preparation for Sampling Intimation slip

1.0 OBJECTIVE:

To lay down a Sampling Intimation for Process Validation / Equipment Qualification / Utility Qualification Cleaning Validation / Hold time study samples.

2.0 SCOPE:

This SOP is applicable for Sampling Intimation for Process Validation / Equipment Qualification / Utility Qualification / Cleaning validation / Hold time study samples at ………..

3.0 RESPONSIBILITY:

Officer / Executive QA

4.0 ACCOUNTABILITY:

Head QA

5.0 PROCEDURE:

5.1.1 BMR and BPR completion up to respective stage.

5.1.2 Availability of cleaned equipment’s i.e. sampling rod / spatula / Swab.

5.1.3 Personnel protective equipment’s such as nose mask and hand gloves should be used properly during any activity.

5.1.4 Availability of sampling bags along with status label.

5.1.5 Processing stage i.e. in process bulk / semi finish / finished products.

5.1.6 Product details on request intimation for in process sample / finished products.

5.2 SAMPLING FOR VALIDATION / QUALIFICATION/CLEANING/HOLD TIME ACTIVITY:

5.2.1 Sampling for Validation / Qualification activity shall be performed by the trained persons only.

5.2.2 Officer / Executive QA involved in the validation / Qualification activity shall collect the samples of in process product or material at different stages as per the sampling plan mentioned in the validation / Qualification protocol.

5.2.3 Collected samples shall be packed properly in suitable container with adequate protection for light, moisture and temperature as per requirement.

5.2.4 Executive / Officer QC shall fill the intimation slip as per their respective Annexures:

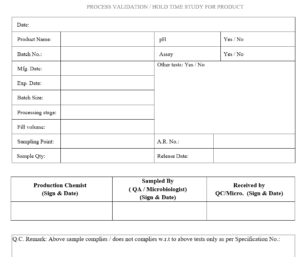

For Process validation / Hold time study for product in Annexure-I.

For Sample Intimation Slip For Qualification as per Annexure-II

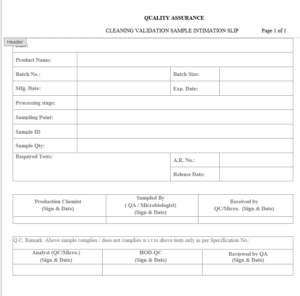

For Sample Intimation Slip For Cleaning Validation as per Annexure-III

6.0 ABBREVIATIONS:

| Sr. No. | Abbreviation used | Full form of abbreviation used |

| 1. | QA | Quality Assurance |

| 2. | SOP | Standard Operating Procedure |

| 3. | Gm | Gram |

| 4. | No. | Number |

| 5. | Ltd. | Limited |

7.0 ATTACHMENTS (ANNEXES) :

Annex-I : Process validation / Hold time study for product

Annex-II : Sample Intimation Slip for Qualification

Annex-III : Cleaning validation Sample Intimation Slip

8.0 REFERENCES:

| Sr. No. | Reference Title |

| 1.0 | In house

|

Annex-I : Process validation / Hold time study for product

Annex-II : Sample Intimation Slip for Qualification

Annex-III : Cleaning validation Sample Intimation Slip

preparation for sampling Intimation slip

Online Rejection in parenteral

Receipt of Batch from Production to Packing Department

sop for for Spillage Handling in parenteral area

sop for calibration of vessels with dipstick

sop for Cleaning of Bins and Containers

cip of mixing vessel and holding vessel

sop for Cleaning of Ampoule Filling and Sealing Machine

sop for Fogging in Sterile and Non Sterile Area

sop for for Filtration of Bulk Solution

sop for fumigation in production area

sop for post cleaning after media fill

sop for cip of mixing vessel mixing mobile vessel and holding vessel

sop for De-Bagging of Three Piece Vial Dropper Caps

sop for calibration and verification of check weigher

sop for Batch number and Manufacturing and Expiry Date Coding System

standard operating procedure machine history file

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for for charge hand over between the shifts

Performance requalification report of visual inspectors

sop for Cleaning and operation of ROPP caps inspection table

sop for usage and destruction of filter pad and cartridge filter

sop for cleaning and storage of transfer pipe

sop for Cleaning and operation of labeling machine

Cleaning and operation of the mono block filling and sealing machine

sop for Cleaning and operation of empty bottle inspection table

sop for Cleaning and operation of filter press

sop for cleaning and operation of liquid transfer pump and line

sop for cleaning and operation of storage vessels

sop for cleaning and operation of sugar syrup manufacturing vessel

sop for cleaning issuance and retrieval of accessories and change parts

sop for Cleaning and operation of visual inspection conveyor belt

sop for Cleaning and operation of spray gun and assemble

sop for Fogging in Aseptic and Non Aseptic Area