Operation and Calibration Procedure for Disintegration Test apparatus

1.0 OBJECTIVE -To lay down the procedure for operation and calibration of disintegration test

Apparatus.

2.0 SCOPE -This SOP is applicable for operation and calibration of disintegration test apparatus

3.0 RESPONSIBILITY – Execution – officer QC

Checking – Assistant Manager

4.0 ACCOUNTABILITY – Manager Quality Control

5.0 PROCEDURE

5.1 Ensure that the power supply to the apparatus is switched OFF before cleaning. Clean the

Equipment with a clean dry cloth per day. Occasionally wet cloth dipped in dilute soap solution

May be used. Precaution has to be taken to clean the equipment immediately with dry cloth to

Remove the moisture.

5.2 Clean the beaker and basket at the end of every operation.

6.0 OPERATING INSTRUCTIONS

6.1 Ensure the apparatus is properly connected to the power supply.

6.2 Switch ON the power.

6.3 Fill the beaker of DT apparatus with Purified water in sufficient quantity and adjust the

Temperature 37°C ( between 35°C to 39°C)

With Keys located on the front side of the instrument

6.4 Fix the beaker in its position and adjust the level of water so that when the basket is in upper most position,

wire mesh of the basket is 25 mm below the water level, and when it is at lower most position the wire mesh is at least 25 mm above the bottom of the beaker.

6.5 Once the set temperature is attain 37 ± 2 OC.

6.6 start the instrument and carefully watch. Observe the tablets.

6.9 In case of dispersible tablets, water temperature should be maintained within 15 to 25 OC.

6.1.1 Place on tablet / capsule in each of the tube and insert a disc in each of the tube.

6.1.2 Start the apparatus and Note the time taken by the last tablet / capsule for complete

Disintegration.

6.1.3 Switch OFF the apparatus and power supply after the test is over, clean the basket, discs and

Beaker.

7.0 CALIBRATION PROCEDURE

7.1 Start the basket – rack assembly and Timer simultaneously.

7.2 Place the standardized calibrated thermometer to record the actual temperature against the

Temperature set.

7.3 Note the temperature of water in the beaker and Oscillation per minute of the basket-rack

Assembly.

7.4 Switch OFF the apparatus and record the observations in the calibration record as per

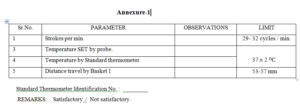

Annexure –1.

Report and discrepancy observed during calibration or operation of the instrument to Quality

Manager and notify the defect to Service Engineer to rectify the defect. Affix ‘Under

Maintenance ‘label on the instrument.

8.0 ACCEPTANCE CRITERIA

8.1 The temperature shall be between 37 ± 2 OC.

8.2 Oscillation per minute of basket rack shall be between 29 to 32 per minute.

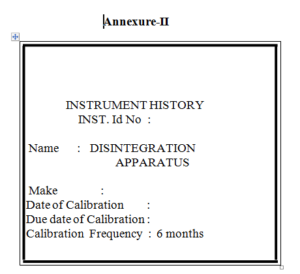

9.0 FREQUENCY OF CALIBRATION

Once in 6 month and after each maintenance job.

