sop for out of calibration

1.0 OBJECTIVE

1.1 The objective of this SOP is to define the procedure for handling of out of calibration instruments.

2.0 SCOPE

2.1 This SOP is applicable for handling of out of calibration instruments

3.0 RESPONSIBILITY

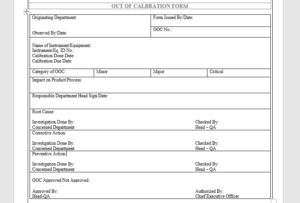

3.1 Officer –Quality assurance-Prepare the SOP and follow-up the SOP accordingly

3.2 Asst. manager –Quality assurance / Manager -Quality control- Provide the support to the implementation of SOP and maintained the records.

4.0 ACCOUNTABILITY

4.1 Head – Quality Assurance

5.0 REFERENCE(S)

5.1 In-House

6.0 PROCEDURE

6.1 Instrument that is used as standard calibration instrument should be under calibration validity period.

6.2 Calibration standards should be traceable to national standards with authentic calibration certificate.

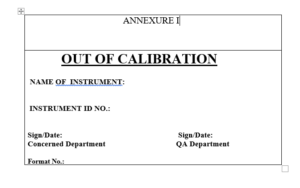

6.3 Whenever equipment is found to be OOC, immediately withhold its use in any process and put the label ‘Out of Calibration’ on that instrument as per Format No.

6.4 No efforts should be made to rectify instrument error, immediate report to Head-QA.

6.5 Check the calibration period of the equipment.

6.6 QA department shall issue the OOC form as per Format No. with OOC No.

6.7 OOC No. shall be as OOC/YYY/MM/ZZ/NNN

Where:

OOC : Out of Calibration

YYY : Department Code

MM : Month

ZZ : Year Code

NNN : Serial No.

6.8 Concerned Department shall fill the OOC Form and submit to QA department.

6.9 Head-QA will identify the OOC defects as critical, major or minor on the basis of assessment of possible impact of such defect on the product.

6.10 Defects are categorized as follows :

6.10.1 Critical – A functional defect that is certain to cause failure of the product to fulfill its intended purpose.

6.10.2 Major – Defects that may cause failure of the product to fulfill its intended purpose.

6.10.3 Minor – Defect that may not prevent the product from fulfilling its intended purpose.

6.11 On the basis of possible impact on the product quality, Head-QA will define it as critical, major or minor.

6.12 The Head-QA and the concerned department head will prepare a joint investigation report.

6.13 In the same report the concerned department Head along with Head-QA will list the corrective action to be taken.

6.14 If corrective action report recommends for reanalysis, the QC Head will decide the quantity to be reanalyzed and nature of reanalysis.

6.15 The findings & conclusion of reanalysis will be attached with OOC form and forwarded to Head-QA for further action.

6.16 Engineering manager will decide whether the OOC equipment can be rectified in house or needs to be sent outside for repairs or needs replacement in part or whole.

6.17 Irrespective of the way of repairs, the equipment will be recalibrated and authorized by Head-QA before it is reinstalled for use.

6.18 Preventive action to be taken by concerned department to avoid the reoccurrence in future.

6.19 After found satisfactory, Head QA shall approve the OOC form and send to Chief Executive Office for final authorization.

7.0 ABBREVIATIONS

SOP : Standard Operating Procedure

QA : Quality Assurance

OOC : Out of Calibration

QC : Quality Control

8.0 ANNEXURE

| Annexure No. | Title of Annexure |

| Annexure-I | Out of Calibration |

| Annexure-II | Out of Calibration Form |

Annexure-I

Out of Calibration

Annexure-II

Out of Calibration Form