Sop cleaning of uniform

1. PURPOSE & SCOPE: To laydown the procedure for cleaning of uniform.

2. RESPONSIBILITY

Personnel officer

3. AUTHORITY

Factory manager

4. PROCEDURE

The following uniforms are used in the plant.

A. Smoke coat for all production and packing Workers/Officers/Managers.

B. Aprons for all the Supervisor/Officers/Managers and Q.C.D. Staff.

C. Front opening overhauls for maintenance staff.

Apart from these all personnel use clean rubber slippers and caps.

Cleaning of all these are done on regular basis so that everybody wears clean and dry uniforms daily. For the purpose adequate extra sets are kept ready.

CLEANING PROCEDURE

A) Garments including caps, smoke coats, trousers, aprons and overhauls are washed twice in a week laundry machine

with detergents and is contracted to an outside agency. The dried uniform is received ironed and stored in the uniform cabinet/lockers.

As the plants in nit having its own laundry unit, the uniform cleaning is done by outside agency following the same procedure.

B) Rubber slippers are soaked in plastic tubs containing 0.5% teepol solution

in water for over night. Next Morning they are brushed and cleaned with

water. Slippers are then dried and kept in the racks.

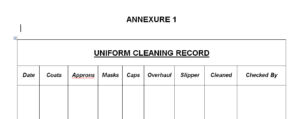

The record in this effect is maintained as per the format given in annexure 1

In case any uniform is contaminated by vomiting, bleeding etc., it is soaked in boiling water containing 20%

Dettol for 2 hrs. After this the wash water in strained out and the garment is sent for normal washing and ironing from an outside agency.