Preventive Maintenance of Building premises and surrounding

1.0 OBJECTIVE :

1.1 To lay down a procedure for carrying out Preventive maintenance of building, premises and surroundings.

2.0. SCOPE :

2.1 This procedure covers painting, civil work to be done in case of wear and tear, maintenance of the door closures, repair of the leakages through valves and taps carrying water.

3.0. RESPONSIBILITY :

3.1 Engineering department is responsible for maintenance and up keeping of buildings, premises and surrounding areas by carrying out necessary inspection and repair jobs wherever necessary or periodically.

4.0. ACCOUNTABILITY :

4.1 Head of Engineering Department shall be responsible for compliance of SOP.

5.0. PROCEDURE :

5.1 Repaint inside walls and ceilings at the interval of six years and maintain the record as per Annex -I.

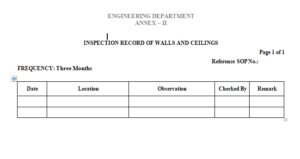

5.2 Carry out the inspection of the plant at the interval of three months to find out whether any part of the plant requires repainting and maintain the record as per Annex –II.

5.3 Inspect the plant for wear and tear and crevices in the walls, sealing and floor. Carry out civil work as and when required and maintain the record as per Annex –II.

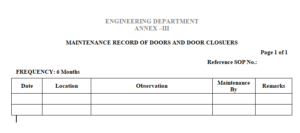

5.4 Carry out maintenance of the door and door closures every 6 months and maintain the record as per Annex -III.

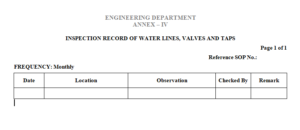

5.5 Inspect the plant every month to find out leakages in the water lines, valves, taps and repair the same and maintain the record as per Annex-IV.

5.6 Maintain record as per frequency of all observation as per Annex – I, Annex – II, Annex – III and Annex -IV of this SOP.

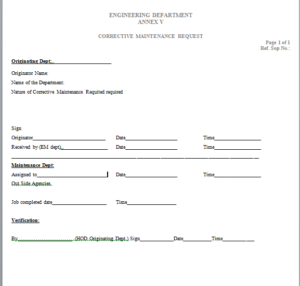

5.7 HOD shall generate Annex-V ( Corrective maintenance Request ), Whenever he find any maintenance required in his department in two copies and shall forward to Head Engineering all the copies.

5.8 After receiving the Annex-V, Head engineering shall acknowledge the receipt of the Annex-V on all two copies with date and time of receipt of Annex-V, keep first copy of Annex-V with EM Department and second copy shall be returned to originating department.

5.9 Head engineering shall assign the work to person of EM Department or out side agencies with in a day of the receipt of the Annex-V.

5.10 EM personnel shall rectify the corrective maintenance of Annex-V or shall get it done through out side agencies.

5.11 EM personnel shall fill up the data in Annex-V

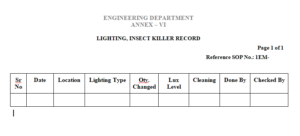

5.12 Light cleaning shall be done on monthly basis. Defective light, Insect Killer shall be changed on requirement bass and maintained record in Annex-VI

5.13 Lux shall be checked on Quarterly basis and maintained record in Annex-VI

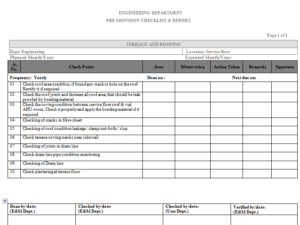

5.14 Pre monsoon shall be done on Yearly Basis & maintained record in Annex-VII

5.15 Check roof, joints, coving condition, cracks and leakage, maintained record on Annex- II. If found any major crack / damage, then contact to civil contractor for repairing

5.16 EM personnel shall be responsible for fill up the data and handle the all observed or reported civil / technical problem from concern department and head engineering shall be responsible to ensure the compliance.

6.0. ABBREVIATION :

| Sr. No. | Abbreviation used | Full form of abbreviation used |

| 1. | SOP | Standard operating procedure |

| 2. | EM | Engineering and maintenance |

7.0 ATTACHMENTS (ANNEXES) :

Annex – I : Repaint Record Of Walls And Ceilings

Annex – II : Inspection Record of Walls And Ceilings

Annex – III : Maintenance Record of Doors And Door Closures

Annex – IV : Inspection Record of Water Lines, Valves And Taps

Annex – V : Corrective Maintenance Request

Annex – VI : Lighting, Insect Killer Record

Annex – VII : Pre Mansoon Checklist and Report

8.0. REFERENCE :

In House

Annex – I : Repaint Record Of Walls And Ceilings

Annex – II : Inspection Record of Walls And Ceilings

Annex – III : Maintenance Record of Doors And Door Closures

Annex – IV : Inspection Record of Water Lines, Valves And Taps

Annex – V : Corrective Maintenance Request

Annex – VI : Lighting, Insect Killer Record

Annex – VII : Pre Mansoon Checklist & Report

sop for Execution of Preventive Maintenance

Preparation of Sodium Hydroxide Solution

sop for water cooled chiller operation

cleaning and preventive maintenance of LAF and RLAF

sop for replacement of water system filters

cleaning and preventive maintenance of insectocutor

sop for operation of preventive maintenance

sop for material receiving and consumption record

sop for Preventive maintenance of bottle washing machine

sop for Replacement of Battery of Electronic Devices

sop for Preparation of R.O. Antiscalant Solution

Preventive Maintenance of Rapid Cooling Steam Sterilizer

Preventive Maintenance of Rapid cooling steam Generator

sop for Preventive Maintenance of Dust Collector

sop for Replacement of HVAC filters

SOP for Battery Backup in Mobile Laminar Air Flow Trolley

sop for Replacement of Tube lights

sop for Replacement of UV light of purified water plant

sop for Cleaning of soft water storage tank and RO feed tank

sop for Preparation of Sodium hydroxide Solution

sop for Operation and regeneration of softener plant

Procedure Of Issuance Of material from Engineering Store

sop for Preventive Maintenance of Filter Press

sop for Preventive Maintenance of Sugar Transfer System

sop for Preventive Maintenance of Shrink Sleeve Machine

sop for Preventive Maintenance of ROPP Cap Elevator

sop for Preventive Maintenance of Liquid Transfer Pumps

sop for Preventive Maintenance of Liquid Tanks

Preventive Maintenance of Strip De-Foiling Machine

sop for Preventive Maintenance of Colloidal Mill

sop for Preventive Maintenance of Packing Collator Belt

sop for Checking light intensity

sop for Operation of Fire- Extinguisher

sop for assigning identification to filters