sop for operation and calibration of dissolution Apparatus

1.0 OBJECTIVE

1.1 To describe a procedure for operation & calibration of Dissolution Apparatus.

2.0 SCOPE

2.1 This procedure is applicable for operation & calibration of Dissolution Apparatus to the Quality control department

3.0 RESPONSIBILITY

3.1 Officer/Executive – QC

4.0 ACCOUNTABILITY

4.1 Head – QC

5.0 PROCEDURE

5.1 Operating Procedure

5.1.1 Place the instrument on a table.

5.1.2 Place the bath and connect the tubes from the Inlet & Outlet of the temperature Controller.

5.1.3 Connect the Power Cord and Printer Cable.

5.1.4 Lift the stirrer Unit. Insert the shaft rod as per the method selected.

5.1.5 Place the Test Sample in the test vessel.

5.1.6 Press the DOWN Arrow key from the front panel to lower down the stirrer unit. The stirrer unit will adjust automatically

to required height depending on the test method selected.

5.1.7 Press the START key from the front panel to start the test. The instrument will now show the Run Time on screen.

5.1.8 The Run Time on screen will display the Protocol Running (Refer Idle Screen), The step No. (Refer option (c) in Parameter Setting),

The Elapsed Sampling Time for that particular Step

(Refer option (c) in Parameter setting), Actual RPM of stirrer (Refer option (a) in Parameter Setting), Actual Bath Temperature

and the Temperature being measured by the external probe (If Connected). The RUN LED on the Front Panel will glow indicating the instrument is in RUN Condition.

5.2 Procedure for Cleaning:

5.2.1 Switch OFF the power Supply of the instrument before removing water from the Bath.

5.2.2 Do not use aggressive solvents or material for cleaning the Bath and the Test Vessels.

5.2.3 Tube and Bath Cleaning: Fill half bath with liquid soap and circulate. Frequencyof cleaning once in a week.

This will prevent algae propagation in the bath.

5.2.4 Filters should be sonicated after every test and once in a week it should be flushed with methanol.

5.2.5 In case of any discrepancy or malfunction, attach status label and inform Maintenance department for cleaning.

5.3 Calibration

5.3.1 Physical Calibration

5.3.1.1 Calibration frequency: Quarterly or after major break down.

5.3.1.2 Calibration of bath temperature: Measured by the calibrated thermometer.

5.3.1.3 Calibration of vessel temperature using calibrated thermometer.

5.3.1.4 Permissible limit of temperature inside bath & vessel as per IP: 37.0°C + 0.5°C.

5.3.1.5 Calibration of RPM: Calibrate the RPM using calibrated tachometer.

5.3.1.6 Set one by one 50 & 100 RPM and check the actual RPM using calibrated tachometer.

5.3.1.7 Tolerance limit of RPM is + 4% of the reading.

5.3.1.8 Calibration of distance between blade and inside vessel as per IP: 25 mm + 2 mm

5.3.1.9 Checking of wobbling and distance parameters for the apparatus

5.3.1.10 Wobbling: Fix the paddle/basket apparatus to the instrument, lower the apparatus.

5.3.1.11 Fix the wobbling meter on the top of the bowl.

5.3.1.12 The needle of wobbling meter should touch to the surface of the apparatus.

5.3.1.13 Measure the wobbling on the meter.

5.3.1.14 Permissible limit of wobbling is NMT 1 mm on 360º revolution.

5.3.1.15 Distance from the apparatus: Fix the paddle/basket apparatus to the instrument, lower the apparatus.

5.3.1.16 Insert the Depth gauge between the bottom of the apparatus and the bottom of the bowl.

5.3.1.17 Measure the reading on the display.

5.3.1.18 Calibration of Timer: Set the time in instrument to 30 minutes. Start the equipment &stopwatch simultaneously. Note down the

time on the stopwatch when the set time is off displayed by equipment.

5.3.1.19 Jar Centering: Loosen the base plate of each jar, fix the centering device with spindle, lower down the spindle inside

the jar (Jar is automatically centered) and tighten the base plate of each jar. Fix the wobbling gauge in each jar,

rotate by 360° and record the reading.

