sop for in-process control on liquids orals

1.0 OBJECTIVE

To ensure quality of product during Washing, Filling, Sealing, Inspection, Labeling and packaging operation of Liquid Orals.

2.0 RESPONSIBILITY

Quality Assurance Officer

3.0 ACCOUNTABILITY

Quality Assurance Manager.

4.0 PROCEDURE

4.1 START UP

Washing / Filling / Sealing and Inspection

4.1.1 Ensure that the relevant BMR is filled up to the previous stage and available in the Liquid

Filling area.

4.1.2 Ensure that the relative humidity and temperature of the Liquid filling area is within the limits prescribed in the Manufacturing Instructions

4.1.3 Ensure that the status tag , giving details of the Product to be filled and Batch Number is affixed on the machine.

4.1.4 Ensure that the Batch Number of the Bulk is the same as mentioned in the BMR.

4.1.5 Ensure that the Vessels containing Bulk have ‘APPROVED’ label on them.

4.1.6 Check the In Process Control Chart and ensure that the Production Officer has filled in the relevant columns giving product details.

4.1.7 After all the physical parameters have been set and the machine is in operation, collect sample and check

the physical parameters as per respective GPs.

4.1.8 Check the following parameters as per their respective GPs and record it in the In process Control Chart at

the start of operation and at random intervals not exceeding 2 hours.

Cleanliness of the bottles

Fill volume

Capping / Torqueing

Sealing / Leak test

4.1.9 The sample drawn for In process inspection shall be destroyed after performing the test.

4.1.10 In case the above parameters are not being met with, inform the Production Officer about the defect(s) noticed.

4.1.11 Production should start only after the defects have been rectified and certified by the Production Officer.

4.1.12 Recheck all the parameters and let Production continue in case the parameters are within the limit.

NOTE:- In case of any major defect or defects of recurring nature, immediately inform the Quality Assurance

Manager and ensure that the complete lot is quarantined.

4.2 Labeling & Packaging

4.2.1 On receipt of “Packaging Line clearance / Packaging Line Operation & Inspection record from the Production,

stating that the line and area is ready for Quality Assurance Inspection, inspect the following for cleanliness

and presence of any remnants of previous products / batch.

A, Turn table.

B, Labeling machine.

C, Packing belt and surroundings.

4.2.2 If the area is free from the previous product / batch, enter the same in Packaging Line clearance &

Packaging Line Operation & Inspection record and give the clearance.

4.2.3 Ensure that the details of packaging operation are indicated on the display board.

4.2.4 Ensure that the documents in BMR are duly completed upto the last operational stage.

4.2.5 Ensure that all the packaging components are on the line as per the packaging Order.

4.2.6 After the coding stereos are assembled and the coded Label is approved by production Officer, check the

coding of the stereo and ensure that coding details are as per the requirement of the product /pack / market with

respect to Batch No. , Mfg. Date , Exp. Date , M.R.P.etc. If the coding is correct, approve the same by signing on

the Label and attach in the Batch Manufacturing Record.

Note: Coding approval on Labels to be done for every day or whenever there is any change in the

stereos, operator / shift etc.

In case of off line coding ensure that all precoded packaging components are approved by production Officer and

the specimens are attached in the BMR. Quality Assurance Officer shall approve all the packaging components

and details prior to start of packaging operation.

4.2.7 Challenge the safety mechanisms fitted on machines and ensure their satisfactory working and record

the observation in Packaging line operation & inspection record.

4.2.8 Inspect the packs at the start of operation and at regular intervals (not exceeding 2 hours) as per

the sampling plan and record the observation in Packaging line operation and inspection record for the following.

a. Coding and printing details on Shippers ,Cartons & Labels.

b. Missing Label.

c. Crumpled / Slanted / Stained on labels

d. Inks lifting on Labels.

e. Empty Bottle.

f. Low fill / High fill Bottle.

g. Dented / Stained /Scratch marks on the bottles .

h. Scarting / Bridge breaking.

i Defective colures.

J Abnormal colour, odor & appearance.

4.2.9 In case any defect is observed inform immediately the Production Officer / Manager to rectify it. Record

the observations in the Packaging Line Operation and Inspection Record. Ensure that the defect has been rectified by the concerned Production personnel.

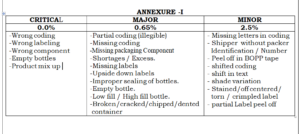

4.2.10 Classify the defects observed as per the guideline given in annexure-1.

4.2.11 In case any critical defect is observed the operation shall be immediately stop and the involved quantity

shall be quarantined. Operation shall be restarted only after taking corrective action.

4.2.12 In case of major and minor defects corrective action shall be immediately taken on the packaging line.

At the end of operation if the number of defective of one kind exceeds the acceptance number

Given in the sampling plan, the involved quantity shall be rejected and subjected for reinspection or necessary corrective action.

4.3 Ensure that the rejected packs are stored in containers with batch identity and rejection status label

of recoverable or non recoverable and send for further processing as per the Respective SOP.

4.4 Collect control & stability samples (Wherever required) of packed products. Record the details in Packaging

line Operation and Inspection Record and Control / Stability sample Register.

5.0 ABBREVIATIONS :

BMR = Batch manufacturing record.

MRP = Maximum retail price.

SOP = Standard Operating Procedure.

6.0 ANNEXURES :

ANNEXURE –1 : List of category of defects

Online Rejection in parenteral

Receipt of Batch from Production to Packing Department

sop for for Spillage Handling in parenteral area

sop for calibration of vessels with dipstick

sop for Cleaning of Bins and Containers

cip of mixing vessel and holding vessel

sop for Cleaning of Ampoule Filling and Sealing Machine

sop for Fogging in Sterile and Non Sterile Area

sop for for Filtration of Bulk Solution

sop for fumigation in production area

sop for post cleaning after media fill

sop for cip of mixing vessel mixing mobile vessel and holding vessel

sop for De-Bagging of Three Piece Vial Dropper Caps

sop for calibration and verification of check weigher

sop for Batch number and Manufacturing and Expiry Date Coding System

standard operating procedure machine history file

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for for charge hand over between the shifts

Performance requalification report of visual inspectors

sop for Cleaning and operation of ROPP caps inspection table

sop for usage and destruction of filter pad and cartridge filter

sop for cleaning and storage of transfer pipe

sop for Cleaning and operation of labeling machine

Cleaning and operation of the mono block filling and sealing machine

sop for Cleaning and operation of empty bottle inspection table

sop for Cleaning and operation of filter press

sop for cleaning and operation of liquid transfer pump and line

sop for cleaning and operation of storage vessels

sop for cleaning and operation of sugar syrup manufacturing vessel

sop for cleaning issuance and retrieval of accessories and change parts

sop for Cleaning and operation of visual inspection conveyor belt