ANALYTICAL METHOD VALIDATION PROTOCOL FOR BENZYL ALCOHOL BY HPLC

| Name of Product | BENZYL ALCOHOL

|

| Parameter | Analytical Method Validation for Benzyl Alcohol by HPLC |

| Method followed | By HPLC |

| Supersede No. | Nil |

| Total No of pages | |

| Effective Date |

| Sr. No. | Title | Page |

| — | Product Description | |

| — | Table of contents | |

| 1.0 | Document Preparation and Protocol Approval | |

| 2.0 | Revision Control History | |

| 3.0 | Objective | |

| 4.0 | Scope | |

| 5.0 | Reason For Validation | |

| 6.0 | Responsibility | |

| 7.0 | Description of Method Belonging | |

| 8.0 | Training Details | |

| 9.0 | Details of Analytical Method | |

| 10.0 | Chromatographic Conditation | |

| 11.0 | Performance Parameter of Validation | |

| 12.0 | Selection of Analytical Parameter Performs | |

| 13.0 | Specificity (Selectivity) | |

| 14.0 | Precision | |

| 15.0 | Table for sample assay | |

| 16.0 | Inter Mediate Precision | |

| 17.0 | Accuracy (Recovery) | |

| 18.0 | Sample Sequence of Accuracy | |

| 19.0 | Linearity | |

| 20.0 | Acceptance criteria | |

| 21.0 | References | |

1.0 DOCUMENT PREPARATION AND PROTOCOL APPROVAL

Preparation and Approval of this Analytical Method Validation document will be joint responsibility of the following functional area. Any modification in this document shall be documented and approved.

1.1 Prepared By:

| Name | Designation | Signature | Date |

| Executive – QC |

1.2 Reviewed By:

| Name | Designation | Signature | Date |

| Executive – QC | |||

| Manager – QC |

1.3 Approved By

| Name | Designation | Signature | Date |

| Head – QA |

2.0 Revision Control History:

| Effective Date | Version no. | Superseded no. | CCF no. | Reason for Review |

| 00 | Nil | NA | New documents |

OBJECTIVE:

To perform Analytical method Validation of Benzyl Alcohol and provide documentary evidence that the method used for Analytical method Validation of said product full fill the regulatory & compendia requirement. This protocol presents and discusses the result obtained in the Verification study for the parameter namely Specificity, System Suitability, Precision (Repeatability), Accuracy, Linearity, the test method.

4.0 SCOPE:

This document is applicable for the Analytical method Validation of HPLC Method which is applying for the Determination of Analytical validation for Benzyl Alcohol, to be manufactured at

Fast Pharma Pvt. Ltd.

5.0 REASON FOR VALIDATION:

Regulatory Requirement

6.0 RESPONSIBILITY:

The following functions are involved in the Analytical method Validation performing & shall carry out the following responsibilities.

6.1 Quality Control:

6.1.1 Officer & Executive Quality Control: To perform the analysis in the Verification and evaluate the data as per protocol.

6.1.2 Sr. Officer: To prepare the protocol and review all data evaluated as per protocol.

6.1.3 Manager Quality Control: To provide technical support, review the protocol and ensure that all parameter performed as per protocol.

6.2 Regulatory:

6.2.1 To provide technical support, review and approved the protocol and ensure that all parameter performed as per protocol.

7.0 DESCRIPTION OF METHOD BELONGING:

7.1 Product Detail:

7.1.1 Name of Product: BENZYL ALCOHOL

7.1.2 Generic Name: BENZYL ALCOHOL

7.2 Method Details:

Methodology: High performance liquid chromatography

8.0 TRAINING DETAILS:

Training shall be imparted to all concern persons involved in Analytical method validation activity w.r.t. cGMP & concerned analytical technique required for analysis & details will be attached in analytical method verification report’ activity, as per below mentioned format.

8.0 TRAINING DETAILS:

Training shall be imparted to all concern persons involved in Analytical method validation activity w.r.t. cGMP & concerned analytical technique required for analysis & details will be attached in analytical method verification report’ activity, as per below mentioned format.

| Purpose | To train all personnel involved in the execution of this protocol | ||

| Topic | · Purpose

· Procedure · Method details · Acceptance criteria · Documentation etc. |

||

| S. No. | Name of Participants | Area of Operation | Sign/Date |

9.3 Reagents and Chemicals

| Sr. No. | Name of Reagent | Grade | Make | Lot No. |

| 1. | Methanol | |||

| 2. | Sodium Acetate |

Diluent: Buffer and Methanol (30:70)

Standard solution:

Dissolve 100 mg of benzyl alcohol RS in the mobile phase and dilute to 100 ml with the mobile phase. Dilute 5 ml of this solution to 50 ml with the mobile phase.