5.3.1.20 Permissible limit of Jar Centering is NMT 2 mm on 360º revolution.

5.3.2

Performance Verification Test

5.3.2.1 Calibration frequency: Half yearly or after major maintenance job.

5.3.2.2 Performance Verification Test using IP Prednisone tablets.

5.3.2.3 Use disintegrating type Prednisone tablet having 10 mg claim.

5.3.2.4 Performance Verification Test applied for apparatus 1st and apparatus 2nd both.

5.3.2.5 Dissolution System :

Apparatus: Use specified type.

Duration: 30 minutes Speed: 50 rpm Temperature: 37.0°C + 0.5°C

Dissolution medium: 500 ml of purified water

5.3.2.6 Preparation of dissolution medium: Heat 500 ml of water for each vessel at 45°C and filtered with help of vacuum for

additional 5 minute continuous stirring. The temperature of

dissolution medium should be maintained at 37.0°C + 0.5°C prior to the initiation of test.

5.3.2.7 Preparation of standard solution in duplicate A & B: Weight accurately 0.030 gm of USP Prednisone working standard and

transfer into 200 ml volumetric flask. Added 10 ml ethanol and sonicate to dissolve if required. Dilute to volume with dissolution medium and mix.

Further dilute 5 ml of the resulting solution to 50 ml with dissolution medium and mix.

5.3.2.8 System suitability requirements: The test is not valid unless, the similarity factor between standard solutions

A & B (Separately prepared) is between 0.98 to 1.02. Calculate the similarity factor using following formula :

Absorbance of Prednisone Standard A obtain x weight of IP Prednisone WS with standard B

Absorbance of Prednisone Standard B obtain weight of IP Prednisone WS with standard A

(Note: If the similarity factor does not fall within 0.98 to 1.02, prepare fresh standard solution in duplicate and calculate similarity factor again as above.)

5.3.2.9 Preparation of sample solution: carry out the dissolution using six tablets. Transfer one tablet each separately into individual jar

containing 500 ml of dissolution medium. Ensure the temperature of all jars at the starting and the end of the set time using a calibrated

thermometer or temperature sensor. Set the stated parameters and carry out dissolution. At the end of the set time, immediately

withdraw 10 ml of the aliquot (the zone midway between the surface of the dissolution medium and the top of the rotating paddle/basket,

not less than 1 cm from the jar wall) and filter (0.45 µm syringe filter).

5.3.2.10 Procedure: Determine the absorbance of the standard solution and the sample solution at 240 nm using dissolution

medium as a blank. Calculate the percentage of Prednisone released per tablet by using the following formula.

Sample absorbance x weight of standard (mg) x 5 x 500 x 100 x purity of std. Absorbance of standard A x 200 x 50 x 1 x Label claim of tablet in mg x 100

5.3.2.11 Record the percentage dissolve obtained at the end of set time specified for the apparatus. Transform the percentage dissolve results to the natural log scale, and then determine the mean (M1) and variance (V1).

5.3.2.12 Convert result obtained in step 2 to a geometric mean (GM1) and percent coefficient of variation (%CV1). Compare the result obtained with the 1st stage of two-stage acceptance criteria.

5.3.2.13 Acceptance criteria: The GM must not fall outside the limit and % CV must not be greater than the limit and mentioned in the

certificate of IP Prednisone Tablets Reference Standard.

5.3.2.14 If the result of point 5.3.2.12 satisfy both acceptance criteria, the assembly has passed the Performance Verification test.

If the result obtained with 1st stage of two stages are not within acceptance criteria then follow the bellow procedure.

5.3.2.15 Carry out the dissolution with an additional set of tablets and repeat the point 5.3.2.9 and 5.3.2.10 again.

Transform the percentage dissolved results to the data obtained at this step.

5.3.2.16 Considering the average of the two mean (i.e. M1 & M2) and variance (i.e. V1 & V2) obtained in

point 5.3.2.11 and point 5.3.2.15 convert the result to geometric mean (GM) and percentage coefficient of variation (% CV).

