signed by concerned department.

6.7 Engineering department shall rectify problem and inform to concerned department and QA department for monitoring of temperature and humidity.

6.8 Quality assurance department shall take a decision on further processing of relevant batch, with information available from production / engineering and quality control department. If needed, additional sampling / testing or stability to be done.

7.0 ABBREVIATIONS

SOP : Standard Operating Procedure

QA : Quality Assurance

FG : Finished Goods

8.0 ANNEXURE

| Annexure No. | Title of Annexure |

| Annexure-I | Record for Temperature & Humidity Monitoring |

| Annexure-II | Record for Temperature & Humidity Monitoring in Quality Control Department |

| Annexure-III | Record for Temperature & Humidity Monitoring

(For Digital Hygrometer) |

| Annexure-IV | Record for Minimum and Maximum Temperature Monitoring |

| Annexure-V | Table for limit of Temperature & Humidity |