SOP For HPLC Column Maintenance and Washing

1.0 OBJECTIVE

1.1 To describe the procedure for the Maintenance, Column Washing and Usage Record of HPLC Column.

2.0 SCOPE

2.1 This SOP is applicable for the Maintenance, Column Washing and Usage Record of HPLC Column.

3.0 RESPONSIBILITY

3.1 QC Officer or QC Executive

4.0 ACCOUNTABILITY

4.1 QC Manager

5.0 Procedure

5.1 The Column has to be taken serial number has to be seen.

5.2 Check the column there should be no damage.

5.3 Check the Column according to Certificate of Analysis, make, serial number, supplier name, etc.

5.4 Change the mobile phase and column washing with HPLC grade water.

5.5 If everything complies of user requirement, make the entry of the column in as per Annexure also to be write the column ID.

5.6 The Column will be given according to the requirement as mentioned in the standard test procedure at that particular product.

5.7 If the Column Complies the system suitability criteria use the column for HPLC Instrument.

5.8 In case the Column does not complies system suitability Criteria than the column cannot even use an instrument.

HPLC should be tested for column specification.

5.9 Column Fail for system suitability parameter repetitively than it should be returned to the supplier.

5.10 Flush the column using warm water at 55°C at flow rate 0.5 ml/min for 15 minutes. Maintain the

Column temp. at 55°C in the column oven.

5.11 Flush the Methanol : Water (50 : 50) flow rate 0.5 ml/min in 60 minutes.

5.12 Change the Mobile Phase from water to HPLC Grade 80 % Acetonitrile.

5.13 Flush the column using HPLC Water 0.5 ml/min for atleast one hour.

5.14 Disconnect the column from the HPLC instrument and store in an appropriate place.

5.15 Do not use the mobile phase having pH out of the range given in the column.

5.16 Do not over tight the ferrules of the column.

5.17 Wash the column properly minimum for 60 min, the water, methanol & Acetonitrile or specified

solvent given for the column washing.

6.0 ABBREVIATIONS

| Sr. No. | Abbreviation used | Extended Form |

| 1.0 | SOP | Standard Operating Procedure |

| 2.0 | No | Number |

| 3.0 | QC | Quality Control |

7.0 ATTACHMENTS

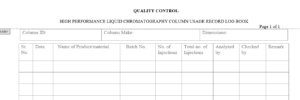

Annexure-1 : HPLC Column Usage Entry log Book.

8.0 REFERENCE

| Sr. No. | Reference Title |

| 01. | In-House |

Annexure-1 : HPLC Column Usage Entry log Book

sop for cleaning of spillage material

sop for Handling of Reference Standard

sop for hplc column maintenance and washing

procedure for sampling and handling of bulk sample

STP for borewell generation point (raw water storage tank)

sop for preparation and standardization of 0.1M Zinc Sulphate

Operation &calibration of analytical balance (dhona)

Operation and Calibration Procedure for Disintegration Test apparatus

sop for preparation and standardization of 1 M Hydrochloric Acid

Preparation and standardization of 0.1 M ceric ammonium sulphate solution

sop for preparation and standardization of 0.05 m iodine solution

validation of volumetric solution 0.1m ammonium thiocyanate

handling of reference standard and preparation of working standard

sop for water sampling and analysis

sop for operation for validation of excel worksheets

sop for stability of volumetric solutions

sop for preparation of raw material in process finish product packing material data sheets

sop for handling of hazardous chemicals

sop for handling of glassware and allocation of identification number

sop for operation cleaning and calibration of bursting strength tester

sop for rounding off the analytical test results

procedure for Analyst Qualification

sop for operation and calibration of dissolution Apparatus

procedure for maintenance of desiccators

sop for for hplc column receipt checking id no and regeneration

safety data sheet for laboratory chemicals

procedure for handling of poisonous chemicals

sop for cleaning of sampling devices

sop for calibration procedure of instruments

sop for specification and standard testing raw material packing material and finished product

procedure for operation and calibration of potentiometric titrator

procedure for operating and calibration of digital hardness tester

procedure for disposal of expired chemicals, reagents and solvents

sop for behavior in quality control department

sop for preparation and standardization 0.1M sodium thiosulphate

sop for preparation and standardization 0.1M Disodium Edetate

preparation and standardization 0.1M Sodium Hydroxide Solution

Preparation and standardization of 0.1M Perchloric acid solution

sop for preparation 0.05M edetate disodium

sop for preparation 0.1M silver nitrate

sop for Operation and Calibration of High Performance Liquid Chromatography

sop for UV & Visible Spectrophotometer

procedure for Cleaning of laboratory glassware

Cleaning of Instrument, Instrument bench and surrounding area of Quality

Safety Precaution in Quality Control Department

Operation & Calibration of Analytical Balance

Calibration of Glassware in Quality Control Department

handling of samples received in Quality Control

Cleaning and Operation of Refrigerator

Operation, Cleaning and Calibration of water bath

Operation & Calibration of Refractometer

Operation and Cleaning of Centrifuge Apparatus

cleaning, operation & calibration of Vernier caliper

Calibration of Fourier Transform Infrared Spectrophotometer (FTIR)

Cleaning and operation of Moisture Analyzer

Cleaning & Operation of Vacuum pump in Quality Control Department

Operation and Calibration of Polarimeter

Cleaning and operation of Magnetic Stirrer

Cleaning Operation and Calibration of Melting Point

Operation Cleaning and Calibration of Muffle Furnance in Quality Control Department

procedure of operation and Cleaning of Sonicator

Operation Cleaning & Calibration of pH meter in Quality Control Department

Entry and Exit in Quality Control Department