SOP for Materials Entry Through Main Gate

1.0 Objective

To lay down a procedure for materials entry through main gate.

2.0 Scope

This Standard Operating Procedure is applicable for materials entry through main gate to be followed at formulation plants of A B C Pvt. Ltd.

3.0 Responsibility

3.1 Officer / Executive warehouse / Security Officer shall be responsible for the materials entry through main gate.

3.2 Head Warehouse is responsible for implementation of this SOP.

3.3 Head QA / his designee shall be responsible for compliance this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

i.e : That is

No. : Number

WH : Warehouse

5.0 Procedure

5.1 Material Entry:

5.1.1 On arrival of vehicle at security gate the security personnel shall check the consignee name in the

Delivery Challan, L.R. Copy and Form-31 and allow the vehicle to enter into the factory premises.

5.1.2 Security personnel shall make the necessary entry in to the inward register and put gate entry

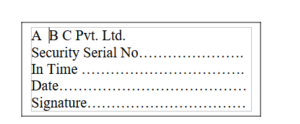

stamp on the delivery documents with the below mentioned stamp.

5.1.3 Securities personnel shall inform to Warehouse Officer/Executive.

5.1.4 Warehouse Officer/Executive bring the Challan/Invoice to warehouse for verification and

Warehouse person shall verify purchase order no., approved vendor name from approved vendor list.

In case of any discrepancy in documentation, the matter shall be convey in the QA Department And Purchase Department.

5.1.5 The security person shall send the vehicle to respective block unloading bay to unload the material.

6.0 Forms and Records

6.1 None.

7.0 Distribution

7.1 Master Copy – Documentation Cell (Quality Assurance)

7.2 Controlled Copy – Warehouse Department

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for cleaning of dust exhausts

entry and exit Procedure of employees to company premises

SOP for Materials Entry Through Main Gate