sop for Status Labelling

1.0 OBJECTIVE :

1.1 To lay down a procedure for status labelling.

2.0. SCOPE :

2.1 This Standard Operating Procedure is applicable for all labelling operation done in production and warehouse

area to be followed at formulation plants of ABC Pharma Pvt. Ltd.

3.0. RESPONSIBILITY :

3.1 Officer / Executive of concern department shall be responsible for status labeling.

3.2 In-process Quality Assurance shall be responsible for verification of status label.

3.3 Concern department Head / Head QA / his designee shall be responsible for compliance of this SOP.

4.0. ACCOUNTABILITY: Concern department Head / Head QA

5.0 PROCEDURE :

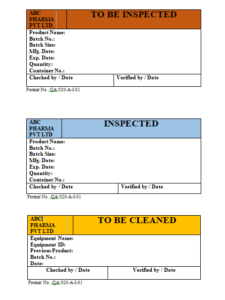

5.1.1 ‘TO BE INSPECTED’ status label shall be affixed on the container which contains materials ready for inspection.

5.1.2 Top most line of ‘TO BE INSPECTED’ status label contains ABC pharma Pvt. Ltd on left side (Annexure-1).

5.1.3 Data of the ‘TO BE INSPECTED’ status label shall be filled by Officer/Executive Production and cross verified by IPQA and affixed label on those containers in which material shall be kept for inspection.

5.1.4 ‘TO BE INSPECTED’ shall be written in black, capital and bold letters.

5.2 Status Labeling for Inspected

5.2.1 ‘INSPECTED’ status label shall be affixed on the container which contains inspected materials (Annexure-1).

5.2.2 Top most line of ‘INSPECTED’ status label contains ABC Pharma Pvt. Ltd on left side.

5.2.3 Data of the ‘INSPECTED’ status label shall be filled by Officer/Executive Production and cross verified by IPQA and affixed label on that containers in which inspected material shall be kept.

5.2.4 ‘INSPECTED’ shall be written in black, capital and bold letters.

5.3 Status Labelling for To Be Cleaned

5.3.1 Status label ‘TO BE CLEANED’ shall be affixed on the containers, equipments, utensils machines and areas which to be cleaned (Annexure-1).

5.3.2 Top most line of this label ‘TO BE CLEANED’ contains ABC Pharma Pvt. Ltd on left side.

5.3.3 Data of the ‘TO BE CLEANED’ status label shall be filled by operator and verified by Officer/Executive Production.

5.3.4 ‘TO BE CLEANED’ shall be written in black, capital and bold letters.

5.4 Status Labelling for In-process Status

5.4.1 ‘INPROCESS STATUS’ label shall be affixed on the containers which contains semi-finished or finished materials (Annexure-1).

5.4.2 Top most line of this label ‘INPROCESS STATUS’ contains ABC Pharma Pvt. Ltd on left side.

5.4.3 Data of the ‘INPROCESS STATUS’ status label shall be filled by Officer / Executive Production and cross verified by IPQA.

5.4.4 ‘INPROCESS STATUS’ shall be written in black, capital and bold letter.

5.5 Status Labelling for Status Label

5.5.1 ‘STATUS LABEL’ shall be used on the equipments, bins, machines and rooms, etc as per Annexure-1.

5.5.2 Top most line of this label ‘STATUS LABEL’ contains ABC Pharma Pvt. Ltd on left side and back ground shall be in white colour.

5.5.3 Data of the ‘STATUS LABEL’ status label shall be filled by Officer/Executive Production and cross verified by IPQA.

5.5.4 ‘STATUS LABEL’ shall be written in black, capital and bold letter.

5.6 Status Labelling for Cleaned

5.6.1 ‘CLEANED’ status label shall be affixed on the containers, equipments, utensils, machines and areas to indicate status of cleaning (Annexure-1).

5.6.2 Top most line of this ‘CLEANED’ status label contains ABC Pharma Pvt. Ltd on left side.

5.6.3 Data of the ‘CLEANED’ label shall be filled by operator and verified by Officer / Executive Production.

5.6.4 ‘CLEANED’ shall be written in black, capital and bold letter.

