Sampling of Product at Intermediate Stages

Objective

To lay down a procedure for sampling of product at different intermediate stages of all production areas.

2.0 Scope

This Standard Operating Procedure is applicable for in process sampling of tablet, capsule, liquid,

external to be followed at formulation plant of abc Pvt. Ltd.

3.0 Responsibility

3.1 Production Officer / Executive shall be responsible for giving intimation to QA after completion

of manufacturing process.

3.2 Officer / Executive QA shall be responsible for sampling as per intimation received from

production and submission of samples to the quality control department.

3.3 Head / In charge Quality assurance or his/ her designee shall be responsible for compliance of SOP

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

QA : Quality Assurance

No. : Number

Composite Sample : Sample collected from various identified locations within a lot or batch,

or from various phases of process and then pool the sample to represent the sample of whole batch or lot.

LAF : Laminar Air Flow

BPCR : Batch Production and Control Record.

5.0 Procedure

5.1 After completion of manufacturing process, production Officer / Executive shall fill

the “Analysis request cum report for in process / finished product” as per annexure-1and

intimate the QA Officer / Executive for sampling as per intimation.

5.2 “Analysis request cum report for in process / finished product” contains three copies of

intimation slip having the following details for distribution.

5.2.1 Pink color – BPCR Copy

5.2.2 Yellow color – QC Copy

5.2.3 White color – Production Copy

5.3 QA Officer / Executive shall verify the filled BPCR up to the manufacturing process

and if found satisfactory then only go for sampling. If any discrepancy found in filled

BPCR then same shall be rectified by production before sampling.

5.4 QA Officer / Executive shall use the clean, dry sampling devices such as spatula, spoons,

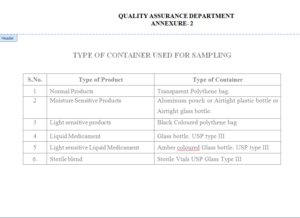

sampling rod, self sealing polybags, vials and glass bottles for sampling as per nature of product shown in annexure- 2.

5.5 QA Officer / Executive shall prepare the in process label as per annexure -3 and affix on the sampling container or bags.

5.6 Before sampling QA Officer / Executive shall check and verify the manufacturing area,

status label of area, status label of product and container as per BPCR.

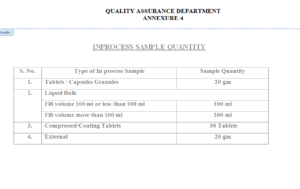

5.7 QA Officer / Executive shall withdraw the sample as per quantity mentioned in annexure-4.

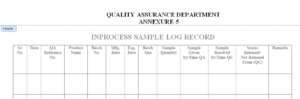

5.8 After collection of sample, QA Officer / Executive shall enter the sample details in

“In process sample analysis record” as per annexure-5 and give the QA reference no. to the sample.

5.9 After completion of documentation QA Officer / Executive shall send the sample

with intimation to QC for analysis.

5.10 QC Officer / Executive shall receive the sample and sign in the “In process sample

analysis record” as a token of receipt of sample.

5.11 After receiving result from QC, QA Officer / Executive shall attach the BPCR copy of

slip into the BPCR and allow the process to proceed further.

5.12 In-Process sampling procedure for tablet / capsule

5.12.1 QA Officer / Executive shall collect the required quantity of sample from bin

with the help of sampling rod and make a composite sample.

5.12.2 Incase of validation batch, QA Officer / Executive shall collect the sample

as per product specific validation protocol.

5.12.3 After sampling, close the lid of bin and affix the in process sample label on container / bags.

5.12.4 After sampling QA Officer / Executive shall enter the sampling details in BPCR

5.13 In-process sampling procedure for liquid bulk

5.13.1 Stir the bulk for at least 05 minutes before taking the sample to make the bulk homogenous.

5.13.2 QA Officer / Executive shall collect the sample of bulk from manufacturing tank with

the help of liquid sampler and make a composite sample.

5.13.3 In case of validation batch, sample shall be collected as per product specific validation protocol.

5.13.4 After sampling, close the lid of tank and affix the in process sample label on the sampling bottle.

5.13.5 After sampling QA Officer / Executive shall enter the sampling details in BPCR

5.13.6 In case of validation batch, collect the sample as per specific product validation protocol.

5.13.7 After sampling, close the lid of blender and affix the “in process sample label” on the vials.

5.13.8 After sampling QA Officer / Executive shall enter the sampling details in BPCR

5.14 In-process sampling procedure for liquid bulk

5.14.1 Stir the bulk for at least 05 minutes before taking the sample to make the bulk homogenous.

5.14.2 QA Officer / Executive shall collect the sample of bulk from manufacturing tank with the help

of liquid sampler and make a composite sample.

5.14.3 In case of validation batch, sample shall be collected as per product specific validation protocol.

5.14.4 After sampling, close the lid of tank and affix the in process sample label on the sampling bottle.

5.14.5 After sampling QA Officer / Executive shall enter the sampling details in BPCR

5.14.6 In case of validation batch, collect the sample as per specific product validation protocol.

5.14.7 After sampling, close the lid of blender and affix the “in process sample label” on the vials.

5.14.8 After sampling QA Officer / Executive shall enter the sampling details in BPCR

6.0 Forms and Records

6.1 Analysis request cum report for in process / Finished product – Annexure- 1

6.2 Types of containers used for sampling – Annexure- 2

6.3 In process sample label – Annexure- 3

6.4 In process sample quantity – Annexure- 4

6.5 In process sample log record – Annexure- 5

7.0 Distribution

7.1 Master Copy – Documentation Cell (Quality Assurance)

7.2 Controlled Copy – Quality Assurance, Production

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

- process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

-

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

sop for Verification of Weighing Balance

-

Sop for Submitting of Leave Application

sop for Accident Management Procedures

sop for Accident Management Procedures

Cleaning and colour coding of Factory Apparel (Clothes)

Job Responsibilities of Key Personnel

sop for Maintenance of Building

Destruction of Batch Production and Control Records BPCR

Procedure for Sampling of Rinse water Swab

Cleaning Validation of Equipment