sop for handling of re-test materials

1.0 Objective

To lay down a procedure for handling of re-test materials.

2.0 Scope

This Standard Operating Procedure is applicable for handling of re-test materials to be followed

at formulation plants of abc company.

3.0 Responsibility

3.1 Officer/Executive warehouse shall be responsible for handling of re-test materials.

3.2 Head Warehouse is responsible for ensuring the compliance of the SOP.

3.3 Head QA or his designee shall be responsible for implementation and compliance with SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

i.e. : That is

No. : Number

w.r.t : With respect to

WH : Warehouse

HOD : Head of Department

5.0 Procedure

5.1 Handling of retesting of raw material

5.1.1 Warehouse Officer / Executive shall prepare the monthly list in the last week of every month

for all the raw materials, which are due for retesting in the next month and intimate to Quality Control Department

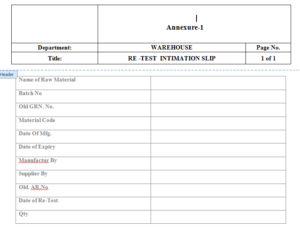

as per format No

5.1.2 Prepare intimation slips for as per format and send to QC Department.

5.1.3 Deface / cross the existing approved label for all the materials for which retesting is required.

5.1.4 Put quarantine label and transfer the material to the designated quarantine area.

5.1.5 QC shall take sample from the material and affix sample and under test label on the

container from which the sample has been taken.

5.1.6 Transfer the sampled material into the designated under test area.

5.1.7 After testing, the QC department shall paste new approved / rejected label with new A.R. No. and retest date.

5.1.8 The material shall be transferred from under test material to approved/rejected material Area.

5.2 Handling of near expiry raw materials

5.2.1 Warehouse shall give details of the material near to expiry to plant head.

5.3 Handling of expired raw materials

5.3.1 Cross the approved labels of the material.

5.3.2 Transfer expiry material in rejected area.

5.3.3 Take the permission of destruction of raw material on destruction note and get it approval

from QA and plant head and destroy the material as per suggested mode in the presence of QA and Security Personnel.

6.0 Forms and Records

6.1 Re -Test Intimation Slip – Annexure-1

7.0 Distribution

7.1 Master Copy – Documentation Cell (Quality Assurance)

7.2 Controlled Copy – Warehouse Department.

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

- process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipmentconcurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Preparation Approval Control and Distribution of Master Formula Records

calibration policy for equipment and instruments

evaluation Sampling of Raw Materials questionnaire

training evaluation questionnaire

sop for approval of Contract Parties

sop for Operation and Cleaning of Purified Water Generation System

sop for Storage of Standard Weights

sop for Dispensing of Raw Material

Receipt of Excess RM/PM from Production

sop for Dispatches of Finished Goods

Cleaning of Dispensing and Sampling Area

procedure for cleaning of dispensing tools

Cleaning and Operation of Reverse Laminar Air Flow

Handling of Open-Damaged Containers in Warehouse

sop for Discard of Scrap From Warehouse

Cleaning and Operation of Reverse Laminar Air Flow

sop for Cleaning of High Racks

sop for Issuance of Excess RM/PM to Production

sop for Cleaning of MS Shutter

procedure for handling of rejected materials