sop for Operation of Bore Well

1.0 Objective

To lay down procedure for Operation of Bore Well.

2.0 Scope

This Standard Operating Procedure is applicable for Operation of Bore Well, to be followed at formulation plants

3.0 Responsibility

3.1 Officer / Executive Engineering shall be responsible for the execution of this procedure.

3.2 Engineering Manager shall be responsible for the implementation of this SOP.

3.3 Head QA/ designee shall be responsible for the compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

No : Number

NA : Not Applicable

Lit. : Litre

PPM : Parts per million

MGF : Multi Grade Filter

HDPE : High Density Polyethylene

ER : Engineering

5.0 Procedure

5.1 Ensure that the Sodium hypochlorite dosing pump switched ON and HDPE tank is filled

With Sodium hypochlorite solution.

5.2 Ensure the validity of the sodium hypochlorite solution used for chlorine dosing. It shall not

Be more than 24 hours.

5.3 Start the bore well by pressing the green button in starter and Starter mounted at main panel.

5.4 Operate the MGF as per SOP

5.5 Check the chlorine level in the water as per SOP It should be between 2 to 3 PPM.

5.6 Check for the clarity of the water visually by taking 50 ml sample in a clean beaker at before

And after MGF.

5.7 If water is not clear, backwash the multi grade filter as per SOP

5.8 It takes to fill up the tank around 25 hours.

5.9 Switch off the bore well and MGF by pressing the red button in Starter and Starter Mounted

Main panel.

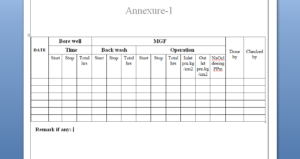

5.10 Record the details of operation in Bore well operation Record as per Annexure-I.

6.0 Forms and Records

6.1 Bore well Operation record – Annexure-1

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Engineering Department.

Nice site, looks very organized. Finally found what Ive been looking for, thanks!