10.0 ABBREVIATIONS & ANNEXURES

DT = Disintegration test

sop for Calibration and Maintenance of Laboratory Instruments and Equipment

Disposal of Residual Sample or Left Over Material

sop for for Laboratory Incident

standard operating procedure temperature monitoring

sop for operation of infrared moisture balance

sop for preparation of mobile phase

sop for Preparation and Issuance of Analysis protocol standard

sop of placebo and impurity stock solutions

sop for disposal of residual sample

sop for handling of pharmacopoeial changes

sop for procedure for operation of ultrasonic cleaner

difference between UPLC and HPLC

sop for for Emergency Eyewash and Shower

sop for operation and calibration of total organic carbon analyzers

sop for operation of cobb tester

sop for Operation and calibration of atomic absorption spectrophotometer

sop for Operation and calibration of gas liquid chromatograph

sop for operation of humidity oven

sop for operation and calibration of serological water bath

sop for monitoring of drain trap

sop for destruction of analytical samples after testing and control samples

sop for destruction of used chemicals

Sop for Operation of suction pump

sop for Operation and calibration uv cabinet

sop for Operation and calibration of bulk density apparatus

sop for operation and calibration of shore hardness tester

sop for operation of rub proofness tester

sop for monitoring of purified water

sop for Retesting of packaging materials

sop for Retesting and resampling of raw materials

sop for Control of issuance of record of analysis green sheets

sop for Control of computer passwords

sop for sampling of packaging materials PM

sop for sampling of sterile raw material

sop for sampling of intermediates and finished products

sop for operation and calibration of friability test apparatus

sop for approval and rejection of packaging materials

sop for non conformance of RM PM and finished product

sop for collection storage and disposal of control samples

sop for trend analysis of finished products

sop for Chromatographic practices and system suitability

SOP For Good Laboratory Practices

sop for cleaning and operation of sieve shaker

general specification of packing material cartons

sop for Password for Analytical Instrument and LIMS software

sop for Rounding off numerical analytical results

sop for sampling of bulk and finished product

sop for cleaning of spillage material

sop for Handling of Reference Standard

sop for hplc column maintenance and washing

procedure for sampling and handling of bulk sample

STP for borewell generation point (raw water storage tank)

sop for preparation and standardization of 0.1M Zinc Sulphate

Operation &calibration of analytical balance (dhona)

Operation and Calibration Procedure for Disintegration Test apparatus

sop for preparation and standardization of 1 M Hydrochloric Acid

Preparation and standardization of 0.1 M ceric ammonium sulphate solution

sop for preparation and standardization of 0.05 m iodine solution

validation of volumetric solution 0.1m ammonium thiocyanate

handling of reference standard and preparation of working standard

sop for water sampling and analysis

sop for operation for validation of excel worksheets

sop for stability of volumetric solutions

sop for preparation of raw material in process finish product packing material data sheets

sop for handling of hazardous chemicals

sop for handling of glassware and allocation of identification number

sop for operation cleaning and calibration of bursting strength tester

sop for rounding off the analytical test results

procedure for Analyst Qualification

sop for operation and calibration of dissolution Apparatus

procedure for maintenance of desiccators

sop for for hplc column receipt checking id no and regeneration

safety data sheet for laboratory chemicals

procedure for handling of poisonous chemicals

sop for cleaning of sampling devices

sop for calibration procedure of instruments

sop for specification and standard testing raw material packing material and finished product

procedure for operation and calibration of potentiometric titrator

procedure for operating and calibration of digital hardness tester

procedure for disposal of expired chemicals, reagents and solvents

sop for behavior in quality control department

sop for preparation and standardization 0.1M sodium thiosulphate

sop for preparation and standardization 0.1M Disodium Edetate

preparation and standardization 0.1M Sodium Hydroxide Solution

Preparation and standardization of 0.1M Perchloric acid solution

sop for preparation 0.05M edetate disodium

sop for preparation 0.1M silver nitrate

sop for Operation and Calibration of High Performance Liquid Chromatography

sop for UV & Visible Spectrophotometer

procedure for Cleaning of laboratory glassware

Cleaning of Instrument, Instrument bench and surrounding area of Quality

Safety Precaution in Quality Control Department

Operation & Calibration of Analytical Balance

Calibration of Glassware in Quality Control Department

handling of samples received in Quality Control

Cleaning and Operation of Refrigerator

Operation, Cleaning and Calibration of water bath

Operation & Calibration of Refractometer

Operation and Cleaning of Centrifuge Apparatus

cleaning, operation & calibration of Vernier caliper

Calibration of Fourier Transform Infrared Spectrophotometer (FTIR)

Cleaning and operation of Moisture Analyzer

Cleaning & Operation of Vacuum pump in Quality Control Department

Operation and Calibration of Polarimeter

Cleaning and operation of Magnetic Stirrer

Cleaning Operation and Calibration of Melting Point

Operation Cleaning and Calibration of Muffle Furnance in Quality Control Department

procedure of operation and Cleaning of Sonicator

Operation Cleaning & Calibration of pH meter in Quality Control Department

Entry and Exit in Quality Control Department