sop for Sanitization of Seals

1.0 OBJECTIVE:

To lay down the procedure for Sanitization of Seals.

2.0 SCOPE:

This SOP is applicable to Sanitization of Seals in Production Area

3.0 RESPONSIBILITY:

Officer / Executive – Production

4.0 ACCOUNTABILITY:

Head – Production

5.0 DEFINITIONS:

Not Applicable

6.0 PROCEDURE:

6.1 Collect the dispensed seals and checked the quantity from BPR and bring them to washing and sterilization room.

6.2 Ensure that the IPA container is cleaned and sterilized.

6.3 Open the seal bag from upper side and dipped into 70% IPA container.

6.4 Ensure that empty container for seal is cleaned and sterilized.

6.5 After dipped seals from IPA container bring them into clean and sterilized Empty container and send the container to sealing Area through dynamic pass box.

Restricted Circulation

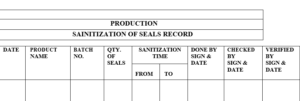

6.6 Record the sanitization time and quantity of seals in Annexure I

7.0 ABBREVIATION:

SOP Standard Operating Procedure

IPA Iso Propyl Alcohol

SS Stainless Steel

PD Production Department

BPR Batch Packing Record

8.0 ANNEXURES:

Sanitization of Seals Record

9.0 DISTRIBUTION:

• Controlled Copy No.1 Production Department

• Master Copy Quality Assurance Department

10.0 REFRENCE:

Not Applicable

11.0 REVISION HISTORY:

ANNEXURE I

Online Rejection in parenteral

Receipt of Batch from Production to Packing Department

sop for for Spillage Handling in parenteral area

sop for calibration of vessels with dipstick

sop for Cleaning of Bins and Containers

cip of mixing vessel and holding vessel

sop for Cleaning of Ampoule Filling and Sealing Machine

sop for Fogging in Sterile and Non Sterile Area

sop for for Filtration of Bulk Solution

sop for fumigation in production area

sop for post cleaning after media fill

sop for cip of mixing vessel mixing mobile vessel and holding vessel

sop for De-Bagging of Three Piece Vial Dropper Caps

sop for calibration and verification of check weigher

sop for Batch number and Manufacturing and Expiry Date Coding System

standard operating procedure machine history file

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for for charge hand over between the shifts

Performance requalification report of visual inspectors

sop for Cleaning and operation of ROPP caps inspection table

sop for usage and destruction of filter pad and cartridge filter

sop for cleaning and storage of transfer pipe

sop for Cleaning and operation of labeling machine

Cleaning and operation of the mono block filling and sealing machine

sop for Cleaning and operation of empty bottle inspection table

sop for Cleaning and operation of filter press

sop for cleaning and operation of liquid transfer pump and line

sop for cleaning and operation of storage vessels

sop for cleaning and operation of sugar syrup manufacturing vessel

sop for cleaning issuance and retrieval of accessories and change parts

sop for Cleaning and operation of visual inspection conveyor belt

sop for Cleaning and operation of spray gun and assemble

sop for Fogging in Aseptic and Non Aseptic Area