sop for Operation of Soft Water Plant

1.0 OBJECTIVE :

1.1 To lay down a procedure for operation of Soft water plant

2.0. SCOPE :

2.1 This procedure is applicable to operation of Soft Water plant

3.0. RESPONSIBILITY :

3.1 Operator Engineering Department shall be responsible for operation of Soft water Plant

3.2 Officer/Executive Engineering Department shall be responsible for to verify the proper operation of Soft water Plant

4.0. ACCOUNTABILITY :

4.1 Head Engineering Department shall be accountable for compliance of SOP.

5.0. PROCEDURE :

5.1 Operation Procedure of Soft Water Plant

5.1.1 Before starting the plant ensure backwash and rinse activity of MGF is done.

5.1.2 Keep Multiport Valve for backwash direction position (water flow down to up position) in MGF (Multi Grade Filter) for10 minute and drain the backwash water.

5.1.3 After backwash keep multiport valve position in rinse direction in MGF

(Multi Grade Filter ) for 10 min and drain the rinse water.

5.1.4 Start raw water pump, Water flows down to up position in Softener, Maintain flow 6000-7000LPH and water hardness less than 5 PPM

5.1.5 Collect Water in Soft Water Tank

5.1.6 Regenerate Softner after 100KL or if hardness more than 5PPM.

5.2 REGENERATION PROCESS

5.2.1 Make salt solution 35 Kgs in 100 Ltr Water in HDPE Tank and ensure that the solution shall be in clean condition.

5.2.2 Mix solution with compressed air/Stirrer. Keep Valve position in regeneration mode in Softner and connect solution tank with pipe and start soft water pump

5.2.3 Salt solution injection start from up to down direction, Drain the solution after 10 min rinse process.

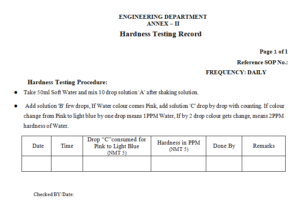

5.3 METHOD OF SOFT WATER HARDNESS TEST

5.3.1 Take 50ml Soft Water and mix 10 drop solution ‘A’ after shaking solution.

5.3.2 Add solution ‘B’ few drops, If Water colour comes Pink, add solution ‘C’ drop by drop with counting. If colour change from Pink to light blue by one drop means 1PPM Water, If by 2 drop colour gets change, means 2PPM hardness of Water. Take reading dally basis.

6.0 ABBREVIATION :

| Sr. No. | Abbreviation used | Full form of abbreviation used |

| 1. | SOP | Standard operating procedure |

| 2. | EM | Engineering and maintenance |

| 3. | MGF | Multi Grade Filter |

| 4. | PPM | Parts Per Millions |

7.0 ATTACHMENTS (ANNEXES) :

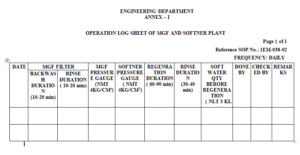

7.1 Annex-I: Operation log sheet of mgf and softener plant

7.2 Annex-II : Hardness Testing Record

8.0. REFERENCE :

In House

Annex-I: Operation log sheet of mgf and softener plant

Annex-II : Hardness Testing Record

sop for replacement of water system filters

cleaning and preventive maintenance of insectocutor

sop for operation of preventive maintenance

sop for material receiving and consumption record

sop for Preventive maintenance of bottle washing machine

sop for Replacement of Battery of Electronic Devices

sop for Preparation of R.O. Antiscalant Solution

Preventive Maintenance of Rapid Cooling Steam Sterilizer

Preventive Maintenance of Rapid cooling steam Generator

sop for Preventive Maintenance of Dust Collector

sop for Replacement of HVAC filters

SOP for Battery Backup in Mobile Laminar Air Flow Trolley

sop for Replacement of Tube lights

sop for Replacement of UV light of purified water plant

sop for Cleaning of soft water storage tank and RO feed tank

sop for Preparation of Sodium hydroxide Solution

sop for Operation and regeneration of softener plant

Procedure Of Issuance Of material from Engineering Store

sop for Preventive Maintenance of Filter Press

sop for Preventive Maintenance of Sugar Transfer System

sop for Preventive Maintenance of Shrink Sleeve Machine

sop for Preventive Maintenance of ROPP Cap Elevator

sop for Preventive Maintenance of Liquid Transfer Pumps

sop for Preventive Maintenance of Liquid Tanks

Preventive Maintenance of Strip De-Foiling Machine

sop for Preventive Maintenance of Colloidal Mill

sop for Preventive Maintenance of Packing Collator Belt

sop for Checking light intensity

sop for Operation of Fire- Extinguisher

sop for assigning identification to filters

sop for Engineering Spares Parts Inventory Control

sop for Colour Coding of Pipe line