5.3.2.17 Acceptance criteria: Compare the results obtained in point 5.3.2.16 with the 2nd stage of Two-Stage acceptance

criteria mentioned in the certificate of IP Prednisone tablets reference standard. The GM must not fall outside the limit and %CV must not be greater than the limit.

If both meet the acceptance criteria, the assembly has passed the performance verification test (PVT).

For calculation of geometric mean (GM) and % coefficient of variation (%CV) use the following formula and calculate the result.

For example :

Run 1 : X1,X2,……………Xn in natural log scale : LnX1,LnX2………..LnXn

Run 2 : Xn+1,Xn+2,……………X2n in natural log scale : LnXn+1,LnXn+2………..LnX2n

1st Stage of Two-Stage : For n = 6,7,8

GM1 = exp(average(Ln X1 : LnXn ) )

%CV1 = 100*sqrt(exp(var(Ln X1 : LnXn ) ) -1)

2nd Stage of Two-Stage :

GM = exp(avg(avg(Ln X1 : LnXn ) ), (avg( LnXn+1 : LnX2n ))))

= exp(avg(Ln X1 : LnX2n ))

%CV = 100*sqrt(exp(avg((var(Ln X1 : LnXn )),(var( LnXn+1 : LnX2n ))))-1)

Where,

exp : exponential

var : variance

sqrt : square root

100 : conversion factor to percentage

Ln : Natural log

avg : average

5.3.3 Calibration check by the external party :

5.3.3.1 Calibration frequency: yearly

5.3.3.2 Calibration of bath & vessel temperature: temperature controller with sensor reading.

5.3.3.3 Permissible limit of temperature inside bath & vessel as per IP: 37.0°C + 0.5°C

5.3.3.4 Calibration of RPM: Calibrate RPM using tachometer.

5.3.3.5 Set one by one 25, 50, 75,100,150 & 200 RPM and check the actual RPM using calibrated tachometer.

5.3.3.6 Tolerance limit of RPM is + 4% of the reading.

6.0 REFERENCE

6.1 In house

7.0 ENCLOSURES

Dissolution Apparatus Calibration

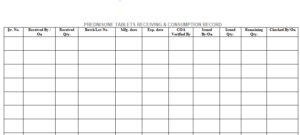

Prednisone tablet receiving & consumption record

8.0 FORMATS

8.1 QC : Quality Control

8.2 QA : Quality Assurance

8.3 QCA : Quality Control Analytical

8.4 SOP : Standard Operating Procedure

8.5 mg : Miligram

8.6 °C: Degree Centigrate

8.7 % : Percentage

8.8 IP: Indian Pharmacopoeia

8.9 ml: Milliliter

8.10 µm: Micrometer

8.11 µ: Micron

8.12 NMT: Not more than

8.13 PVT: Performance Verification Test

8.14 RPM: Round Per Minutes

8.15 mm: Micrometer

8.16 GM : Geometric mean

8.17 CV : Coefficient of variation

8.18 cm : Centimeter

8.19 gm : Gram

sop for Calibration and Maintenance of Laboratory Instruments and Equipment

Disposal of Residual Sample or Left Over Material

sop for for Laboratory Incident

standard operating procedure temperature monitoring

sop for operation of infrared moisture balance

sop for preparation of mobile phase

sop for Preparation and Issuance of Analysis protocol standard

sop of placebo and impurity stock solutions

sop for disposal of residual sample

sop for handling of pharmacopoeial changes

sop for procedure for operation of ultrasonic cleaner

difference between UPLC and HPLC

sop for for Emergency Eyewash and Shower

sop for operation and calibration of total organic carbon analyzers

sop for operation of cobb tester

sop for Operation and calibration of atomic absorption spectrophotometer

sop for Operation and calibration of gas liquid chromatograph

sop for operation of humidity oven

sop for operation and calibration of serological water bath

sop for monitoring of drain trap

sop for destruction of analytical samples after testing and control samples

sop for destruction of used chemicals

Sop for Operation of suction pump

sop for Operation and calibration uv cabinet

sop for Operation and calibration of bulk density apparatus

sop for operation and calibration of shore hardness tester

sop for operation of rub proofness tester

sop for monitoring of purified water

sop for Retesting of packaging materials

sop for Retesting and resampling of raw materials

sop for Control of issuance of record of analysis green sheets

sop for Control of computer passwords

sop for sampling of packaging materials PM

sop for sampling of sterile raw material

sop for sampling of intermediates and finished products

sop for operation and calibration of friability test apparatus

