Calibration & Verification Of Analytical Balance

1.0 Objective

To lay down a guidelines for Calibration & Verification of Analytical Balance in Quality Control Department.

2.0 Scope

This SOP applies to Calibration of Analytical Balance used in Quality control Lab in abc company

3.0 Responsibility

3.1 Executive – Quality Control.

3.2 In charge/Head.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

QC : Quality Control

CC NO : Change Control Number

cGMP : Current Good Manufacturing Practice

C : Calibration

SD : Standard deviation

gm. : Gram

5.0 Procedure

5.1 Handling of Weight Box

5.1.1 Store the weight box in dust free area.

5.1.2 Do not touch the weight with bare hand, for handing the weight use a forceps.

5.1.3 Use certified weights only.

5.1.4 For cleaning of weights use a lint free cloth moistened with small amount of Di-ethyl ether and air dry.

5.1.5 Do not drop the weight on the pan to avoid any damage to the balance. Gently place the weight on the center

of the pan to eliminate comer weighing differences.

5.2 General Instruction

5.2.1 Clean the pan and Plat form of the balance after weighing is over.

5.2.2 Do not over load the balance of their maximum capacity.

5.2.3 Keep doors of the balance always closed.

5.2.4 Before closing and opening, ensure that the pan is empty.

5.2.5 Keep the balance in “STAND BY” position when not in use, by pressing I/Q’ key of the balance.

5.3 Cleaning

5.3.1 Before cleaning, disconnect the balance from the power supply.

5.3.2 Do not use any aggressive cleaning agents or strong solvents.

5.3.3 Use a piece of cloth which has been wet with a mild detergent (soap) to clean the weighing pan and balance housing.

5.3.4 Make sure that no liquid enters the balance housing.

5.3.5 After cleaning, wipe down the balance with a soft, dry piece of cloth.

5.3.6 Carefully remove any sample residue/ spilled powder by using a brush that is placed with the balance.

5.4 Daily verification of Analytical Balance

5.4.1 Internal calibration (Self-calibration/ Auto calibration)

5.4.1.1 Press “CAL” key. Balance will go into automatic self calibration mode and “CAL” will be displayed,

the “CC” will be displayed after self calibration is over display will show 0.000 g, then balance is

ready for use. Record the observation in the given Annexure-1.

5.4.2 With Secondary standard weight

5.4.2.1 Calibration the balance daily with the standard weights of 1 g, 10g, 100 g & 200 g individually. Record

the results as given in Annexure-1.

5.4.2.2 Acceptance Criteria: ±0.1% of the Certified weight.

5.5 Monthly Calibration od Analytical Balance

5.5.1 Measurement of Uncertainty

5.5.1.1 Ensure that the standard weights used are within the validity period of its calibration.

5.5.1.2 The weights selected for uncertainty measurement are 1 g, 5 g & 10 g.

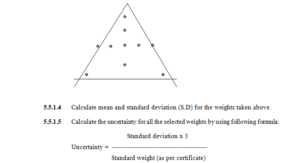

5.5.1.3 Measure the weights by keeping the standard weight at the positions (10 times, individually)

as given in the following diagram.

5.5.1.6 Acceptance criteria for uncertainty measurement: NMT-0.001

5.5.1.7 Record the observations in annexure-2.

5.5.2 Calibration with standard weights

5.5.2.1 Place 1 g certified weight in the center of the pan. Close the door.

5.5.2.2 Wait until the weighing result is stable.

5.5.2.3 Now read the displayed weight.

5.5.2.4 Take out the 1 g weight and allow the balance to come to zero.

5.5.2.5 Repeat the above procedure for the certified weights of 2g, 5g, 10g, 20g, 50g, 100g and 200g.

5.5.2.6 Record the observations in annexure-2.

5.5.2.7 Acceptance Criteria: ±0.1% of the certified weight.

6.0 Forms and Records

6.1 Daily verification record of Analytical Balance – Annexure-1

6.2 Monthly calibration of Analytical Balance – Annexure-2

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Control copy – Quality Control

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

Operating Procedure of Centrifuge

sop for preparation and storage of reagent solution

sop for Calibration and Maintenance of Laboratory Instruments and Equipment

Disposal of Residual Sample or Left Over Material

sop for for Laboratory Incident

standard operating procedure temperature monitoring

sop for operation of infrared moisture balance

sop for preparation of mobile phase

sop for Preparation and Issuance of Analysis protocol standard

sop of placebo and impurity stock solutions

sop for disposal of residual sample

sop for handling of pharmacopoeial changes

sop for procedure for operation of ultrasonic cleaner

difference between UPLC and HPLC

sop for for Emergency Eyewash and Shower

sop for operation and calibration of total organic carbon analyzers

sop for operation of cobb tester

sop for Operation and calibration of atomic absorption spectrophotometer

sop for Operation and calibration of gas liquid chromatograph

sop for operation of humidity oven

sop for operation and calibration of serological water bath

sop for monitoring of drain trap

sop for destruction of analytical samples after testing and control samples

sop for destruction of used chemicals

Sop for Operation of suction pump

sop for Operation and calibration uv cabinet

sop for Operation and calibration of bulk density apparatus

sop for operation and calibration of shore hardness tester

sop for operation of rub proofness tester

sop for monitoring of purified water

sop for Retesting of packaging materials

sop for Retesting and resampling of raw materials

sop for Control of issuance of record of analysis green sheets

sop for Control of computer passwords

sop for sampling of packaging materials PM