SOP for Cleaning of Change Rooms

1.0 Objective

To lay down guidelines of procedure for Change Room Cleaning.

2.0 Scope

This procedure is applicable for Change Room Cleaning at abc company.

3.0 Responsibility

3.1 All Supervisor of HR & Administration

3.2 Manager/ Head Concern Area

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

HR : Human Resource

CC NO : Change Control Number

cGMP : Current Good Manufacturing Practice

HOD : Head of Department

5.0 Procedure

5.1 Change room cleaning

5.1.1 Doors, door closures, handle window glasses, fire extinguishers, emergency lights,

switchboards, coving, corners of the entire area cleaned daily.

5.1.2 Clean and mop the entire floor in 1st half & 2nd half.

5.1.3 Tube light fixture, walls, ceiling and corner angle cleaned once a week.

5.1.4 Clean the door, window glasses and locker from top progressing to downwards.

Using (Disinfectant solution) wet duster.

5.1.5 Clean the switch boards using dry duster.

5.1.6 Clean the coving, corners of the entire area using wet (with disinfectant) duster.

5.1.7 Clean the ceiling, walls and corner angles using wet duster followed by dry duster. (Once a week).

5.1.8 Clean and mop the entire floor using 2.5% disinfectant solution (Dettol / Savlon/ Phenyl 5.0 %)

Using Scrubber cum dryer /Aluminum stick mop at the start and at the end of the shift or as and when required.

5.1.9 Disinfectant should be change every three days to prevent the bacterial resistance.

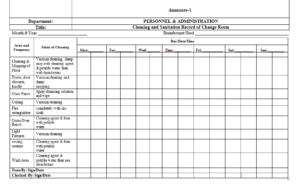

5.1.10 Enter the cleaning details in the “change room cleaning Record” as per Annexure-I.

5.1.11 Clean the tube lights fixtures using dry duster (once a week).

6.0 Forms and Records

6.1 Cleaning and Sanitation Record of Change Room – Annexure-1.

7.0 Distribution

7.1 Master Copy – Documentation Cell (Quality Assurance)

7.2 Controlled Copy – Quality Assurance, Personnel & Administration, Production

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

Online Rejection in parenteral

Receipt of Batch from Production to Packing Department

sop for for Spillage Handling in parenteral area

sop for calibration of vessels with dipstick

sop for Cleaning of Bins and Containers

cip of mixing vessel and holding vessel

sop for Cleaning of Ampoule Filling and Sealing Machine

sop for Fogging in Sterile and Non Sterile Area

sop for for Filtration of Bulk Solution

sop for fumigation in production area

sop for post cleaning after media fill

sop for cip of mixing vessel mixing mobile vessel and holding vessel

sop for De-Bagging of Three Piece Vial Dropper Caps

sop for calibration and verification of check weigher

sop for Batch number and Manufacturing and Expiry Date Coding System

standard operating procedure machine history file

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for for charge hand over between the shifts

Performance requalification report of visual inspectors

sop for Cleaning and operation of ROPP caps inspection table

sop for usage and destruction of filter pad and cartridge filter

sop for cleaning and storage of transfer pipe

sop for Cleaning and operation of labeling machine

Cleaning and operation of the mono block filling and sealing machine

sop for Cleaning and operation of empty bottle inspection table

sop for Cleaning and operation of filter press

sop for cleaning and operation of liquid transfer pump and line

sop for cleaning and operation of storage vessels

sop for cleaning and operation of sugar syrup manufacturing vessel

sop for cleaning issuance and retrieval of accessories and change parts

sop for Cleaning and operation of visual inspection conveyor belt

sop for Cleaning and operation of spray gun and assemble

sop for Fogging in Aseptic and Non Aseptic Area

Cleaning And Assembly Of Tube Filling Machine

Proper Handling of Non Recoverable Residues

sop for Handling Of Off Line Packing

Air Washing Of Collapsible Tube

sop for Pest and Rodent Control

Cleaning of Uniforms (Factory cloths)

sop for General Instruction For Employees

Key Deposition and Issuing Procedure