sop for Dispensing of Raw Material

1.0 Objective

To lay down a procedure for dispensing of raw material.

2.0 Scope

This Standard Operating Procedure is applicable for dispensing of raw material to be followed at formulation plants of A B C Company.

3.0 Responsibility

3.1 Officer / Executive warehouse shall be responsible for dispensing of raw material.

3.2 Head Warehouse is responsible for ensuring the compliance of the SOP.

3.3 Head QA or his designee shall be responsible for implementation and compliance this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

i.e. : That is

No : Number

w.r.t : With respect to

B. No. : Batch Number

BPCR : Batch Production and Control Record

FIFO : First in first out

WH : Warehouse

HOD : Head of Department

5.0 Procedure

5.1 Precautions:

5.1.1 Ensure that cleaning status as “CLEANED” is displayed on status board of Dispensing Area.

5.1.2 Ensure the entire area i.e. ceiling, risers, RLAF, weighing balance, dispensing aids, dispensing aids trolley, floor,

walls and windows are clean and dry.

5.1.3 Ensure that the waste-bin is empty and clean.

5.1.4 Ensure the area temperature; relative humidity and pressure difference are in acceptable limits.

5.1.5 Ensure the weighing balance is clean, dry and calibrated. The weighing balance is verified and readings are noted down/recorded & checked.

5.1.6 Ensue that RLAF is started 30 minutes before dispensing.

5.1.7 The material container shall be brought into the RLAF in ‘safe zone’ marked by ‘Red Line’.

5.1.8 Loose containers of the raw materials shall be taken first.

5.1.9 One batch of given product shall be dispensed at a time.

5.1.10 Dispensing must be carried out in presence of IPQA person.

5.1.11 First dispense excipients, then Active and in last dispense the colors.

5.2 Procedure For Dispensing of Raw Materials:

5.2.1 The production department shall send the “Batch Production & Control Record” (BPCR) of batch to Warehouse for

dispensing of Materials.

5.2.2 Warehouse Officer / Executive shall check the Product Name, B. No. & Batch Size on BPCR, given by production department.

5.2.3 Visually check the availability of the released raw materials as per the item code numbers given in BPCR. If there is any shortage of material, the dispensing operation shall be not start.

5.2.4 Warehouse Officer / Executive shall dispense the material as per BPCR.

5.2.5 Take the materials mentioned in BPCR from their respective storage area on the pallet and transfer these approved materials container to the dispensing area through “Material Entry”.

5.2.6 Approved container shall be checked for following details:

5.2.6.1 Name of material.

5.2.6.2 Item code number.

5.2.6.3 A.R. No.

5.2.6.4 GRN No.

5.2.6.5 Retest date.

5.2.6.6 Pharmacopoeia Status (IP/BP/USP)

5.2.7 The warehouse personnel shall ensure that the material is transferred for dispensing based on FIFO basis. Only QC approved material shall be transferred for dispensing.

5.2.8 Before starting dispensing activity ensure to lock in staging area.

5.2.9 Warehouse personnel shall follow the gowning procedure as per WH/004 and enter the designated area for dispensing of materials.

5.2.10 Take the Line Clearance by IPQA personnel before starting the dispensing activity.

5.2.11 All operations during dispensing must be carried out by the warehouse personnel duly checked by IPQA personnel.

5.2.12 Record the starting time on “Dispensing Booth Usage Log” as shown in Annexure-2.

5.2.13 Only one material shall be enter and dispensed in the dispensing booth and other material shall be enter and dispensed in the dispensing booth only when the first material is removed.

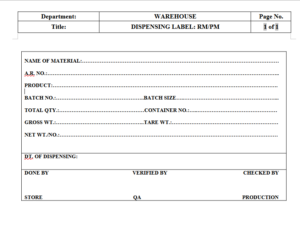

5.2.14 Record the A.R. No. in BPCR and “Dispensing Label” as shown in Annexure-1.

5.2.15 Take the weight of the LDPE bag and cable tie, tare the balance and note down in BPCR and in “Dispensing Label”.

5.2.16 Transfer the specified quantity of material using clean scoop/ spatula from the original container to LDPE bag for

dispensing.

5.2.17 Record the tare weight, net weight and gross weight in the BPCR and in “Dispensing Label”.

5.2.18 Fasten the LDPE bag with cable tie in which the material is dispensed.

5.2.19 Keep the dispensed material LDPE bag in another LDPE bag after keeping the dispensed material label in between the LDPE Bags and finally fasten the outer LDPE bag with cable tie.

5.2.20 The IPQA personnel shall verify the description of material, A.R. No., weight and sign the “Dispensing Label” and

BPCR.

5.2.21 Transfer the dispensed materials to the day store room by keeping them on a clean pallet / in process container.

5.2.22 Used scoops shall be kept in the “To be Cleaned Dispensing Tools” container and hand gloves in the waste-bin.

5.2.23 Warehouse personnel shall transfer the dispensed materials through Lift along with BPCR to Production and shall keep the store copy for records.

5.2.24 Record the completion time on “Dispensing Booth Usage Log” as shown in Annexure – 2.

5.2.25 Production personnel shall check the material and sign on the “Dispensing Label” in checked by column.

5.3 Post operation:

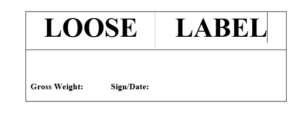

5.3.1 After dispensing of the material affix “Loose” label on the original container as per Annexure-3 and transfer it from the dispensing room to “Transformation Room”.

5.3.2 Open the lock of Transformation Room.

5.3.3 Put a label “To be Cleaned” on the Dispensing Room as per SOP No. BBL/WH/SOP/025.

Note: In case of sterile material dispense the full container to production and maintain their record.

6.0 Forms and Records

6.1 Dispensing Label RM/PM – Annexure-1

6.2 Dispensing Booth Usage Log – Annexure-2

6.3 Loose Label – Annexure-3

7.0 Distribution

7.1 Master Copy – Documentation Cell (Quality Assurance)

7.2 Controlled Copy – Warehouse Department.

8.0 History

-

Revision Number

Details For Change

Reason for Revision

00

New SOP

NA

Dispensing Label RM/PM – Annexure-1

Dispensing Booth Usage Log – Annexure-2

Loose Label – Annexure-3

- process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

sop for Dispensing of Raw Material