Cleaning Procedure of Factory Footwear

1.0 Objective

To lay down the procedure for cleaning factory footwear.

2.0 Scope

This standard operating procedure is applicable to cleaning of factory footwear in the plant at abc company.

3.0 Responsibility

3.1 All Supervisor of HR & Administration

3.2 Manager/ Head Concern Area

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

HR : Human Resource

CC NO : Change Control Number

cGMP : Current Good Manufacturing Practice

HOD : Head of Department

5.0 Procedure

5.1 One personnel from Housekeeping department shall be delegated the for cleaning

the factory footwear of staff and workers.

5.2 Footwear shall be kept in change room at the end of each shift or whenever required.

5.3 Fix each footwear of one pair into the other footwear to prevent the mix up of different size of footwear.

5.4 Collect the footwear and take them to the assigned washing area.

5.5 Take one pair of the footwear, separate them and clean each footwear under running potable water.

5.6 Scrub the footwear using a nylon brush with soap solution (mix 20 ml of Teepol into 10 Liters of water), if required.

5.7 Again wash the footwear with potable water to remove soap solution.

5.8 Drain the excess water from the footwear and fix them into each other and place them in a clean dry plastic tub.

5.9 The plastic tub containing the clean footwear shall then be taken into the change room and the

clean footwear shall be kept in the shoe/footwear rack provided after the swing over bench.

5.10 All workmen, if to wash their footwear, shall clean their shoes as per the procedure mentioned from 5.5 to 5.8

5.11 Cleaning activities shall be recorded in to Log Book for cleaning of Factory footwear

6.0 Forms and Records

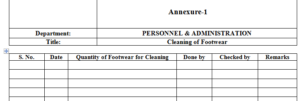

6.1 Cleaning of Factory Footwear – Annexure-1

7.0 Distribution

7.1 Master Copy – Documentation Cell (Quality Assurance)

7.2 Controlled Copy – Quality Assurance, Personnel & Administration, Production

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

- process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

-

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

sop for Verification of Weighing Balance

-

Sop for Submitting of Leave Application

sop for Accident Management Procedures

sop for Accident Management Procedures

Cleaning and colour coding of Factory Apparel (Clothes)

Job Responsibilities of Key Personnel

sop for Maintenance of Building

Cleaning Procedure of Factory Footwear