Test solution:

Dissolve 100 mg of benzyl alcohol in the mobile phase and dilute to 100 ml with the mobile phase. Dilute 5 ml of this solution to 50 ml with the mobile phase.

9.4 Chromatographic Condition:

Column Dimension: a stainless steel column 25 cm × 4.6 mm, packed with octadecylsilane bonded to porous silica (5µm),

Buffer: Dissolve 20.4 gm. Of sodium acetate 1000 ml of with water.

Mobile phase: Buffer and Methanol (30:70).

Flow rate: 1.0 ml per minute.

Wave length: 254 nm

Injection volume: 20 µl.

System suitability:

Samples: Inject the Standard solution and the test solution

Suitability requirements:

Relative standard deviation: ……………….not more than 2% for Benzyl Alcohol standard solution.

Tailing Factor: …………….. not more than 2.0, Standard solution

Analysis Samples: Standard solution and Sample solution.

5 Calculation:

Ondansetron

Area of test wt. of std. 5 100 50 Potency

—————–× ————— ×——× —————————–× ——–× ————-× 100

Area of std. 100 50 sample 5 100

. std 5 100 50 Potency

—————–× ————— ×——× —————————–× ——–× ————-× 100

100 50 sample 5 100

10.0 Performance Parameter of Validation:

| Sr. No. | Performance Parameter |

| 1. | Specificity, System Suitability, méthode Precision (Repeatability) System precision & Inter mediate precision, Accuracy, and Linearity. |

SELECTION OF ANALYTICAL PARAMETER PERFORMS:

To the validation of the HPLC method used for the determination of Assay of Benzyl alcohol the following parameters should be performing.

11.1 Specificity (Selectivity):

Purpose: To establish Specificity of test method and to demonstrate its ability to assess unequivocally the Analyte in the presence of components which may be expected to be present? It ensures that there is no interference from Excipients and /or degradation products and /or impurities or the Analyte with each other

• Study Design: Demonstrate the Specificity of the test method by Injecting Blank, Standard solution & test solution.

• Chromatographic Condition: …………………………………………………As per methodology.

• Blank: …………………………Diluent

• Diluent: ………………………………………Buffer and Methanol (30:70)

• Standard solution: Dissolve ————- 100 mg of benzyl alcohol RS in the mobile phase and dilute to 100 ml with the mobile phase. Dilute 5 ml of this solution to 50 ml with the mobile phase.

• Test solution: Dissolve ————- 100 mg of benzyl alcohol in the mobile phase and dilute to 100 ml with the mobile phase. Dilute 5 ml of this solution to 50 ml with the mobile phase

The Observations are tabulated below

| Sr. No. | Type of Solution | Retention Time | Area |

| 1. | Blank | ||

| 2. | Standard solution | ||

| 3. | Test solution |

• Data Evaluation: Each chromatogram shall be processed & peak areas shall be calculated & reported.

• Acceptance Criteria: RSD of five replicate injections should not be more than 2.0 %.

• System Suitability:

Tailing Factor: Not more than 2.0 for the Benzyl Alcohol peak, Standard solution.

RSD: NMT 2.0%, Standard solution.

• Conclusion: …………………………………………………………………………………………..

…………………………………………………………………………………………..

…………………………………………………………………………………………..

11.2 Precision:

The Precision of an analytical procedure is the degree of agreement among individual test results when the procedure is applied repeatedly to multiple samplings of a homogeneous sample. The precision of an analytical procedure is usually expressed as the standard deviation (SD) or relative standard deviation (RSD) (Coefficient of variation) of a series of measurements. Precision may be a measure of either the degree of reproducibility or of repeatability of the analytical procedure under normal operating conditions.

11.2.1 SYSTEM PRECISION:

• Diluent, standard solution and chromatographic condition: Proceed as directed under point no. 9.0.

• Procedure: five replicate injections of standard preparation shall be chromatogram as per analytical method.

• Calculation: Calculate the relative standard deviation for replicate injections is not more than 2.0%.

• Conclusion: ………………………………………………………………………………………..