sop for approval and rejection of packaging materials

sop for non conformance of RM PM and finished product

sop for collection storage and disposal of control samples

sop for trend analysis of finished products

sop for Chromatographic practices and system suitability

SOP For Good Laboratory Practices

sop for cleaning and operation of sieve shaker

general specification of packing material cartons

sop for Password for Analytical Instrument and LIMS software

sop for Rounding off numerical analytical results

sop for sampling of bulk and finished product

sop for cleaning of spillage material

sop for Handling of Reference Standard

sop for hplc column maintenance and washing

procedure for sampling and handling of bulk sample

STP for borewell generation point (raw water storage tank)

sop for preparation and standardization of 0.1M Zinc Sulphate

Operation &calibration of analytical balance (dhona)

Operation and Calibration Procedure for Disintegration Test apparatus

sop for preparation and standardization of 1 M Hydrochloric Acid

Preparation and standardization of 0.1 M ceric ammonium sulphate solution

sop for preparation and standardization of 0.05 m iodine solution

validation of volumetric solution 0.1m ammonium thiocyanate

handling of reference standard and preparation of working standard

sop for water sampling and analysis

sop for operation for validation of excel worksheets

sop for stability of volumetric solutions

sop for preparation of raw material in process finish product packing material data sheets

sop for handling of hazardous chemicals

sop for handling of glassware and allocation of identification number

sop for operation cleaning and calibration of bursting strength tester

sop for rounding off the analytical test results

procedure for Analyst Qualification

sop for operation and calibration of dissolution Apparatus

procedure for maintenance of desiccators

sop for for hplc column receipt checking id no and regeneration

safety data sheet for laboratory chemicals

procedure for handling of poisonous chemicals

sop for cleaning of sampling devices

sop for calibration procedure of instruments

sop for specification and standard testing raw material packing material and finished product

procedure for operation and calibration of potentiometric titrator

procedure for operating and calibration of digital hardness tester

procedure for disposal of expired chemicals, reagents and solvents

sop for behavior in quality control department

sop for preparation and standardization 0.1M sodium thiosulphate

sop for preparation and standardization 0.1M Disodium Edetate

preparation and standardization 0.1M Sodium Hydroxide Solution

Preparation and standardization of 0.1M Perchloric acid solution

sop for preparation 0.05M edetate disodium

sop for preparation 0.1M silver nitrate

sop for Operation and Calibration of High Performance Liquid Chromatography

sop for UV & Visible Spectrophotometer

procedure for Cleaning of laboratory glassware

Cleaning of Instrument, Instrument bench and surrounding area of Quality

Safety Precaution in Quality Control Department

Operation & Calibration of Analytical Balance

Calibration of Glassware in Quality Control Department

handling of samples received in Quality Control

Cleaning and Operation of Refrigerator

Operation, Cleaning and Calibration of water bath

Operation & Calibration of Refractometer

Operation and Cleaning of Centrifuge Apparatus

cleaning, operation & calibration of Vernier caliper

Calibration of Fourier Transform Infrared Spectrophotometer (FTIR)

Cleaning and operation of Moisture Analyzer

Cleaning & Operation of Vacuum pump in Quality Control Department

Operation and Calibration of Polarimeter

Cleaning and operation of Magnetic Stirrer

Cleaning Operation and Calibration of Melting Point

Operation Cleaning and Calibration of Muffle Furnance in Quality Control Department

procedure of operation and Cleaning of Sonicator

Operation Cleaning & Calibration of pH meter in Quality Control Department