sop for of environmental conditions of control sample room

1.0. PURPOSE:

To lay down the procedure for daily monitoring of environmental conditions i.e. Temperature and Relative Humidity in Control Sample Room

2.0. RESPONSIBILITY:

4.1 The Officer Quality Assurance shall be:

4.1.1 Responsible for daily monitoring the environmental conditions

4.1.2 Responsible for recording the environmental conditions in the environmental monitoring Record

4.2 The Executive Quality Assurance shall be:

4.2.1 Responsible for ensuring the daily monitoring the environmental conditions.

4.2.2 Responsible for ensuring the environmental conditions are in the specified limit.

3.0. ACCOUNTABILITY:

Departmental Head – Quality Assurance

4.0. PROCEDURE:

4.3 Humidity & Temperature Recording

4.3.1 Use calibrated Hygrometer for recording of Relative Humidity and Temperature by the following procedure.

4.3.2 Check the water level and fill the water compartment with water by using wash bottle.

4.3.3 Ensure that the wick is clean and soaked in water to ensure constant flow of water to the wet bulb.

4.3.4 Remove the hygrometer from the wall and swing it at about 45° angle about 100 rotations and check the readings

till constant readings are attained. Take care while swinging the Hygrometer to avoid spillage of water from the water compartment.

4.3.5 Note down the temperature readings of dry and wet bulbs in degree Celsius.

4.3.6 Subtract wet bulb temperature reading from the dry bulb temperature reading to get the depression in temperature of wet bulb in degree Celsius.

4.3.7 Record the percent relative humidity from the RH table corresponding to dry bulb temperature along the left side of

the table and depression of wet bulb temperature along the top of the table.

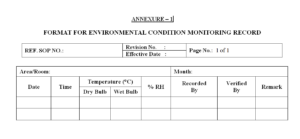

4.3.8 Record dry bulb temperature; wet bulb temperature and relative humidity twice in a day on

the ‘Environmental Monitoring Record’ (Annexure – 1) of predetermined areas.

4.3.9 If there are any abnormal observations, in the readings of temperature, head of

the Department shall be intimated for necessary actions in coordination with Head – Engineering.

5.0. REASON FOR REVISION:

This procedure is modified in order to more effective in monitoring; responsibility and incorporation of modified Environmental Condition Record.

6.0. TRAINING:

Trainer — Head – Quality Control

Trainee — Quality Control Executives and Officers

7.0. DISTRIBUTION:

Certified Copy No. 1 : Head of Department – Quality Control

Reference Copy No. 2 : For Display in Control Sample Room

Original Copy : Head – QUALITY ASSURANCE

8.0. ANNEXURE:

Annexure – 1 : Format for Environmental Condition Monitoring Record

9.0. REFERENCE:

In-house.