sop for preventive maintenance of Vibro-Sifter

1.0 Objective

To lay down a procedure for the Preventive Maintenance of Vibro Shifter.

2.0 Scope

This Standard Operating Procedure is applicable for the Preventive Maintenance of Vibro Sifter to be followed at formulation plants

3.0 Responsibility

3.1 Engineering Officer / Executive shall be responsible for the execution of this procedure.

3.2 Engineering Manager shall be responsible for the implementation of this SOP.

3.3 Head QA/designee shall be responsible for compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure etc

No : Number

QA : Quality assurance

Qty. : Quantity

ER : Engineering

5.0 Procedure

5.1 General Conditions

5.1.1 Refer the master plan of preventive maintenance.

5.1.2 Equipment shall be available for preventive maintenance.

5.1.3 Clean oil / grease stains & remove unwanted material, spares .

5.2 Precautions

5.2.1 Use necessary safety wears, while doing the work.

5.2.2 Ensure covers & guards are properly fixed.

5.3 Procedure for Preventive Maintenance of Vibro Sifter.

5.3.1 Ensure that electrical supply is in off position in main panel and display “Under Maintenance” Board on the panel board.

5.3.2 Switch “OFF” the drive unit and inform all the concerned.

5.3.3 Operator or above has to ensure and verify the check points for the preventive maintenance as shown in Annexure-1.

5.3.4 After the completion of preventive maintenance, check the machine for smooth operation.

5.3.5 Remove “Under Maintenance” Board on the panel board after completion of the Maintenance.

5.3.6 The operator / technician who perform the job will enter his name in ”Done By” Column and responsible Engineer/ Officer and Officer – Production will put sign in “Checked by” column.

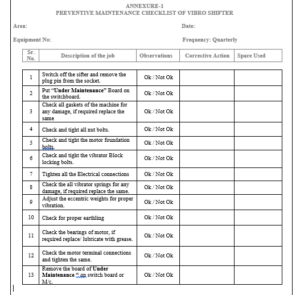

5.4 Quarterly Preventive Maintenance is to be carried out as per the following check points

5.4.1 Check all gaskets of the machine for any damage, if required replace the same.

5.4.2 Check and tight all nut bolts.

5.4.3 Check and tight the motor foundation bolts.

5.4.4 Check and tight the vibrator Block locking bolts.

5.4.5 Tighten all the electrical connections.

5.4.6 Check the all vibrator springs for any damage, if required replace the same.

5.4.7 Adjust the eccentric weights for proper vibration.

5.4.8 Check for proper earthing.

5.4.9 Check the bearings of motor, if required replace/ lubricate with grease.

5.4.10 Check the motor terminal connections if required tighten the same.

6.0 Forms and Records

6.1 Quarterly Preventive Maintenance Check list of Vibro Shifter Annexure-1

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Engineering Department