Measurement and Recording of Temperature and Relative Humidity

1.0 Objective

To lay down a procedure for measurement and recording of temperature and relative humidity.

2.0 Scope

This Standard Operating Procedure is applicable for measurement and recording of

temperature and relative humidity to be followed at formulation plants of ABC Pvt. Ltd.

3.0 Responsibility

3.1 Officer / Executive of concerned department shall be responsible for measurement and

recording of temperature and relative humidity.

3.2 Concerned department head shall be responsible for implementation of this SOP.

3.3 Head QA shall be responsible for compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

BPCR : Batch Production and Control Record

FG : Finished Goods

RH : Relative Humidity

QA : Quality Assurance

No. : Number

5.0 Procedure

5.1 Measurement of temperature and relative humidity with wet and dry thermo hygrometer

5.1.1 Officer / Executive of concerned department shall ensure that the thermo hygrometer is

calibrated and status tag of calibration is affixed on hygrometer.

5.1.2 Before monitoring the relative humidity, Officer / Executive shall ensure that the water

reservoir is filled with purified water so that wick remains wet.

5.1.3 Empty out the water reservoir every week and clean it properly.

5.1.4 After refilling with purified water in reservoir ensure that wick has wet completely and temperature gets stabilized.

5.1.5 Officer / Executive shall ensure that the wick is properly inserted in reservoir of thermo hygrometer.

5.1.6 Place the dry bulb/ wet bulb hygrometer in the area where temperature and relative humidity

to be monitor, keep the Psychometric chart and monitoring record near the hygrometer or in area.

5.2 Monitor the relative humidity as per the procedure given below

5.2.1 Read the dry bulb temperature and wet bulb temperature in °C visually by seeing

the mercury level of the thermometer.

5.2.2 Calculate the difference between dry bulb and wet bulb temperature.

5.2.3 See the deference against dry bulb temperature in psychometric chart and read the relative humidity.

5.3 Monitoring of temperature and relative humidity by using digital thermo hygrometer

5.3.1 Officer / Executive shall ensure that the digital thermo hygrometer is duly calibrated

and status tag of calibration is affixed on digital thermo hygrometer.

5.3.2 Place the digital thermo hygrometer in the area where temperature and humidity record is to be monitor.

5.3.3 Officer / Executive shall ensure that thermo hygrometer shall be placed in a location where

there is no disturbance from machine vibration, water spillage or any other disturbances.

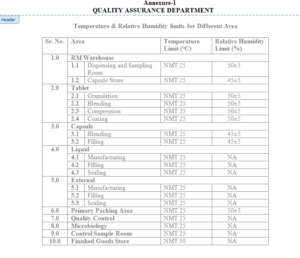

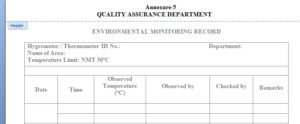

5.4 Refer the temperature and relative humidity limit for specified location as mentioned in

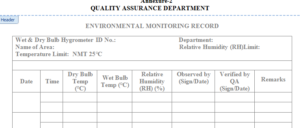

Annexure-1 and record the observation in Annexure-2 for area where the wet thermo

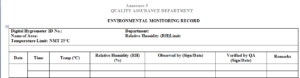

hygrometer is placed, refer Annexure-3 for recording where digital thermo hygrometer is used

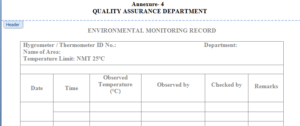

and refer Annexure-4 & Annexure-5 for recording the temperature of area where the relative

humidity not applicable there shall be the remain ambient humidity.

5.5 Monitor the temperature and relative humidity of the area at the frequency of twice in a

shift, i.e. at the start of the shift and at the end of the shift and record the same in

format as shown in Annexure-2 to Annexure-5.

5.6 In case a product specific, temperature & relative humidity are mentioned in BPCR,

the same shall be maintained and recorded in BPCR.

5.7 Temperature shall be read visually by observing the mercury level of the

dry bulb thermometer avoiding parallax error.

5.8 In case if temperature and relative humidity observed is above or below specified

limit mentioned in Annexure-1, stop the activity in respective area immediately and

inform the concern head, Engineering Department for necessary rectification

and also inform to Head QA or his / her designee.

5.9 In the remarks column mention the reason (if any) for not entering the temperature

and relative humidity or for any abnormal reading.

6.0 Forms and Records

6.1 Temperature & Relative Humidity limit for different area – Annexure-1

6.2 Environmental Monitoring Record (wet & dry) – Annexure-2

6.3 Environmental Monitoring Record (Digital) – Annexure-3

6.4 Environmental Monitoring Record (Dry) – Annexure-4

6.5 Environmental Monitoring Record – Annexure-5

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Production, Quality Assurance, Quality Control, Engineering and Warehouse.

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

- process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

-

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

sop for Verification of Weighing Balance

-

Sop for Submitting of Leave Application

sop for Accident Management Procedures

sop for Accident Management Procedures

Cleaning and colour coding of Factory Apparel (Clothes)

Job Responsibilities of Key Personnel

sop for Maintenance of Building

Destruction of Batch Production and Control Records BPCR

Procedure for Sampling of Rinse water Swab

Cleaning Validation of Equipment

Measurement and Recording of Temperature and Relative Humidity