sop for cleaning of Dosing tank

1.0 OBJECTIVE :

1.1 To lay down a procedure for cleaning of Dosing tank.

2.0. SCOPE :

2.1 This procedure is applicable to all the Dosing tanks situated at Pharma Dekho

3.0. RESPONSIBILITY :

3.1 Operator Engineering Department shall be responsible for cleaning of Dosing tanks and maintaining the cleaning records.

3.2 Officer/Executive Engineering Department shall be responsible for to verify the proper cleaning of Dosing tanks.

4.0. ACCOUNTABILITY :

4.1 Head Engineering Department shall be accountable for compliance of SOP.

5.0. PROCEDURE :

5.1 CLEANING OF DOSING TANK

5.1.1 Switch OFF the Dosing pump.

5.1.2 Pump out the Solution fully from Dosing tank and ensure that the tank is empty for cleaning.

5.1.3 Open the covers of the Dosing tank

5.1.4 Clean the tank surface & Floor with cloth.

5.1.5 Flush the tank with fresh water for 10 minutes, drain out/ pump out the waste water from the tank.

5.1.6 Apply 4% v/v Sodium Hypochlorite Solution (commercial grade) on the surface and floor of the tank.

5.1.7 Keep it for half an hour and then flush with fresh water and drain out/ pump out the waste water.

5.1.8 Continue the flushing for 10 minutes.

5.1.9 After flushing, test the rinse water for residual chlorine (Limit- Nil) and pH shall between 5-7 and pH.

5.1.10 If residual chlorine and pH of the sample is same as fresh water, stop the rinsing and close the tank covers. If it is not as fresh water, continue the rinsing till obtain same quality.

5.1.11 After ensuring the quality, Start & prepare the solution as per SOP

5.1.12 Frequency of cleaning: Weekly

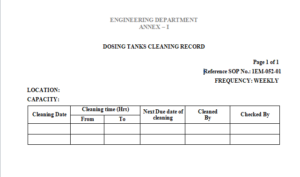

5.1.13 Maintain the cleaning record in Annex-I.

6.0. ABBREVIATION :

| Sr. No. | Abbreviation used | Full form of abbreviation used |

| 1. | SOP | Standard operating procedure |

| 2. | EM | Engineering and maintenance |

7.0 ATTACHMENTS (ANNEXES) :

Annex-I : Dosing Tanks Cleaning Record

8.0. REFERENCE :

In House

Annex-I : Dosing Tanks Cleaning Record

Online Rejection in parenteral

Receipt of Batch from Production to Packing Department

sop for for Spillage Handling in parenteral area

sop for calibration of vessels with dipstick

sop for Cleaning of Bins and Containers

cip of mixing vessel and holding vessel

sop for Cleaning of Ampoule Filling and Sealing Machine

sop for Fogging in Sterile and Non Sterile Area

sop for for Filtration of Bulk Solution

sop for fumigation in production area

sop for post cleaning after media fill

sop for cip of mixing vessel mixing mobile vessel and holding vessel

sop for De-Bagging of Three Piece Vial Dropper Caps

sop for calibration and verification of check weigher

sop for Batch number and Manufacturing and Expiry Date Coding System

standard operating procedure machine history file

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for for charge hand over between the shifts

Performance requalification report of visual inspectors

sop for Cleaning and operation of ROPP caps inspection table

sop for usage and destruction of filter pad and cartridge filter

sop for cleaning and storage of transfer pipe

sop for Cleaning and operation of labeling machine

Cleaning and operation of the mono block filling and sealing machine

sop for Cleaning and operation of empty bottle inspection table

sop for Cleaning and operation of filter press

sop for cleaning and operation of liquid transfer pump and line

sop for cleaning and operation of storage vessels

sop for cleaning and operation of sugar syrup manufacturing vessel

sop for cleaning issuance and retrieval of accessories and change parts

sop for Cleaning and operation of visual inspection conveyor belt

sop for Cleaning and operation of spray gun and assemble

sop for Cleaning of Air Handling Unit Ducting

sop for Uninterrupted Power Supply UPS

sop for Operation of Chiller and Pumps

sop for Preventive Maintenance of Equipments and Machineries

sop for cleaning of Dosing tank

Great information shared.. really enjoyed reading this post thank you author for sharing this post .. appreciated