1.0 Objective: To describe the procedure for operation and cleaning of fluidized bed dryer.

2.0 Scope: This procedure is applicable to fluidized bed dryer

3.0 Responsibility: Operator / Production Officer / Executive

4.0 Accountability: Department Head shall be accountable for the compliance of the system.

5.0 Procedure:

5.1 Operation:

5.1.1 Check the cleanliness of the area and machine. There should not be any remnants of the previous product.

5.1.2 Get the line clearance from Q.A. Check the integrity of the FBD sieve.

5.1.3 Switch on the main power supply; adjust outlet & inlet temperature as per BMR.

5.1.4 Drill down the finger bag hanging assembly with the help of wire rope. Put the SS rim in its position and fix the lower portion of the FBD bag and then fit it.

5.1.5 Take the finger bag hanging assembly in upward direction with the help of SS wire rope and fix it in the clamp.

5.1.6 Fix the upper trolley bowl on the stand and then fix it with the help of gaskets.

5.1.7 Unload the granules in the FBD bowl and insert in the FBD chamber.

5.1.8 Push the switch of FBD ‘on’ on FBD panel.

5.1.9 Set up the shaking time during operation.

5.1.10 After completion of an operation as per applicable BMR, wheel out the FBD bowl and check granules.

5.1.11 Put ‘To Be Cleaned’ label on it.

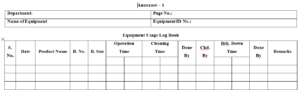

5.1.12 Record the activity in equipment log book.

5.2 Cleaning :

5.2.1 Batch to Batch cleaning:

5.2.2 Clean the outer surface of FBD chamber, bowl and panel board with lint free cotton cloth.

5.2.3 Clean the surrounding area with vacuum cleaner and then with Hot water

5.3 Cleaning: (Product Change Over)

5.3.1 Switch off the main power supply.

5.3.2 Remove the bowl from the FBD.

5.3.3 Dismantle the upper bowl. Drill down the FBD bags hanging assembly with the help of SS wire rope.

5.3.4 Dismantle the FBD finger bag.

5.3.5 Put the FBD bag in polythene bag; affix a “TO BE CLEANED” label on it.

5.3.6 Transfer the FBD bag into washing area. Clean it as per respective SOP.

5.3.7 Clean the upper and lower bowls with Hot water by scrubbing with nylon brush.

5.3.8 Clean the outer surface, inner surface of the retarding chamber and bowl of FBD with purified water.

5.3.9 Finally wash with sufficient purified water to remove the traces of previous product.

5.3.10 Swipe the above with a clean dry lint free cloth followed by IPA solution.

5.3.11 Affix a “CLEANED” label on it.

5.3.12 Record the activity in sequential log book.

5.3.13 Refix the cleaned fingure bag in the FBD. Keep the trolley under the FBD as above and run the dryer empty for 10 minutes with air only and 10minutes at temperature 400C.

5.3.14 Dismantle the dried fingure bag from the FBD and preserve it in a clean polybag with identification mark for the respective product.

5.3.15 If the equipment is used for 6 batches or for 72 hrs (which ever is earlier) then clean the equipment as per the product change over.

5.3.16 If the equipment is kept idle for 48 hrs after cleaning then re-clean it before use.

6.0 Abbreviations:

| Abbreviation | Expanded Form |

| SOP | Standard Operating Procedure |

| PR | Production |

| QA | Quality Assurance |

| FBD | Fluidized Bed Dryer |

| SS | Stainless Steel |

7.0 Forms and Attachments:

Annexure – 1: Equipment Log Book

8.0 Distribution List:

| S. No. | Department Name | No. of Copy |

| 1. | Quality Assurance | 01 |

| 2. | Production | 01 |

9.0 References:

In – House