11.2.2 METHOD PRECISION:

A) Repeatability:

• Purpose: The Purpose of method Precision is to evaluate & demonstrate the precision of Analytical method under the same operating conditions over a short interval of time.

• Study Design: The assay is determined of 6 test solutions at 100% concentration representing a precision of method evaluated by % RSD of assay Results.

• Chromatographic Condition: ………………………………………………As per methodology.

• Diluent, standard solution, chromatographic condition and procedure: Proceed as directed under point no. 9.0.

• Test Solution: Six assay preparations of the sample shall be prepared as per the Analytical method.

The Observations are tabulated below:

| Sr. No. | Standard No. | Area |

| 01. | Standard Solution -1 | |

| 02. | Standard Solution -2 | |

| 03. | Standard Solution -3 | |

| 04. | Standard Solution -4 | |

| 05. | Standard Solution -5 | |

| Average | ||

| %RSD |

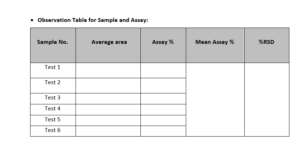

- Observation Table for Sample and Assay:

| Sample No. | Average area | Assay % | Mean Assay % | %RSD | |

| Test 1 | |||||

| Test 2 | |||||

| Test 3 | |||||

| Test 4 | |||||

| Test 5 | |||||

| Test 6 |

• Data Evaluation: The Relative Standard Deviation (RSD) of Assay of six preparations shall be calculated and reported.

• Acceptance criteria: RSD of Assay of six preparations should not be more than 2.0 %.

• System suitability:

Tailing Factor: _____________ not more than 2.0 for the Benzyl Alcohol peak, system suitability solution.

RSD: _____________ not more than 2.0%, Standard solution.

• Conclusion: ………………………………………………………………………………………..

11.2.3 INTER MEDIATE PRECISION

• Purpose: The Purpose of method Precision is to evaluate & demonstrate the precision of Analytical method under the same operating conditions over a short interval of time.

• Study Design: The assay is determined of 6 test solutions at 100% concentration representing a precision of method evaluated by % RSD of assay Results.

• Chromatographic Condition: ………………………………………………As per methodology.

• Diluent, standard solution, chromatographic condition and procedure: Proceed as directed under point no. 9.0.

• Test Solution: Six assay preparations of the sample shall be prepared as per the Analytical method.

• The Observations are tabulated below:

| Sr. No. | Standard No. | Area |

| 01. | Standard Solution -1 | |

| 02. | Standard Solution -2 | |

| 03. | Standard Solution -3 | |

| 04. | Standard Solution -4 | |

| 05. | Standard Solution -5 | |

| Average | ||

| %RSD |

- Observation Table for Sample and Assay:

• Data Evaluation: The Relative Standard Deviation (RSD) of Assay of six preparations shall be calculated and reported.

• Acceptance criteria: RSD of Assay of six preparations should not be more than 2.0 %.

• System suitability:

Tailing Factor: _____________ not more than 2.0 for the Benzyl Alcohol peak, system suitability solution.

RSD: _____________ not more than 2.0%, Standard solution.

• Conclusion: ………………………………………………………………………………………..

12.0 Accuracy (Recovery) :

• Purpose: The Purpose of Accuracy of test method is to evaluate & demonstrate the closeness of agreement between the value which is accepted either as a conventional true value or an accepted reference value and the value found.

• Study Design: The accuracy is demonstrated by preparing recovery samples (i.e. spiking known qty. of API) at a level of 50 %, 100 % & 150 % of sample concentration at Triplicate in each level.

• Chromatographic Condition: As per methodology.

• Diluent, standard solution, chromatographic condition and procedure: Proceed as directed under point no. 9.0.

• Test Solution: Benzyl Alcohol at three different levels 50 %, 100 % and 150 % of test concentration in triplicate (i.e. total nine determinations) covering the specified range and analyzed as described under methodology.

• Sample Sequence for Accuracy:

| Sample Name | Number of Injection | Injection Volume | Run Time |

| Blank | 1 | 20µl | |

| Standard solution | 5 | 20µl | |

| Test solution | 3 different level (duplicate in each level) | 20µl | |

| Standard solution Bkt. | 1 | 20µl |

- The Observations are tabulated below :

| Sr. No. | Standard No. | Area |

| 01 | Standard Solution -1 | |

| 02 | Standard Solution -2 | |

| 03 | Standard Solution -3 | |

| 04 | Standard Solution -4 | |

| 05 | Standard Solution -5 | |

| Average | ||

| %RSD |

• The observation are tabulated in table:

| Recovery level | Set No. | Peak Average area | Recovery

(%) |

Ave.

