sop on operation and cleaning of mass mixer

1.0 Objective: To describe the procedure for operation and cleaning of Mass mixer.

2.0 Scope: This procedure is applicable to mass mixer

3.0 Responsibility: Operator / Production Officer / Executive

4.0 Accountability: Department Head shall be accountable for the compliance of the system.

5.0 Procedure:

5.1 Operation:

5.1.1 Check the cleanliness of the area and machine. There should not be any traces of the previous product.

5.1.2 Get the line clearance from Q.A. Open the lid of the machine by pulling the knob which is on the panel board.

5.1.3 Load the materials as per the sequence given in BMR.

5.1.4 Switch on the main power supply. Close the lid by pressing the knob which is on the panel board. Keep the FBD bowl under the discharge valve of Mass mixer.

5.1.5 Start the dry mixing operation by pressing the button mentioning “slow” or as per the applicable BMR.

5.1.6 Add the paste as per the applicable BMR. Mix the paste uniformly slow speed by turning the knob at “slow” and then at fast by turning the knob at “fast”.

5.1.7 After completion of granules note down the Mass mixer.

5.1.8 Record the activity in sequential log book.

5.2 Cleaning: [At the Time of Product Change Over]

5.2.1 Cover the panel board, motor and all electrical connections with polythene bag.

5.2.2 Close the discharge valve. Clean the lid from top and bottom side with purified water.

5.2.3 Clean the impeller, and the bowl of Mass mixer with Hot water

5.2.4 and then with purified water to remove the traces

5.2.5 Fill the vessel with purified water and start the impeller at slow speed.

5.2.6 Open the discharge valve and discard water.

5.2.7 Rinse the vessel with purified water and call Q.A. person to collect the sample for analysis.

5.2.8 Uncover the panel board, motor and clean it with wet cotton cloth followed by dry lint free cloth. Dry the equipment with lint free cotton cloth.

5.2.9 Affix the “CLEANED” tag.

5.2.10 Record the activity in equipment log book.

5.3 Cleaning: [At the Time of Batch Change Over]

5.3.1 Clean the Mass mixer outside of with a dry lint free cotton cloth.

5.3.2 Remove the adhered materials inside the vessel as well as impeller by scrapping with a SS scrapper through discharge opening.

5.3.3 Record the activity in the equipment log book.

5.3.4 If the equipment is used for 6 batches or for 72 hrs (which ever is earlier) then clean the equipment as per the product change over.

5.3.5 If the equipment is kept idle for 48 hrs after cleaning then re-clean it before use.

6.0 Abbreviations:

| Abbreviation | Expanded Form |

| M.S | Mass mixer |

| SOP | Standard Operating Procedure |

| PR | Production |

| QA | Quality Assurance |

7.0 Forms and Attachments:

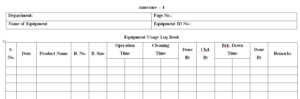

Annexure – 1: Equipment Log Book

8.0 Distribution List:

| S. No. | Department Name | No. of Copy |

| 1. | Quality Assurance | 01 |

| 2. | Production | 01 |

9.0 References:

In – House