sop for Operation Of Effluent Treatment Plant

1.0 Objective :

To lay down a procedure for the operation of Pressure Sand Filter, Activated Carbon Filter and Effluent Treatment Plant.

2.0 Scope

This Standard Operating Procedure is applicable for Operation of Effluent Treatment Plant to be followed at formulation plants

3.0 Responsibility

3.1 Engineering Officer / Executive shall be responsible for the execution of this procedure.

3.2 Engineering Manager shall be responsible for the implementation of this SOP.

3.3 Head QA/designee shall be responsible for the compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure etc

No : Number

QA : Quality Assurance

NA : Not Applicable

Sr. No : Serial number

Hrs : Hours

PSF : Press Sand Filter

ACF : Activated Carbon Filter

MLSS : Mixed Liquor Suspended Solids

ER : Engineering

5.0 Procedure

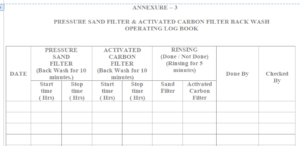

5.1 Pressure sand filter (PSF)back wash procedure:

5.1.1 Ensure the PSF feed pump to be closed before operating the valve of Sand Filter.

5.1.2 Back wash position for 10 minutes.

5.1.3 Rinse for 5 Minutes.

5.1.4 Initial Mode (Filter Mode).

5.2 Activated Carbon Filter (ACF) Back Wash Procedure:

5.2.1 Ensure the ACF feed pump to be closed before operating the valve of Sand Filter.

5.2.2 Back wash position for 10 minutes.

5.2.3 Rinse for 5 Minutes.

5.2.4 Initial Mode (Filter Mode).

5.3 Procedure for the operation of effluent treatment plant (ETP).

5.3.1 Switch on the panel.

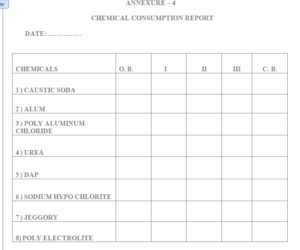

5.3.2 Process effluent from the manufacturing process receives to the collection tank and transfer to the Equalization Tank through the Oil & Grease tank. Add Caustic (300 – 400) mg/l to the equalization tank to raise the pH up to 8 – 9.5.

5.3.3 Switch on the Effluent transfer Pump and allow the effluent from Equalization tank continuously to Flax Mixer. The domestic waste received in the septic collection tank, is then transfer to the Aeration tank as well as the SAFF reactor.

5.3.4 Add ALUM (Aluminum Sulphate) (600 – 800) mg/l respectively to adjust the pH to 7-8 and PAC (Poly Aluminum Chloride) (10 mg/l) to remove the colour in the Flux Mixer.

5.3.5 Allow effluent after adjusting pH will be sent to Primary Clarifier by gravity. The solids will be settled down at the bottom through the tubular type clarifier. Allow clean water (supernatant) will be sent to Aeration Tank by gravity.

5.3.6 Add urea approx. 500gms and Di–Ammonium Phosphate (DAP) approx. 200gms to the Aeration tank as well as SAFF Reactor daily, which acts as nutrients for the bacteria and beneficial for the bacterial growth.

5.3.7 Switch on the Air Blower for supplying the diffused air from bottom. Maintain the MLSS (Mixed Liquor Suspended Solids) in Aeration tank / SAFF reactor. Switch on the Sludge Recycle Pump to maintain the MLSS in between the required range up to 3000-3500 mg/l. ( if required ), in the aeration tank as well as in SAFF Reactor.

5.3.8 Allow supernatant water from secondary clarifier will be sent to the Feed Sump by gravity. Transfer the loads from the Feed Sump to the Pressure Sand Filter (PSF) and then to the Activated Carbon Filter (ACF).

5.3.9 Send the drains from both the clarifiers to Sludge Drying Beds.

5.3.10 Send the filtrate from the sludge drying beds progress to the equalization tank. The dried sludge is used as manure in the garden.

5.3.11 From the ACF filtered water will be collected in the Final Treated Holding tank.

5.3.12 Add dosing of Sodium Hypo Chlorite (1 % sol v/v) in the Final Treated Holding for chlorination.

5.3.13 Allow the chlorinated water from the Final Treated Holding tank will be used for irrigation purpose in the green belt.

5.3.14 The treated water should be meet the following limits.

6.0 Forms and Records

6.1 Effluent Treatment Plant operation Log Book – Annexure-1

6.2 Specification of Effluent Treated Water – Annexure-2

6.3 PSF & ACF Back Wash Operating Log Book – Annexure-3

6.4 ETP Analysis Report – Annexure-4

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Engineering Department