standard operating procedure handling of flexible pipes

PURPOSE

To define a procedure for receipt, certification, coding, cleaning, storage, usage and disposal of flexible pipes.

This procedure applies to flexible pipes For example, Silicon hose, nylon, SS braided teflon, SS braided silicon, silicon rubber,

PVC compound flexible hose which are coming in the product contact or pipes used for transfer of solution/suspension which are coming in product contact.

Quality Assurance:

Verification of the pipes against the required specification, approval for disposal of pipes.

.

Quality Assurance Head:

To ensure implementation of the defined procedure.

Plant Head:

To ensure implementation of the defined procedure.

Distribution:

I. Quality Assurance

II. Quality Control

III. Production

IV. Ware house

PROCEDURE:

As per requirement, the user department shall raise an indent stating the details like MOC/composition

dimension (inner diameter, outer diameter and length), wall thickness, supplier name, colour etc.

Flexible pipes shall be purchased from approved suppliers only.

Receipt, Certification, Cleaning, Coding and Storage of flexible pipe:

On receipt of new flexible pipe user department shall check as per Attachment-I.

Note:

1. Cracks on the inner surface of pipe shall be checked by cutting and opening the small piece of pipe from mother piece (wherever applicable).

2. The dimension of the pipe shall be checked using Vernier Calliper and measuring tape.

The MOC/composition of the tubing written on manufacturer certificate shall be verified against indent.

The flexible pipe received shall comply with the required specification and same shall be verified by Quality Assurance.

If the quality of flexible pipe is not found satisfactory then send it to the manufacturer/supplier as rejected item.

If the parameters of flexible pipe are within acceptance criteria, clean the pipe as per following procedure.

Cleaning of pipes shall be done in washing area.

The flexible pipes shall be cleaned from inside and outside with potable water and detergent solution and finally rinse with purified water.

Drain the water from the flexible pipe by hanging it in inverted ‘∩’ position i.e. ‘∩’ (if possible) in the pipe stands which is available in the wash area.

Flush the flexible pipe with filtered compressed air until dry.

Close the open ends of the hose pipe using fresh aluminium foil or bacterial barrier paper.

Affix the ‘Cleaned’ label as per SOP.

After cleaning, coding of the pipes shall be done as follows:

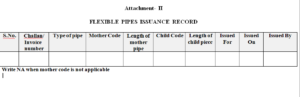

If pipe has to be cut in to the pieces then mother code number shall be allocated to main pipe as follows and for individual piece, allocate a child number. The code number shall be written at the end of the pipe.

Note: Product abbreviation or equipment abbreviation shall be recorded in Attachment-II in column ‘Issued for’.

M: Abbreviation for process application like Sifting, Blending, filtration, filling, purging, for transferring product from manufacturing to filling hopper/mixing vessel (When it is not applicable, then it can be omitted during coding).

For example,

S : For Sifting

B : For Blending F : For Filling

T : For Transferring

NN : is for Colour code For example,

WH : White BK : Black

BL : Blue

YY : Year (16 for 2016, 17 for 2017)

It shall be effective Year when a flexible pipe, is started for use.

DD : Month (01 for Jan, 02 for February, 03 for March……)

It shall be effective month when a flexible pipe shall be started to use.

XX : Serial number (01, 02, 03 )

It shall be for the entire set of flexible pipe, for a particular product or particular process application started use from a particular month and year.

For example, the flexible pipe started use from December 2016 in Production department for ……….

product for sifting shall be numbered as PRD/PRS/SIF/16/12/01.

Whenever, flexible pipe is not cut in to pieces and used directly, it has to be numbered directly as child piece.

Whenever code is allocated it shall to be recorded in Attachment-II.

After coding, store it in appropriate place by rolling it into a coil and put into fresh polythene bag and seal the bag with fastener.

USAGES:

Few examples of pipes used for different purpose are as follows.

PVC concealed SS wire braided flexible pipe: For product transfer.

Silicon flexible pipe: For binder spraying, coating suspension, etc.

SS Braided Silicon flexible pipe: For coating suspension transfer.

Festo pipe: For suspension transfer from feeder to gun.

Dedicated flexible pipes shall be used for each product transfer, wherever required.

Flexible pipes shall be checked visually for defects like cracks, holes, and outer smoothness prior and after use and same shall be recorded in Attachment-III.

After usage, clean the pipe as per respective SOP.

Precaution for handling of flexible pipes:

Do not keep ends of flexible pipes open. If it is not connected, closed the end with cleaned aluminium foil or bacterial barrier paper or with dead end. Affix cleaned label and store in the cleaned area.

While connecting the flexible pipe, ensure that tightening does not result in twisting of flexible pipe as twisting may lead to damage to the pipe.

Disposal:

When pipes become hard, looses it elasticity, flexibility, integrity, physical abrasion, when pipe is leaking, change in colour is observed, pipes shall be immediately disposed.

Dispose the SS Braided tubing/PVC concealed SS wire braided flexible pipe after 5 years and other pipes shall be disposed after every 1 year from the date of issue or as and when required.

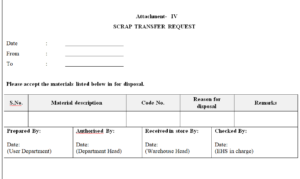

SS braided pipe shall be destroyed by deforming using hammer and other pipes shall be disposed of by cutting into the different length.

If any pipe is not used for a period of 5 years, then it has to be disposed.

Keep the pipes and tubes which are to be destroyed in polythene bag with duly labelled with sign and date.

Transfer pipe to be disposed to scrap yard and record in Attachment-IV and Attachment-III.

Attachments

Attachment-I : Flexibles pipes receipt checklist.

Attachment-II : Flexible pipes issuance record.

Attachment-III : Flexible pipe usage, checking and disposal record.

Attachment-IV : Scrap Transfer Request.

Abbreviations

QA : Quality Assurance

MOC : Material of Construction

PVC : Polyvinyl Chloride

Sr. No. : Serial Number

SS : Stainless steel

EHS : Environment, Health and Safety

RESPONSIBILITY:

User Department:

Shall be responsible for raising indent, checking and cleaning after receipt and during usage.

REVISION HISTORY

| Version No. | 00 | Effective Date | |

| Details of revision: New SOP Prepared | |||

Attachment-I