5.7 Status Labeling for Machine Status

5.8 Status Labelling for Loose Box

5.8.1 ‘LOOSE BOX’ status label shall be affixed on the box which contains loose semi-finished or finished materials (Annexure-1).

5.8.2 Top most line of this label ‘LOOSE BOX’ contains ABC Pharma Pvt. Ltd on left side.

5.8.3 Data of the ‘LOOSE BOX’ status label shall be filled by Officer/Executive Production and verified by IPQA and affixed on the loose box.

5.8.4 ‘LOOSE BOX’ shall be written in black, capital and bold letters.

5.9 Status Labelling for Under Maintenance

5.9.1 ‘UNDER MAINTENANCE’ status label shall be affixed on machine / equipment which shall be under maintenance (Annexure-1).

5.9.2 Top most line of this label ‘UNDER MAINTENANCE’ contains ABC Pharma Pvt. Ltd on left side.

5.9.3 Data of the ‘UNDER MAINTENANCE’ status label shall be filled by Officer/Executive Production and affixed on that machine / equipment which is under maintenance.

5.9.4 UNDER MAINTENANCE’ shall be written in black, capital and bold letters.

5.10 Status Labelling for Excess Material Return

5.10.1 ‘EXCESS MATERIAL RETURN’ status label shall be affixed on the unused material which is excess after completion of the process (Annexure-1).

5.10.2 Top most line of this label ‘EXCESS MATERIAL RETURN’ contains ABC Pharma Pvt. Ltd on left side.

5.10.3 Data of the ‘EXCESS MATERIAL RETURN’ status label shall be filled by Officer /Executive Production and verified by IPQA and affixed on the excess material to be return to store on material return note slip / MRN.

5.10.4 ‘EXCESS MATERIAL RETURN’ shall be written in black, capital and bold letters.

5.11 Status Labelling for Recoverable

5.11.1 ‘RECOVERABLE’ status label shall be affixed on the reuse material which is remain after completion of the process (Annexure-1).

5.11.2 Top most line of this label ‘RECOVERABLE’ contains ABC Pharma Pvt. Ltd on left side.

5.11.3 Data of the ‘RECOVERABLE’ status label shall be filled by Officer /Executive Production and verified by IPQA and affixed on the remaining material.

5.11.4 ‘RECOVERABLE’ shall be written in black, capital and bold letters.

5.12 Status Labelling for Non- Recoverable

5.12.1 ‘NON-RECOVERABLE’ status label shall be affixed on the waste material which is wastage during production (Annexure-1).

5.12.2 Top most line of this label ‘NON-RECOVERABLE’ contains ABC Pharma Pvt. Ltd on left side.

5.12.3 Data of the ‘RECOVERABLE’ status label shall be filled by Officer /Executive Production and verified by IPQA and affixed on the wastage material.

5.12.4 ‘NON-RECOVERABLE’ shall be written in black, capital and bold letters.

5.13 Status Labelling for Rejected

5.13.1 ‘REJECTED’ status label shall be affixed on the reject material which is rejected during operation of the product (Annexure-1).

5.13.2 Top most line of this label ‘REJECTED’ contains ABC Pharma Pvt. Ltd on left side.

5.13.3 Data of the ‘REJECTED’ status label shall be filled by Officer /Executive Production and verified by IPQA and affixed on the rejected material.

5.13.4 ‘REJECTED’ shall be written in black, capital and bold letters.

6.0. ABBREVIATION :

| Sr. No. | Abbreviation used | Full form of abbreviation used |

| 1. | SOP | Standard Operating Procedure |

| 2. | QA | Quality Assurance department |

| 3. | IPQA | In-Process Quality Assurance |

ATTACHMENTS (ANNEXES) :

Annex-I : Different Status Label

8.0. REFERENCE

| Sr. No. | Reference Title |

| 1.0 | Guide to Good Manufacturing Practice for Medicinal Products

|

Annex-I

Different Status Label

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipment

concurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

handling and investigation of Market Complaints