Sop for certification of authorised sterile entry

1.0 OBJECTIVE:

The objective of this SOP is:

1.1 To describe the procedure for Authorization and control of persons for entry to sterile area.

1.2 This is applicable for production Operators, Staffs, Q.C., Q.A. and Maintenance persons.

2.0 RESPONSIBILITIES:

2.1 Concerned Operator shall be:

2.1.1 Responsible to follow all the sterile area SOPs related to Entry/Exit, Operation and cleaning procedures.

2.2 Production Officer shall be:

2.2.1 Responsible for selection and training and monitoring of personnel.

2.3 Quality control shall be:

2.3.1 Responsible for prepare the required materials to evaluate the selected and trained personnel.

2.4 Quality Assurance shall be:

2.4.1 Responsible for authorize to allow the persons, recommended by Head of Department and evaluating data of microbiological monitoring.

3.0 ACCOUNTABILITY:

Head – Production & Head – Quality Assurance

4.0 PROCEDURE:

4.1 PRE-STEPS:

4.1.1 Check the last medical report of the selected person before the training.

4.1.2 All selected new operators, who are considered for sterile area entry and operations, have to under go training for the following SOPs by the production officer.

Sr. No. |

SOP Tittles |

SOP No. |

| 01. | Entry & Exit Procedure To The Sterile Area. | |

| 02. | Operating & Cleaning Of Dry Powder Filling | |

| 03. | Operating & Cleaning Of Vial Sealing Machine. | |

| 04. | Handling Hopper Left Over Powder And Primary Packaging Material. | |

| 05. | Operation And Cleaning Of LAF. | |

| 06. | Cleaning And Operation Of Dynamic Pass Box. | |

| 07. | Cleaning And Use Of Garment Cubicle. | |

| 08. | Procedure For Transfer Of Sterile Raw Material | |

| 09. | Cleaning And Sanitization Of Sterile Area. | |

| 10. | Procedure For Environmental Monitoring Of Sterile Area | |

| 11. | Operation Of Particle Counter. | |

| 12. | Fumigation Of Sterile Area. |

4.1.3 After completion of training, a person who is already qualified for sterile area working shall demonstrate the sterile gowning.

4.1.4 After training the production officer has to raise the requisition to QC for evaluation of that person.

4.2 START UP PROCEDURE:

4.2.1 After the demonstration the person shall be allowed to enter in sterile area, but shall not be allowed to carry out any operations

for three entries and during this three entries he will be monitored by microbiologist for “Monitoring of personnel in aseptic area” as per SOP

4.2.2 Once microbiologist qualifies the person he shall be allowed to enter and carry out the sterile area cleaning and sanitization work in

the guidance of qualified person.

4.2.3 He shall be allow carrying out this cleaning work consecutively for ten days, during those days he will be monitoring by microbiologist,

for Monitoring of personnel in aseptic area as per SOP

4.3 PROCEDURE:

4.3.1 Sectional head will monitor him for personal hygiene, behaviors and aseptic practices whenever required he will give on job training,

in these thirteen days working in sterile area.

4.3.2 On the basis of the observations of sectional head and the data of microbiologist the person shall be recommended by Head of production

for authorization of entry and working in sterile area to Head of QA.

4.3.3 After authorization of QA, the authorization card for sterile area will be provided to the qualified person and the list of Authorized persons

for sterile area entry shall be updated to add his name.

4.3.4 Microbiologist will regularly monitor all the qualified personnel as per the SOP .

4.3.5 The production officer/ IPQC officer will regularly monitor all the qualified personnel for hygiene, behavior and

aseptic processing if any abnormalities in microbiological report or sterile behavior observations the QA will disqualify the person.

4.4 PRECAUTIONS:

4.4.1 After authorized also the persons, who affected illness or communicable, skin diseases are prohibited for sterile entry.

4.4.2 All personnel who enter the aseptic processing area, including technicians and operating, Micro labs. Personnel shall be covered

in a media fill at least once in a year for re authorization.

4.4.3 All personnel shall re-qualify for gowning procedure with more sampling location at every six months during media fill.

5.0 REASON FOR REVISION:

New SOP.

6.0 TRAINING:

Trainer — Head – QA

Trainee — All Departmental Executives, Officers.

7.0 DISTRIBUTION:

Certified Copy : Head – Plant Operations

Reference Copy : For Display in Entry to the Sterile Area

Original Copy : Head – quality assurance

8.0 ANNEXURE:

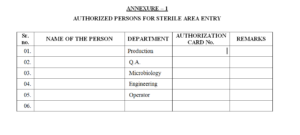

Annexure – 1: Authorized persons for sterile area Entry

9.0 REFERENCE:

US FDA, Guideline