Procedure for Issuance of Extra Raw Material Packing Material

1.0 Objective

To lay down a procedure for issuance of extra raw material / packing material.

2.0 Scope

This Standard Operating Procedure is applicable for issuance of extra raw material / packing

material to be followed at formulation plant of abc Pvt. Ltd.

3.0 Responsibility

3.1 Officer/Executive Production shall be responsible to check and ensure the material as per issuance sheet.

3.2 Officer/Executive In-process Quality Assurance shall be responsible for verification of dispensed materials.

3.3 Officer/Executive/Manager Stores shall be responsible for dispensing of Excess materials as per the request of batch.

3.4 Concern department head shall be responsible for implementation of this SOP.

3.5 Head QA shall be responsible for compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

QA : Quality Assurance

No. : Number

5.0 Procedure

5.1 If in case extra raw / packing material is required to complete the batch

following steps should be followed.

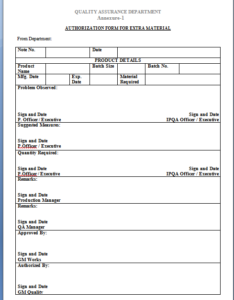

5.1.1 Officer / Executive of concern department shall fill and sign the “Authorization

form for extra material” (Annexure–1) describing the problem observed.

5.1.2 Officer / Executive QA shall verify the Authorization form for extra material and shall

sign the same, if found satisfactory using green pen.

5.1.3 Officer / Executive of concern department shall write the suggested measure along with sign and date.

5.1.4 Officer / Executive of concern department shall calculate the quantity of Excess

material (raw / packing) required as per standard given in BPCR.

5.1.5 Officer / Executive of concern department shall sign the Quantity required.

5.1.6 Officer / Executive QA shall verify the Quantity required.

5.1.7 Manager of concerned department shall give remarks with sign and date.

5.1.8 Authorization form for extra raw / packing material shall be approved by GM Works.

5.1.9 Authorization form for extra raw / packing material shall be authorized by Head Quality.

5.1.10 Completely filled Authorization form for extra material shall be then send to

QA documentation cell for record.

5.1.11 Original copy shall be submitted to documentation cell and two photocopies of the

same shall be send to concern department and Stores respectively.

5.1.12 Each Authorization form shall be assigned a number in ten alphanumeric characters

by the Quality Assurance in the format XXX/YY/ZZZ where,

XXX : ERM or EPM (ERM for extra Raw material and EPM for Extra Packing material)

/ : for a Slash

YY : for last two characters of the current calendar year e.g. 12

for year 2012.

/ : for a slash

ZZZ : for Serial No. of the Authorization form starting from 001,

002, … … up to 999.

Thus, the first Authorization form for raw material in the year 2012 shall be numbered as ERM/12/001

And, the first Authorization form for packing material in the year 2012 shall be numbered as EPM/12/001

A new series of number shall start at beginning of every calendar year.

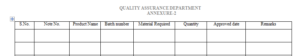

5.1.13 All Authorization form for Extra material shall be recorded by Quality Assurance

department in logbook titled Log book of Authorization form for Extra material as per Annexure-2.

5.1.14 Production shall then send requisition form to the warehouse Department for

issuance of authorized Extra Raw / Packing material.

5.1.15 Warehouse shall issue the material as per the authorization form.

5.1.16 Production shall check the Extra Raw / Packing material by weight

or Number or as per Authorization form.

5.1.17 Transfer the Dispensed Excess Raw / Packing material to the Manufacturing / Packing area.

5.1.18 Attach the duplicate copy of ‘Excess Material Requisition Form’ to the BPCR.

5.1.19 In case of excess packing material issued at the time of batch dispensing and

that excess quantity is required to get utilized for the completion of the operation

against the packing BOM. The same requisite quantity shall be issued/ reconcile by authorization form only.

6.0 Forms and Records

6.1 Authorization form for extra material – Annexure -1

6.2 Log Book of Authorization form for extra material – Annexure -2

7.0 Distribution

7.1 Master Copy – Documentation Cell (Quality Assurance)

7.2 Controlled Copy – Production department , Store

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

- process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

-

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

sop for Verification of Weighing Balance

-

Sop for Submitting of Leave Application

sop for Accident Management Procedures

sop for Accident Management Procedures

Cleaning and colour coding of Factory Apparel (Clothes)

Job Responsibilities of Key Personnel

sop for Maintenance of Building

Destruction of Batch Production and Control Records BPCR

Procedure for Sampling of Rinse water Swab

Cleaning Validation of Equipment

Measurement and Recording of Temperature and Relative Humid

Sampling of Product at Intermediate Stages

Approval of Overprinting on Packing Material

sop for Procedure for Reprocessing

Preparation and Control of Master Batch Production and Control record

Issuance and Retrieval of Control documents

Calibration Policy for equipment

procedure for batch numbering system for products

sop for Handling of Incident during operation

Procedure for Allocation of Numbers for Machine Equipment

Validation and Qualification Facility System and Equipment

In-process Checks During Packing Operation

Procedure for Issuance of Extra Raw Material Packing Material