1.0 Objective: To describe the procedure for operation and cleaning of paste kettle.

2.0 Scope: This procedure is applicable to paste kettle

3.0 Responsibility: Operator / Production Officer / Executive

4.0 Accountability: Department Head shall be accountable for the compliance of the system.

5.0 Procedure:

5.1 Operation:

5.1.1 Check the cleanliness of the Paste kettle.

5.1.2 Check and ensure that the lower paste discharge valve is in closed position.

5.1.3 Ensure steam supply is disconnected.

5.1.4 Transfer the required quantity of purified water as per BMR for the respective product into the bowl.

5.1.5 Drain water from the pipe and start the steam supply and boil the water.

5.1.6 Prepare the paste as per the instruction given in BMR for the product.

5.1.7 Stir intermittently with under stirring.

5.1.8 After completion of the paste preparation close the steam valve.

5.1.9 Open the general water circulation valve for cooling of the paste as per requirement of BMR and after achieving the required temperature close the water circulation valve.

5.1.10 Place a container below the discharge point and transfer the whole or part by opening the discharge valve.

5.1.11 After the completion of work affix “To be cleaned” label on it.

5.1.12 Record the activity in logbook.

5.2 Cleaning:

5.2.1 Keep a container below the discharge valve.

5.2.2 Wash with general water by scrubbing with a nylon brush and then wash with Hot water followed by sufficient purified water to remove. Swipe it with clean dry lint free cloth.

5.2.3 Clean the remaining parts of the machine with a wet cloth followed by clean dry lint free cloth.

5.2.4 Mop the inner part of the bowl with IPA.

5.2.5 Clean the surrounding area with Hot water Affix “Cleaned” label on the machine.

5.2.6 Record the same in logbook.

6.0 Abbreviations:

| Abbreviation | Expanded Form |

| SOP | Standard Operating Procedure |

| PR | Production |

| QA | Quality Assurance |

| IPA | Isopropyl Alochol |

| BMR | Batch Manufacturing Record |

7.0 Forms and Attachments:

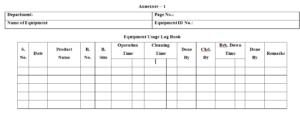

Annexure – 1: Equipment Log Book

8.0 Distribution List:

| S. No. | Department Name | No. of Copy |

| 1. | Quality Assurance | 01 |

| 2. | Production | 01 |

9.0 References:

In – House