sop for for hplc column receipt checking id no and regeneration

1.0 OBJECTIVE

1.1 To describe a procedure for Receipt, Checking, Id No. and Regeneration of HPLC column.

2.0 SCOPE

2.1 This procedure is applicable for Receipt, Checking, Id No. and Regeneration of HPLC column of Quality Control Department

3.0 RESPONSIBILITY

3.1 Officer /Executive – QC

4.0 ACCOUNTABILITY

4.1 Head – QC

5.0 PROCEDURE

5.1 On receipt of new column check the column received as per indent and mention details of column in Format

5.2 Ensure that the instrument is clean. Condition the column using methanol at 0.5 ml/minute for 30 minutes.

5.3 Check the column with respect to certificate of analysis for Back Pressure.

5.4 Carry out the column performance (Theoretical Plates, Tailing & Resolution) using following chromatographic condition. Record the results in Format

5.5 Performance of Reversed Phase Column

Chromatographic conditions:

Mobile phase : Methanol : water (70:30) % v/v

Flow rate : 1.0ml/min

Wavelength : 254nm

Inj. Volume : 20µl

5.6 Test solution for C8 and C18: Mixture of Benzene and Toluene (0.1%) in mobile phase.

5.7 After checking, flush the column with methanol for 30 minutes at flow rate of 0.5 ml/min. in normal direction and store the column in methanol.

5.8 Test solution for Cyano and Phenyl: Mixture of Benzene (0.1%) and Naphthalene (4mg) in 100 ml Mobile phase.

5.9 Performance of Normal Phase Column

5.10 Chromatographic conditions :-

Mobile phase : IPA : Hexane (40 : 60) v/v

Flow rate: 1.0ml/min.

Wavelength : 254nm

Inj. Volume : 20µl

Test solution: Mixture of Toluene (0.5 µl/ml) and Diethyl phthalate (2µl/ml) in mobile phase.

5.11 After checking, flush the column with Hexane for 30 min. at flow rate of 1.0ml/min and store the column in Hexane.

5.12 Enter the details of column in Format

5.13 Column Regeneration for Reverse Phase Column.

5.14 Flush the column using warm water (55ºC) at flow rate of 0.5 ml/min. for 20 minutes. Maintain the column at (55ºC) in column oven during flushing.

5.15 Inject 100 µl of DMSO four times at interval of 2 minutes.

5.16 Flush it with methanol at flow rate of 0.5 ml/min in reverse direction for 60 minutes. After flushing with methanol,

flush the column with chloroform for 60 minutes at flow rate of 0.5 ml/min in reverse direction.

5.17 At the end, wash the column in methanol for 30 minutes at flow rate of 0.5 ml/min. In reverse direction.

5.18 After regeneration of column, perform the column performance test as per Step 5.4.1.

5.19 Store the column in methanol, after flushing with methanol for 30 minutes at flow rate of 0.5 ml/min in normal direction.

5.20 Maintain the column History card on use of column during analysis as per Format

5.21 Column Regeneration for Normal Phase Column

5.22 Flush the column with Hexane for 60 minutes at flow rate of 2.0 ml/min.

5.23 After flushing with Hexane, wash the column with Methylene chloride for 60 min at flow rate of 2.0 ml/min

5.24 After flushing with methylene chloride, wash the column with Isopropyl alcohol for 60Minutes at flow rate of 2.0 ml/min.

5.25 At the end, flush the column with methanol for 60 minutes at flow rate of 2.0 ml/min.

5.26 After regeneration of column, perform the column performance test as per Step 5.4.2

5.27 Store the column in Hexane, after flushing with Hexane for 20 minutes at flow rate of 2.0ml/min in normal direction.

5.28 If the system suitability fails then only column regeneration required.

5.29 Column identification Number shall be given as for Column numbering will be: DB/QC/C/XXX

Where DB means Devbhoomi Pharmaceuticals.

QC: For Quality Control.

C: For Column.

XXX: Serial number starting from 001.

5.30

Column suitability parameters during CPT:

5.30.1 Theoretical Plates NLT 70% with respect to manufacturer COA.

5.30.2 Tailing between 0.8 to 1.5.

5.30.3 Resolution between two peaks NLT 5.

6.0 REFERENCE

6.1 In House

7.0 FORMATS

HPLC column check & regeneration record

Column Received & Identification No.

