Operation and Calibration of Leak Test Apparatus

1.0 Objective

To lay down a procedure for cleaning, operation and calibration of leak test apparatus.

2.0 Scope

This Standard Operating Procedure is applicable for cleaning, operation and calibration

of leak test apparatus to be followed at formulation plants of abc Pvt. Ltd.

3.0 Responsibility

3.1 Officer/ Executive production shall be responsible for operation of leak test apparatus.

3.2 Officer/Executive QA shall be responsible for cleaning, operation and verification of leak test apparatus.

3.3 Head QA / his designee shall be responsible for compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

QA : Quality Assurance

QC : Quality Control

No. : Number

5.0 Procedure

5.1 Cleaning procedure

5.1.1 Switch off the main electrical supply.

5.1.2 Remove the vacuum pipe of Leak Test apparatus.

5.1.3 Remove the lid and perforated disc.

5.1.4 Drain the water of holding chamber.

5.1.5 Clean the acrylic lid, perforated disc and holding chamber with portable water.

5.1.6 Dry the acrylic lid, perforated disc and holding chamber with dry clean cloth.

5.1.7 Re-fix the acrylic lid, perforated disc and holding chamber to Leak Test apparatus.

5.1.8 Clean the external surface of Leak Test apparatus with dry clean cloth.

* Note-Drain the water from the sample holding chamber at the end of the shift or

days end and keep apparatus clean and dry.

5.2 Procedure for Operation of Leak Test apparatus for tablets, capsules and lozenges.

5.2.1 Check and ensure the cleanliness of Leak Test apparatus.

5.2.2 Fill the sample holding chamber of apparatus with purified water approx 2/3 volume.

Put one or two drops of Methylene blue solution if required.

5.2.3 Collect the sealed strips/blisters quantity as equal No. of sealing roller.

5.2.4 Place the collected strips/blisters in the chamber containing the purified water.

5.2.5 Place the perforated disc (plate) on the strips/blisters to avoid floating.

5.2.6 Close the chamber with lid of Leak Test apparatus and close the vent knob.

5.2.7 Open the vacuum knob and switch ‘ON’ the vacuum pump and apply the

vacuum up to 380 mm of Hg and hold for 3 minutes.

5.2.8 Check and ensure that the release valve of the apparatus should be

closed at the time of apply of vacuum.

5.2.9 After completion of 3 minutes, Switch ‘OFF’ the vacuum pump.

5.2.10 Release the vacuum slowly by opening the release valve.

5.2.11 Remove the strips/blisters from the chamber, and dry with dry clean cloth.

5.2.12 Defoil the strips/blisters and check visually for the presence of water / colo r inside the strips /blisters.

5.2.13 There should not be any traces of blue stain / water on tablet / lozenges sample.

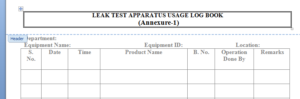

5.2.14 Records the entry in the leak test apparatus log book as in Annexure-1.

5.2.15 If there is a leak test failure, re sample and retest if further failure occurs stop

operation and intimate immediately to Officer/ Executive production.

5.2.16 Officer/ Executive production shall be investigate the matter and take the corrective action.

5.2.17 After taking corrective action withdraw fresh sample and perform the Leak Test procedure.

5.2.18 Continue the packing if no leak observed and record the results of testing in BPCR.

5.3 Procedure for Operation of Leak Test of Dry powder injections.

5.3.1 Check and ensure the cleanliness of Leak Test apparatus.

5.3.2 Fill the sample holding chamber of apparatus with purified water approx. 2/3 volume.

Put one or two drops of Methylene blue solution if required.

5.3.3 Collect the 8 vials from all 8 sealing heads and mark the bottles/vials head wise.

5.3.4 Place the collected vial in the chamber of apparatus containing the purified water with dye solution.

5.3.5 Place the perforated disc (plate) on the vial to avoid floating.

5.3.6 Close the chamber with lid and follow the procedure as 5.2.6 to 5.2.10.

5.3.7 Remove the vials from the chamber, and dry with clean cloth.

5.3.8 Check visually for the presence of water / color inside the vials.

5.3.9 There should not be any traces of blue stain / water inside the vials and further follow

the procedure as in the point from 5.2.14 to 5.2.18.

5.4 Procedure for Operation of Leak Test in liquid orals.

5.4.1 Check and ensure the cleanliness of Leak Test apparatus.

5.4.2 Collect the 8 bottles from all 8 sealing heads and mark the bottles head wise.

5.4.3 Cover the bottle necks by butter paper and tight it with rubber band.

5.4.4 Place the collected bottles in the leak test apparatus chamber.

5.4.5 Close the chamber with lid and follow the procedure as 5.2.6 to5.2.10.

5.4.6 Remove the bottles from the chamber, and uncover the butter paper from the neck of the bottles.

5.4.7 Observed the leakage of the bottles and further follow the procedure as 5.2.14 to 5.2.18.

5.5 Calibration procedure

5.5.1 Calibration of the instrument (Pressure gauge) shall be performed by outside party as per frequency.

5.5.2 Calibration certificate for the same shall be provided by them.

5.5.3 Calibration frequency: Once in a year + 30 days.

6.0 Forms and Records

6.1 Leak Test Apparatus Log Book – Annexure-1

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Quality Assurance, Production

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

- process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

-

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

sop for Verification of Weighing Balance

-

Sop for Submitting of Leave Application

sop for Accident Management Procedures

sop for Accident Management Procedures

Cleaning and colour coding of Factory Apparel (Clothes)

Job Responsibilities of Key Personnel

sop for Maintenance of Building

Destruction of Batch Production and Control Records BPCR

Procedure for Sampling of Rinse water Swab

Cleaning Validation of Equipment

Measurement and Recording of Temperature and Relative Humid

Sampling of Product at Intermediate Stages

Approval of Overprinting on Packing Material

sop for Procedure for Reprocessing

Preparation and Control of Master Batch Production and Control record

Issuance and Retrieval of Control documents

Calibration Policy for equipment

procedure for batch numbering system for products

sop for Handling of Incident during operation

Procedure for Allocation of Numbers for Machine Equipment

Validation and Qualification Facility System and Equipment