sop for Fire Fighting

1.0 OBJECTIVE

1.1 The objective of this SOP is to define the procedure for Fire Fighting to prevent loss of life and property due to fire.

2.0 SCOPE

2.1 This procedure applies to the Fire Fighting at ……………..

3.0 RESPONSIBILITY

3.1 Officer – H.R. and Administration & Security Head.

3.2 Maintenance-Incharge- – To maintain all instruments related to fire fighting and record of same.

4.0 ACCOUNTABILITY

4.1 Head -H.R. and Administration

5.0 REFERENCE(S)

5.1 In- house.

6.0 ENVIRONMENT, HEALTH AND SAFETY

6.1 Put on hand gloves while used the Hydrants pipe.

6.2 Be aware with electronic panel,

6.3 All Hydrants should be used carefully.

7.0 PROCEDURE

7.1 Drills for fire fighting

7.1.1 Evacuation Drill

7.1.1.1 Auto activation of fire alarm.

7.1.1.2 Announcement will be made from admin dept.

7.1.1.3 All departments will be evacuated as per drill rehearsed.

7.1.1.4 Department Heads will be responsible for evacuation of their respective departments.

7.1.1.5 All personnel will gather in the assembly point.

7.1.2 Fire Fighting

7.1.2.1 Use fire extinguisher available immediately to douse fire.

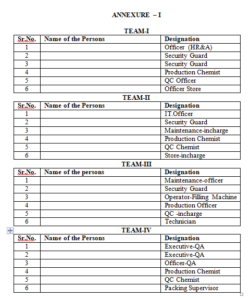

7.1.2.2 Hydrants will be manned by team as per annexure – I.

7.1.2.3 The dept. where fire is noticed will immediately inform dept. Head, Chief Executive Officer, Head- H.R, and Maintenance-Incharge.

7.1.2.4 Pump will be switched on by the personnel on duty.

7.1.2.5 Additional hose will be fixed near the place of fire.

7.1.2.6 Utility Maintenance-Incharge., Head-Admin and Security Incharge. will be responsible to oversee the oversee the operations of fire fighting.

7.1.2.7 Inform fire brigade if fire cannot be controlled locally.

7.1.3 Evacuation of causalities

7.1.3.1 All causalities will be evacuated to local Registered Hospital,

7.2 The persons responsible for the evacuation of causalities are mentioned in ‘Team – I’ as per annexure – I (Format No. )

7.3 Maintenance of fire fighting equipment

Responsibility

7.3.1 Fire Extinguishers Utility

7.3.2 Hydrants Utility

7.3.3 Fire Points Utility

8.0 HISTORY

| SOP NO. | REASON FOR CHANGE | REVISION

NUMBER |

CHANGE CONTROL NUMBER | EFFECTIVE

DATE |

| New SOP | 00 | NA |

9.0 ABBREVIATIONS:

NA : Not Applicable

No. : Number

SOP : Standard Operating Procedure

H.R. : Human Resource

10.0 ANNEXURE

| Annexure No. | Title of Annexure | Format No. of Annexure |

| Annexure–I | Fire Fighting Team |

sop for Cleaning of Ampoule Filling and Sealing Machine

sop for Fogging in Sterile and Non Sterile Area

sop for for Filtration of Bulk Solution

sop for fumigation in production area

sop for post cleaning after media fill

sop for cip of mixing vessel mixing mobile vessel and holding vessel

sop for De-Bagging of Three Piece Vial Dropper Caps

sop for calibration and verification of check weigher

sop for Batch number and Manufacturing and Expiry Date Coding System

standard operating procedure machine history file

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for for charge hand over between the shifts

Performance requalification report of visual inspectors

sop for Cleaning and operation of ROPP caps inspection table

sop for usage and destruction of filter pad and cartridge filter

sop for cleaning and storage of transfer pipe

sop for Cleaning and operation of labeling machine

Cleaning and operation of the mono block filling and sealing machine

sop for Cleaning and operation of empty bottle inspection table

sop for Cleaning and operation of filter press

sop for cleaning and operation of liquid transfer pump and line

sop for cleaning and operation of storage vessels

sop for cleaning and operation of sugar syrup manufacturing vessel

sop for cleaning issuance and retrieval of accessories and change parts

sop for Cleaning and operation of visual inspection conveyor belt