sop for Scrap Management

1.0 Objective

To lay down a procedure for handling and transfer the scrap from various departments to the scrap yard.

2.0 Scope

This Standard Operating Procedure is applicable for handling and transfer the scrap from various

departments to the scrap yard to be followed at formulation plants of abc Pvt. Ltd.

3.0 Responsibility

3.1 Officer / Executive concerned department shall be responsible for handling and transfer of scrap to scrap yard.

3.2 Officer / Executive QA shall be responsible for verification of scrap before transfer to scrap yard.

3.3 Officer / Executive HR Department shall be responsible for verification and shall receive the scraps in scrap yard.

3.4 Concerned department head and Head QA shall be responsible for compliance this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

QA : Quality Assurance

QC : Quality Control

No. : Number

NRR : Non Recoverable Rejects

HR : Human Resource Department

5.0 Procedure

5.1 Different type of scrap is generated in the plant. This scrap shall include empty

containers, gunny bags, plastic and rubber scrap, used polythene bags / used disposable

hand gloves / shoe covers / nose masks / lint free cloth, paper waste, waste of

corrugated box, stationary / carton / label, waste of broken ware, rejected glass

bottles, rejected blister / strips, NRR generated from capsule, QC department

and general waste generated in the plant.

5.2 Empty fiber container of raw materials / plastic container / empty reagent bottles:

5.2.1 Cross mark the empty containers / plastic containers by permanent marker

pen as ‘X’. Deface the labels of empty bottles. Rinse the bottles with water.

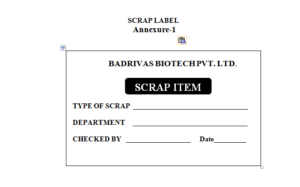

Collect them in a waste bin and label it as per Annexure-1.

5.2.2 Transfer scrap to the designated place of common scrap collection point

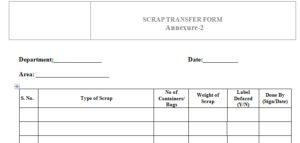

after recording the details in scrap transfer form (Annexure-2).

5.3 Empty Gunny Bags: Empty gunny bags of raw material are counted by warehouse and

the details are recorded in scrap transfer form and send to scrap collection point.

5.4 Plastic scrap / rubber scrap / used polythene bags / used disposable hand gloves / shoe covers / nose masks / lint free cloth:

5.4.1 Collect the scrap mentioned above in a polythene bag.

5.4.2 Affix the label after recording the details (Annexure-1).

5.4.3 Enter the details in scrap transfer (Annexure-2).

5.4.4 Transfer the bags to common scrap collection point.

5.5 Corrugated box / paper waste / stationary / carton waste into several parts and collect in a polythene bag.

5.5.1 Tear the waste / rejected corrugated boxes, paper waste into several parts and collect in a polythene bag.

5.5.2 Affix the label and record the details in scrap transfer note.

5.5.3 Transfer the bags to common scrap collection point.

5.6 Broken glass bottles

5.6.1 Collect the scrap containing broken glass of bottles from production area take out wash

with water and allow the water to drain by flushing after neutralization in designated area.

5.6.2 Collect it in a polythene bag. Affix the label and record its details in scrap transfer form.

5.6.3 Transfer the bag to common scrap collection point.

5.7 Rejected empty strips / blister

5.7.1 Collect the empty blister / strip, pieces of foils in a polythene bag after the defoiling procedure.

5.7.2 Affix the status label as per Annexure-1 on the bag and enter the details in scrap transfer

form (Annexure-2) and send to scrap collection point.

5.8 Non recoverable rejects generated from tablet and capsule department

5.8.1 Waste generated during in-process or in filling, sealing and packing operation, shall be

treated by taking out its liquid from filled bottle in a separate container and discard through Destruction Form.

5.8.2 Bottles and ROPP Caps shall be discarded through Scrap Form affixed with Scrap label.

5.9 Non-recoverable rejects generated from QC laboratories

5.9.1 First deface or destroy the label on sample poly bag after testing of capsules, raw material taken for

observation or conducting physical test in QC are treated as NRR are soaked in water in a plastic container.

5.9.2 Liquid waste like solution taken for analysis shall drained in sink by flushing with water.

5.9.3 Collect broken glassware & empty reagent bottles in a polythene bag. Affix the label after recording

the details. Enter the details in scrap transfer form and transfer them to scrap yard.

5.9.4 General waste generated in the plant

5.9.5 Collect all the general waste & segregate all the items like old slippers, torn booties, waste of lint free

cloth in a polythene bag. Transfer these bags to the scrap yard after recording the details

5.10 Scrap containing expired chemicals / reagent / solvent

5.11 After all the scrap is transferred to the scrap collection point, the responsible person in this area shall

check the scrap for following

5.11.1 All the Containers / Bottles / Labels shall be defaced.

5.11.2 No product or usable printed packaging (coated & uncoated) material is in scrap.

5.11.3 Segregate the bags containing scrap received as per the nature of the material as mentioned below

5.11.3.1 Glass

5.11.3.2 Plastic

5.11.3.3 Foil

5.11.3.4 Papers and others

5.11.3.5 Rejected strip / blister

5.12 After complete verification of the scrap, the person from Personnel & Administration

Department (HR) weighs the above segregated scrap and records its weight in Scrap Transfer Form.

5.13 Transfer the scrap from the collection point to common Scrap Yard and keep it till its disposal.

5.14 The scrap containing empty Blister / Strip shall be Shredded by means of Shredder / Crushing

Machine and filled in the bag and placed at designated place till its disposal.

5.15 Annexure -2 is the duplicate logbook one copy is HR department and second copy is initiator department.

5.16 Incase any filled Bottle / Strip / Blister / Coated / Uncoated / Printed Label found in scrap,

Scrap Yard person shall immediately inform to concern person / HR Department / QA Department.

6.0 Forms and Records

6.1 Scrap Label – Annexure-1

6.2 Scrap Transfer Form – Annexure-2

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Quality Assurance, Quality Control, Production

Warehouse, Personnel & Administration.

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

- process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

-

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

sop for Verification of Weighing Balance

-

Sop for Submitting of Leave Application

sop for Accident Management Procedures

sop for Accident Management Procedures

Cleaning and colour coding of Factory Apparel (Clothes)

Job Responsibilities of Key Personnel

sop for Maintenance of Building

Destruction of Batch Production and Control Records BPCR

Procedure for Sampling of Rinse water Swab

Cleaning Validation of Equipment

Measurement and Recording of Temperature and Relative Humid

Sampling of Product at Intermediate Stages

Approval of Overprinting on Packing Material

sop for Procedure for Reprocessing

Preparation and Control of Master Batch Production and Control record

Issuance and Retrieval of Control documents

Calibration Policy for equipment

procedure for batch numbering system for products

sop for Handling of Incident during operation

Procedure for Allocation of Numbers for Machine Equipment

Validation and Qualification Facility System and Equipment

In-process Checks During Packing Operation

Operation and Calibration of Leak Test Apparatus

Operation and Calibration of Friability Tester