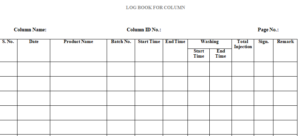

Log Book for Column

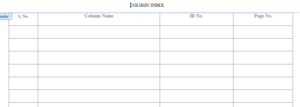

Column Index

8.0 ABBREVIATIONS

8.1 QC : Quality Control

8.2 QA : Quality Assurance

8.3 QCA : Quality Control Analytical

8.4 SOP : Standard Operating Procedure

8.5 No.: Number

8.6 Dept.: Department

8.7 min: Minute

8.8 °C : Degree Celsius

8.9 IPA: Isopropyl Alcohol

8.10 µl: Micro liter

8.11 DMSO: Dimethylsulfoxide

sop for Calibration and Maintenance of Laboratory Instruments and Equipment

Disposal of Residual Sample or Left Over Material

sop for for Laboratory Incident

standard operating procedure temperature monitoring

sop for operation of infrared moisture balance

sop for preparation of mobile phase

sop for Preparation and Issuance of Analysis protocol standard

sop of placebo and impurity stock solutions

sop for disposal of residual sample

sop for handling of pharmacopoeial changes

sop for procedure for operation of ultrasonic cleaner

difference between UPLC and HPLC

sop for for Emergency Eyewash and Shower

sop for operation and calibration of total organic carbon analyzers

sop for operation of cobb tester

sop for Operation and calibration of atomic absorption spectrophotometer

sop for Operation and calibration of gas liquid chromatograph

sop for operation of humidity oven

sop for operation and calibration of serological water bath

sop for monitoring of drain trap

sop for destruction of analytical samples after testing and control samples

sop for destruction of used chemicals

Sop for Operation of suction pump

sop for Operation and calibration uv cabinet

sop for Operation and calibration of bulk density apparatus

sop for operation and calibration of shore hardness tester

sop for operation of rub proofness tester

sop for monitoring of purified water

sop for Retesting of packaging materials

sop for Retesting and resampling of raw materials

sop for Control of issuance of record of analysis green sheets

sop for Control of computer passwords

sop for sampling of packaging materials PM

sop for sampling of sterile raw material

sop for sampling of intermediates and finished products

sop for operation and calibration of friability test apparatus

sop for approval and rejection of packaging materials

sop for non conformance of RM PM and finished product

sop for collection storage and disposal of control samples

sop for trend analysis of finished products

sop for Chromatographic practices and system suitability

SOP For Good Laboratory Practices

sop for cleaning and operation of sieve shaker

general specification of packing material cartons

sop for Password for Analytical Instrument and LIMS software

sop for Rounding off numerical analytical results

sop for sampling of bulk and finished product

sop for cleaning of spillage material

sop for Handling of Reference Standard

sop for hplc column maintenance and washing

procedure for sampling and handling of bulk sample

STP for borewell generation point (raw water storage tank)

sop for preparation and standardization of 0.1M Zinc Sulphate

Operation &calibration of analytical balance (dhona)

Operation and Calibration Procedure for Disintegration Test apparatus

sop for preparation and standardization of 1 M Hydrochloric Acid

Preparation and standardization of 0.1 M ceric ammonium sulphate solution

sop for preparation and standardization of 0.05 m iodine solution

validation of volumetric solution 0.1m ammonium thiocyanate

handling of reference standard and preparation of working standard

sop for water sampling and analysis

sop for operation for validation of excel worksheets

sop for stability of volumetric solutions

sop for preparation of raw material in process finish product packing material data sheets

sop for handling of hazardous chemicals

sop for handling of glassware and allocation of identification number

sop for operation cleaning and calibration of bursting strength tester

sop for rounding off the analytical test results

procedure for Analyst Qualification

sop for operation and calibration of dissolution Apparatus

procedure for maintenance of desiccators

sop for for hplc column receipt checking id no and regeneration

safety data sheet for laboratory chemicals

procedure for handling of poisonous chemicals

sop for cleaning of sampling devices

sop for calibration procedure of instruments

sop for specification and standard testing raw material packing material and finished product

procedure for operation and calibration of potentiometric titrator

procedure for operating and calibration of digital hardness tester

procedure for disposal of expired chemicals, reagents and solvents

sop for behavior in quality control department

sop for preparation and standardization 0.1M sodium thiosulphate

sop for preparation and standardization 0.1M Disodium Edetate

preparation and standardization 0.1M Sodium Hydroxide Solution

Preparation and standardization of 0.1M Perchloric acid solution

sop for preparation 0.05M edetate disodium

sop for preparation 0.1M silver nitrate

sop for Operation and Calibration of High Performance Liquid Chromatography

sop for UV & Visible Spectrophotometer

procedure for Cleaning of laboratory glassware

Cleaning of Instrument, Instrument bench and surrounding area of Quality

Safety Precaution in Quality Control Department

Operation & Calibration of Analytical Balance

Calibration of Glassware in Quality Control Department

handling of samples received in Quality Control

Cleaning and Operation of Refrigerator

Operation, Cleaning and Calibration of water bath

Operation & Calibration of Refractometer

Operation and Cleaning of Centrifuge Apparatus

cleaning, operation & calibration of Vernier caliper

Calibration of Fourier Transform Infrared Spectrophotometer (FTIR)

Cleaning and operation of Moisture Analyzer

Cleaning & Operation of Vacuum pump in Quality Control Department

Operation and Calibration of Polarimeter

Cleaning and operation of Magnetic Stirrer

Cleaning Operation and Calibration of Melting Point

Operation Cleaning and Calibration of Muffle Furnance in Quality Control Department

procedure of operation and Cleaning of Sonicator

Operation Cleaning & Calibration of pH meter in Quality Control Department