(%) |

RSD

(%) |

| 50% | |||||

| 100 % | |||||

| 150 % |

• Data Evaluation: The Relative Standard Deviation (RSD) of Assay of three preparations shall be calculated and reported.

• Acceptance criteria: RSD of Assay of three preparations should not be more than 2.0 %.

• System suitability:

Tailing Factor: ______________ not more than 2.0 for the Benzyl Alcohol peak, system suitability solution.

RSD: _________________ not more than 2.0%, Standard solution.

• Conclusion: …………………………………………………………………………………………..

13.0 Linearity:

• Purpose: The Purpose of Linearity testing of analytical procedure is to demonstrate its ability (within a given range) to obtain test results which are directly proportional to the concentration (amount) of analyte in the sample.

• Study Design: Demonstrate the Linearity of the test method Blank & Stock solution (given below). A series of standard solutions shall be prepared (minimum of five preparations) over a range of 50 % to 150 % of the standard concentration Benzyl Alcohol

• Chromatographic Condition: As per methodology.

• Diluent, standard solution, chromatographic condition and procedure: Proceed as directed under point no. 9.0.

• Standard solution: Dissolve ————- 100 mg of benzyl alcohol RS in the mobile phase and dilute to 100 ml with the mobile phase. Dilute 5 ml of this solution to 50 ml with the mobile phase the mobile phase.

• Test solution: Dissolve ————- 100 mg of benzyl alcohol in the mobile phase and dilute to 100 ml with the mobile phase. Dilute 5 ml of this solution to 50 ml with the mobile phase phase

• Sample Sequence for Linearity:

| Linearity Level | Sample Name with Conc. In µg/ml | Stock Solution | Diluted to volume | Injection Volume | No. of Injection | Run Time |

| — | Blank | — | — | 20µl | 01 | |

| — | Standard Solution | — | — | 20µl | 05 | |

| 50 % | Linearity -50 ppm | 2.5 ml | 50 ml | 20µl | 01 | |

| 80 % | Linearity -80 ppm | 4.0 ml | 50 ml | 20µl | 01 | |

| 100 % | Linearity 100 ppm | 5.0 ml | 50 ml | 20µl | 01 | |

| 120 % | Linearity -120 ppm | 6.0 ml | 50 ml | 20µl | 01 | |

| 150 % | Linearity -150ppm | 7.5 ml

ml |

50 ml | 20µl | 01 |

• Data Evaluation: Inject above solution into HPLC System & record the area of Analyte peak. Plot a graph of concentration (in X-Axis) Vs Analyte peak area (in Y-Axis) and the Correlation coefficient reported.

• Acceptance criteria: The Correlation coefficient should be not less than 0.995.

• System suitability:

• Tailing factor: ______________ not more than 2.0 for the Benzyl Alcohol peak, system suitability solution.

• RSD: ______________ not more than 2.0%, Standard solution.

• Conclusion: …………………………………………………………………………………………..

14.0 ACCEPTANCE CRITERIA:

| Sr. No. | Title | Acceptance Criteria | Observations/Conclusions | |

| 1. | Specificity | There shall be no interference from the peaks due to blank at the retention time of main ingredient. | ||

| 2. | Method Precision | |||

| 2.1 | Repeatability | RSD of assay of six preparations should not be more than 2.0 %. | ||

| 2.2 | System precision | RSD of assay of six preparations should not be more than 2.0 %. The relative difference from method precision should be not more than 2.0 %. | ||

| 2.3 | Inter Mediate Precision | RSD of assay of six preparations should not be more than 2.0 %. The relative difference from method precision should be not more than 2.0 %. | ||

| 3. | Accuracy | Average recovery at each respective level within 95.0% to 105.0% and RSD of Triplicate recovery results should be not more than 2.0%. | ||

| 4. | Linearity | The Correlation coefficient should be not less than 0.995. | ||

| 5. | Accuracy(Recovery) | RSD of assay of 3 preparations should not be more than 2.0 %. | ||

15.0 REFERENCES:

ICH Guidelines

WHO Guidelines

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipment

concurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection