sop for standard batch size

1.0 OBJECTIVE

1.1 The objective of this SOP is to standardize the batch size of products.

2.0 SCOPE

2.1 This SOP is applicable for standardizing the batch size of Injectable products manufacturing

3.0 RESPONSIBILITY

3.1 Asst. Officer or above –Quality assurance – Prepare the SOP and follow-up the SOP accordingly

3.2 Asst. manager –Quality assurance -Provide the support to the implementation of SOP and maintained the records.

4.0 ACCOUNTABILITY

4.1 Head – Quality Assurance Department / Chief Executive Officer

5.0 REFERENCE(S)

5.1 In House.

6.0 PROCEDURE

6.1 All the products to be manufactured with standard batch size.

6.2 Batch size shall be finalized and standardized on the basis of process validation results.

6.3 In case of batch not planned for manufacturing as per standard batch size a planned deviation shall be raised with comments as per approved deviation procedure as per SOP

6.4 After approval of deviation form by QA and authorized by Chief Executive Officer, batch shall be taken with extra precaution and sampling & analysis shall be done as per validation schedule.

6.5 A controlled copy of approved deviation form shall be attached with BMR/BPR.

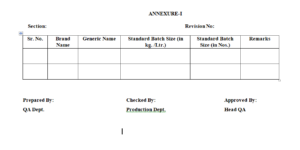

6.6 A list of products with standard batch size shall be prepared by QA personnel as per Format

7.0 ABBREVIATIONS

SOP : Standard Operating Procedure

QA : Quality Assurance

BPR : Batch Processing Record

BMR : Batch Manufacturing Record

8.0 ANNEXURE

| Annexure No. | Title of Annexure |

| Annexure-I | List of Product With Standard Batch Size |