Analysis of Nystatin ointment 100000 Units per gram

1.0 OBJECTIVE

1.1 To lay down a procedure for Analysis of Nystatin Ointment.

2.0 SCOPE

2.1 This procedure is applicable to the analysis of Nystatin Ointment.in Quality control laboratories

3.0 RESPONSIBILITY

3.1 Q.C- Chemist

4.0 ACCOUNTABILITY

4.1 Manager-Quality Assurance

5.0 PROCEDURE

5.1 Description: Pour 50ml finish sample in beaker and observed visually.

5.2 Average fill weight: Weigh accurately bulk of 20 tube and calculate the average fill weight.

Average fill Weight = fill weight of 20 tube/20.

5.3 pH: Weight accurately 5.0 gm sample dissolve in 100 ml off distilled water and observed the pH

5.4 Water: Not more than 0.5%, 20 ml of a mixture of toluene and methanol (7:3) being used in

place of methanol in the titration vessel.

6.0 ASSAY:

Composition:

Nystatin 100000 units per gram. Method of Nystatin: Antibiotic assay

Media Preparation

Take clean a conical flask weigh the quantity of selected media and Polysorbate 80 as per label claim

but according to the need of volume of media to be employed for testing. Dissolve the media in distill

water completely with gently warming. Adjust the pH of media as it is required. Then get it autoclaved at 1210 C for 15 minutes.

Test Preparation

(A) Prepare freshly standard solution and is serial dilution. Weigh accurately the quantity of working

reference substance and dissolve in required Dimethylformamide in a volumetric flask and make the

volume of solution with B6 buffer as per required concentration.

100000-unit eq. wt. in mg →100 ml (A) Dimethylformamide

5ml of A→50 ml(B) B6 Buffer

10 ml of B→25 ml (Standard High) B6 Buffer

10 ml of B→100ml (Standard Low) B6 Buffer

(B) Preparation of test solution: – Weigh accurately the weight of substance being examined which concentration

is equal to std dissolve in Dimethylformamide in the same manner as stated in preparation of standard, prepare

serial dilution with B6 buffer of the same which concentration shall be parallel to the at a standard serial dilution.

Eq. To 100000 units→100 ml (A) Dimethylformamide

5 ml of A→50 ml(B) B6 Buffer

10 ml of B→25 ml (Test High) B6 Buffer

10 ml of B →100ml (Test Low) B6 Buffer

7.0 Requirements

Sterile borer, micropipette with tips, normal saline (0.9%), Polysorbate 80, Antibiotic assay medium, Autoclave,

LAF, Incubator, Antibiotic zone reader,90 mm Petri plates test tubes and test organism

(Saccharomyces cerevisiae ATCC NO.-2601).

8.0 Test procedure

1. To ensure that area is cleaned and sterile.

2. To check the environmental condition of area to be employed for testing like temperature and humidity.

3. Run the LAF and AHU minimum 1 hour before start of the test.

4. Bring all necessary articles like autoclaved media, glassware, standard and test solution autoclaved crock borer,

micropipette with disposable tips in sterile area and keep them in front of LAF. Prepare spore suspension(inoculum).

Take one loop full culture strain and mix in 10 ml 0.9%Nacl sterile solution.

5. Pour this inoculum into the sterile media which temp. shall not exceed400 C and shake it clockwise

and anticlockwise for proper mixing of spore to the, media.

6. Pour exact and equal 25 ml amount of media in four Petri dishes with the help of 25 ml measuring cylinder and then leave it for solidification.

7. After solidification of media prepare cups with the help of sterile borer.

8. Prepare at least four such type media plates for one sample assay analysis.

9. Now prepare the standard and sample higher and lower dilution as per the individual respective product test procedure.

10. Mark each cavity of plates as standard higher (SH), standard lower (SL) and test higher (TH), test lower (TL).

11. Pipette about 100 micro liters of standard high and 100 micro liters of standard low dilution in opposite direction in four plates.

12. Pipette about 100 micro liters of test high and 100 micro liters of test low dilution in opposite direction in four plates.

13. After pouring of solution leave the plates on its position for minimum 1 hour in front of LAF for proper absorption of aliquot poured.

14. After one hour collect the plate and incubate in an incubator at 290 to 310 C for 48 hours.

9.0 Precaution

1. Glassware/cup borer used shall be sterilized.

2. Inside the incubator the level should be smooth and same to avoid any unwanted irregular, immeasurable inhibitions zones.

3. All equipment is to be thoroughly cleaned before and after each use.

4. Proper mix the appropriate culture in the media, to get proper zone.

5. During mixing and pouring of media take care no air bubble should be formed.

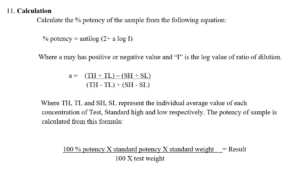

10. Estimation of potency

1. Average the diameters of the zones for each dilution and calculate the percentage potency of the sample from

the given formula mentioned in calculation.

12.0 ABBREVIATIONS

| Sr. No. | Abbreviation used | Full form of abbreviation used |

| 1.0 | SOP | Standard Operating Procedure |

| 2.0 | QA | Quality Assurance |

| 3.0 | QC | Quality Control |

| 4.0 | MB | Microbiology Lab |

| 5.0 | IPA | Iso Propyl Alcohol |

| 6.0 | μg | Micro gram |

| 7.0 | °C | Degree Centigrade |

| 8.0 | % | Percentage |

standard testing procedure flavour mixed fruit

standard testing procedure dicyclomine hydrochloride

Standard testing procedure honey pure

standard testing procedure dextromethorphan hydrobromide

standard procedure of levocarnitine injection

Analysis of Ivermectin Suspension

standard testing procedure artemether injection

standard testing procedure artemether injection

standard testing procedure Carbocisteine syrup

standard testing procedure Phytomenadione injection

standard testing procedure serratiopeptidase

standard testing procedure starch IP

standard testing procedure sucrose refined sugar

standard testing procedure titanium dioxide

standard testing procedure tramadol hydrochloride

standard testing procedure zinc sulphate

standard testing procedure croscarmellose sodium

standard testing procedure colour erythrosine supra

standard testing procedure magnesium hydroxide

standard testing procedure diclofenac sodium

standard testing procedure dibasic calcium phosphate

standard testing procedure cyanocobalamin

standard testing procedure cholecalciferol

standard testing procedure Calcium carbonate oyster shell powder

standard test procedure Calcium Citrate

standard testing procedure Bronopol