Allocation of Room Number

1.0 Objective

1.1 To lay down a procedure for allocation of room numbers.

2.0 Scope

2.1 This Standard Operating Procedure is applicable for allocation of room numbers in Production,

Warehouse, Engineering, Personnel & Administration, Quality Control, Quality Assurance & other

departments to be followed at formulation plants of abc Pvt. Ltd.

3.0 Responsibility

3.1 Officer / Executive of concern department shall be responsible for preparation of requisition for allotment of room number.

3.2 QA Officer / Executive shall be responsible for allocation of room numbers.

3.3 Concern department Head / Head QA / his designee shall be responsible for compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

QA : Quality Assurance

QC : Quality Control

PT/PC : Production Tablet and Capsules

PL : Production Liquid

P&A : Personnel & Administration

IT : Information & Technology

ER : Engineering

WH : Warehouse

No. : Number

ID : Identification

5.0 Procedure

5.1 Each room shall have unique identification number. Once a number is allocated to any room,

the same identification number shall not be repeated to any other room of block in plant.

5.2 There shall be six digits alpha numerical numbering system for Production Tablet and capsule block,

Production Liquid block, Production Dry powder injection block, Engineering and utility block,

Personnel & Administration block and seven digits alpha numerical numbering system for

Quality Control and Quality Assurance in plant.

5.3 For example; room number of TAC ground floor shall be given as GT/000

Where, First alpha characters ‘G’ indicate the name of the floor.

Second alpha characters ‘T’ indicate the name of the block.

Third character ‘/’ shall be used as separator.

Last three numeric digits ‘000’ indicate the number sequentially.

5.4 The room number of following departments shall have room ID as shown below

5.4.1 Production Tablet and Capsule block (TAC) – T/000

5.4.2 Production Liquid block (L & L) – L/000

5.4.3 Production External block (E & E) – E/000

5.4.4 Engineering and Utility block – E/000

5.4.5 Personnel & Administration block – P/000

5.4.6 Information & Technology – IT/000

5.4.7 Quality Assurance – QA/000

5.4.8 Quality Control – QC/000

5.5 The room numbers allocated to particular room number shall be referred in the document

wherever required.

5.6 For example, first room number of ground floor in Engineering block shall be numbered

as GE/001 and next room in the same department shall be numbered as GE/002.

5.7 Departments with three storied floor i.e. Liquid & TAC ,where

Ground floor shall be given as ‘G’

First floor shall be given as ‘F’

Second floor shall be given as ‘S’

Third floor shall be given as ‘T’

5.8 For example: In TAC Block

Room present at Ground shall be designated as ‘GT/001’

Room present at First Floor shall be designated as ‘FT/001’

Room present at Second Floor shall be designated as ‘ST/001’

Room present at Third Floor shall be designated as ‘TT/001’

5.9 For all the Engineering with Utility services shall be assigned as GE/001 for

ground floor or respective floor.

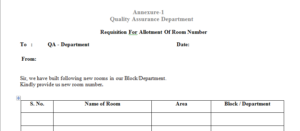

5.10 Requisition for allotment of room numbers shall be prepared by user department and

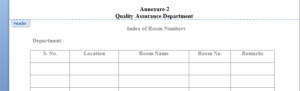

index of room shall be given by QA department and approved by Manager QA as per Annexure-1 & Annexure-2.

5.11 List shall be updated in every six months if there is any addition or deletion of room from the list.

5.12 User department shall affix the allocated number to the room to visualize in front of the particular room.

5.13 After affixing the number, executive and above of user department shall sign in the intimation

slip and the same shall be verified by executive and above of QA department.

5.14 Procedure for allocation of number of new room

5.14.1 User department shall send the intimation slip in duplicate to QA department for

allocation of room number as per the Annexure-1.

5.14.2 After receiving the intimation slip, QA department shall verify and allocate

the room number, and record in the Annexure-2.

5.14.3 Manager QA shall check the room number and same shall be intimated to

the user department for affixing the label.

5.14.4 User department will affix the label of room number to the required

room and QA will cross verify the same.

6.0 Forms and Records

6.1 Requisition for Allotment of Room Number – Annexure-1

6.2 Index of Room Numbers – Annexure-2

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Quality Assurance, Engineering

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

- process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

-

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

sop for Verification of Weighing Balance

-

Sop for Submitting of Leave Application

sop for Accident Management Procedures

sop for Accident Management Procedures

Cleaning and colour coding of Factory Apparel (Clothes)

Job Responsibilities of Key Personnel

sop for Maintenance of Building

Destruction of Batch Production and Control Records BPCR

Procedure for Sampling of Rinse water Swab

Cleaning Validation of Equipment

Measurement and Recording of Temperature and Relative Humid

Sampling of Product at Intermediate Stages

Approval of Overprinting on Packing Material

sop for Procedure for Reprocessing

Preparation and Control of Master Batch Production and Control record

Issuance and Retrieval of Control documents

Calibration Policy for equipment

procedure for batch numbering system for products

sop for Handling of Incident during operation

Procedure for Allocation of Numbers for Machine Equipment

Validation and Qualification Facility System and Equipment