cleaning validation maco and noel calculation formula

INTRODUCTION OF CLEANING VALIDATION:

The cleaning validation is to verify the effectiveness and consistency of the cleaning procedure for removal of product

residues as well as the control of potential microbial contaminants in product. Selection of “Worst case” product is on the

basis of Potency, solubility, Toxicity and Pharmacological action of Active pharmaceutical Ingredients (API).

Three consecutive applications of the cleaning procedure shall be performed during cleaning validation to

justified effectiveness & reproducibility of the cleaning procedure.

If any product introduced or discontinue into the line then revise the product matrix and perform cleaning

validation accordingly if get any change in ‘Worst case’.

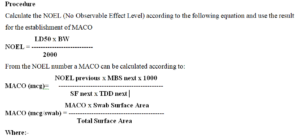

CALCULATION OF MAXIMUM ALLOWABLE CARRYOVER (MACO) in mg:

Cleaning Limit Selection Criteria based on Maximum Allowable Carryover (MACO).

Cleaning Limit Selection Criteria based on LD50 and Maximum Allowable Carryover (MACO).

The MACO can be based upon LD50 data.

Where:-

MACO Maximum Allowance Carryover: Acceptable transferred amount from the previous product into your next product (mg)

NOEL previous: No Observed Effect Level (mg/day)

LD50: Lethal Dose 50 in mg/kg animal. The identification of the animal (mouse, rat etc.) and the way of entry (IV, oral etc.) is important (mg/kg)

BW: Is the weight of an average adult (e.g. 70 kg) (kg)

2000: 2000 is an empirical constant

TDD next: Standard Therapeutic Daily Dose for the next product (mg/day)

MBS next: Minimum batch size for the next product (s) (where MACO can end up)

1000 = conversion of milligrams to micrograms

SF next Safety factor

The safety factor (SF) varies depending on the route of administration (see below).

Parenterals: 10000

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

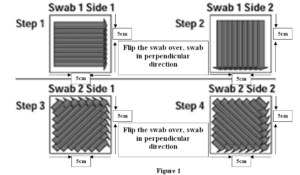

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipment

concurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Protocol for re validation of dry heat sterilizer