sop for Continues Product Quality Review

1.0 OBJECTIVE:

1.1 To lay down a procedure for Continues Product Quality Review for the products manufactured in a every three months.

2.0 SCOPE:

2.1 This Standard Operating Procedure is applicable for all products manufactured

3.0 RESPONSIBILITY:

3.1 Officer / Executive – QA shall be responsible for collection of relevant data and information required for preparing Continues Product Quality Review.

3.2 Head-Quality Assurance shall be responsible for assuring that all provisions of this SOP are fulfilled and approval of Continues Product Quality Review.

4.0 ACCOUNTABILITY:

4.1 Head – QA

5.0 PROCEDURE:

5.1 All manufactured batches in every three months (Jan to Mar., Apr. to Jun, Jul to Sept., and Oct. to Dec.)

shall be considered for preparing the CPQR.

5.2 The data shall be collected from BMR and BPR.

5.3 Following details to be covered in CPQR.

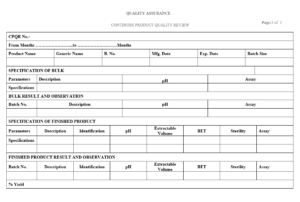

5.3.1 Product Description: Product details description i.e. Product name, Generic Name, Label Claim, Strength,

Batch Size, and any other specific information related to product shall be included.

5.3.2 Time Period Covered: Write the time period covered to prepare the CPQR.

5.3.3 Bulk Results and Observation: Collect the bulk data from BMR and BPR and summaries in CPQR.

5.3.4 Finished Product Result and Observation: Collect the finished data from BMR and BPR and summaries in CPQR.

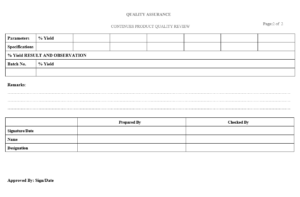

5.3.5 % Yield: Collect the % yield data from BMR and BPR and summaries in CPQR..

5.4 CPQR shall be number as per following numbering system

CPQR No. : CPQR/001, Where

CPQR: Signifies Continues Product Quality Review

001: Sequential Number of the CPQR (i.e., from 001 to 999)

5.5 Frequency: At every three months + 15 days.

5.6 Prepare the CPQR as per Annexure I.

6.0 ABBREVIATION:

| S. No. | Abbreviations used | Full form of Abbreviation used |

| 1. | QA | Quality Assurance |

| 2. | SOP | Standard Operating Procedure |

| 5. | BMR | Batch manufacturing record |

| 6. | BPR | Batch packing records |

| 7. | CPQR | Continues Product Quality Review |

7.0 ATTACHMENTS (ANNEXES) :

7.1 Annex –I : Continues Product Quality Review

8.0 REFERENCE :

| S. No. | Reference Title |

| 1.0 | As per WHO Guideline |

Annexure –I : Continues Product Quality Review

sop of general Non-Conformance incidence

Sop of Handling of out date documents

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

Protocol for re validation of dry heat sterilizer

sop for handling of external audits

sop for Checking of Proof and Overprinting

validation protocol of sterility test

sop for Analytical Method Transfer

process validation protocol for methylcobalamin niacinamide and pyridoxine injection

validation protocol of sterility test

sop for Analytical Method Transfer

Protocol for hold time study of sterile garments

sop for process validation

sop for swab sampling for validation of clean surfaces

cleaning validation maco and noel calculation formula

sop for performance qualification for analyst

Sop for Validation report for disinfectant efficacy

Sop for Method validation report for bacterial endotoxin test

Sop for method validation microbiology sterility testing

sop for validation report for preservative efficacy test

sop for Protocol cum report for efficacy qualification of uv light

sop for validation protocol for uv light efficacy of dpb & laf

sop for cleaning validation protocol tablet manufacturing equipment

sop for cleaning validation protocol ointment manufacturing equipment

concurrent process validation for rabeprazole ec and domperidone sr capsules

sop for Validation for cleaning procedure liquid injection

sop for Validation for cleaning procedure dry powder injection

Protocol for re validation of dry heat sterilizer

sop for Trend Analysis of QMS Documen