sop of Cleaning of Barrel Pump

1.0 Objective

To lay down a procedure for cleaning of barrel pump.

2.0 Scope

This Standard Operating Procedure is applicable for cleaning of barrel pump to be followed at

formulation plants of A B C Company

3.0 Responsibility

3.1 Officer / Executive warehouse shall be responsible for the cleaning of barrel pump.

3.2 Head Warehouse is responsible for implementation of this SOP.

3.3 Head QA or his designee shall be responsible for compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

No : Number

QA : Quality Assurance

WH : Warehouse

HOD : Head of Department

5.0 Procedure

5.1 Keep the “To be cleaned” barrel pump into the poly bag and tie it with cable tie.

5.2 Bring it into the washing room.

5.3 Take the required quantity of purified water in the container.

5.4 Deep the barrel pumps into the purified water.

5.5 Rotate the barrel pump into clockwise direction and then into anticlockwise direction

for 10 minutes and after then the barrel pump for dry.

5.6 Cover the barrel pump with the poly bag.

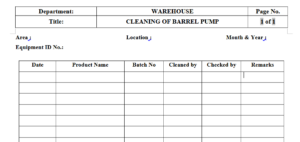

5.7 Record the cleaning activity in Annexure – 1.

5.8 Cleaning of barrel pump shall be done after end of the using operation.

6.0 Forms and Records

6.1 Cleaning of Barrel Pump – Annexure-1.

7.0 Distribution

7.1 Master Copy – Documentation Cell (Quality Assurance)

7.2 Controlled Copy – Warehouse Department.

8.0 History

-

Revision Number

Details For Change

Reason for Revision

00

New SOP

NA

Cleaning of Barrel Pump – Annexure-1.

sop for Execution of Preventive Maintenance

Preparation of Sodium Hydroxide Solution

sop for water cooled chiller operation

cleaning and preventive maintenance of LAF and RLAF

sop for replacement of water system filters

cleaning and preventive maintenance of insectocutor

sop for operation of preventive maintenance

sop for material receiving and consumption record

sop for Preventive maintenance of bottle washing machine

sop for Replacement of Battery of Electronic Devices

sop for Preparation of R.O. Antiscalant Solution

Preventive Maintenance of Rapid Cooling Steam Sterilizer

Preventive Maintenance of Rapid cooling steam Generator

sop for Preventive Maintenance of Dust Collector

sop for Replacement of HVAC filters

SOP for Battery Backup in Mobile Laminar Air Flow Trolley

sop for Replacement of Tube lights

sop for Replacement of UV light of purified water plant

sop for Cleaning of soft water storage tank and RO feed tank

sop for Preparation of Sodium hydroxide Solution

sop for Operation and regeneration of softener plant

Procedure Of Issuance Of material from Engineering Store

sop for Preventive Maintenance of Filter Press

sop for Preventive Maintenance of Sugar Transfer System

sop for Preventive Maintenance of Shrink Sleeve Machine

sop for Preventive Maintenance of ROPP Cap Elevator

sop for Preventive Maintenance of Liquid Transfer Pumps

sop for Preventive Maintenance of Liquid Tanks

Preventive Maintenance of Strip De-Foiling Machine

sop for Preventive Maintenance of Colloidal Mill

sop for Preventive Maintenance of Packing Collator Belt

sop for Checking light intensity

sop for Operation of Fire- Extinguisher

sop for assigning identification to filters

sop for Engineering Spares Parts Inventory Control

sop of Cleaning of Barrel Pump