Sop for issue of material

1. PURPOSE & SCOPE: To laydown the procedure for issue of materials.

2. RESPONSIBILITY

Store keeper

3. AUTHORITY

Store incharge

4. PROCEDURE

1. Any material whether raw or packing material are to be issued against requisition raised by the store indenting department.

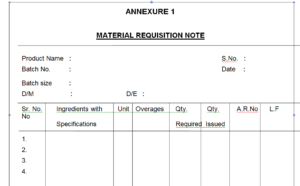

2. The material requisition is raised in the format given in Annexure 1.

3. The materials are issued on First in First out basis (FIFO) .

4. After receiving the requisition the store keeper takes all the required materials one by one in the dispensing room and

batch quantity is weighed or counted in presence of Manufacturing Chemist / Production Officer.

5. Incase of material of higher quantity as or over standard pack size is required the full pack or full pack and part are issued.

6. When the quantity required is very small they are weighed and issued in

double lined poly bags.

7. Mouth of the poly bag is tied by thread and a tag is attached as follows:

Name of the material : Quantity :

For Batch No. : Weighed By :

Checked By : Date :

8. After weighing the left over materials are brought back to stores and kept at their respective place / position.

9. The quantity issued is recorded and subtracted from the stock register.

10. Store keeper finally keeps all the materials on a trolley and gets the requisition slip received by the indenting department and then

allows the material to be taken from dispensing room.

11. A separate register is maintained in the dispensing room where the items are issued on daily basis.

Online Rejection in parenteral

Receipt of Batch from Production to Packing Department

sop for for Spillage Handling in parenteral area

sop for calibration of vessels with dipstick

sop for Cleaning of Bins and Containers

cip of mixing vessel and holding vessel

sop for Cleaning of Ampoule Filling and Sealing Machine

sop for Fogging in Sterile and Non Sterile Area

sop for for Filtration of Bulk Solution

sop for fumigation in production area

sop for post cleaning after media fill

sop for cip of mixing vessel mixing mobile vessel and holding vessel

sop for De-Bagging of Three Piece Vial Dropper Caps

sop for calibration and verification of check weigher

sop for Batch number and Manufacturing and Expiry Date Coding System

standard operating procedure machine history file

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for for charge hand over between the shifts

Performance requalification report of visual inspectors

sop for Cleaning and operation of ROPP caps inspection table

sop for usage and destruction of filter pad and cartridge filter

sop for cleaning and storage of transfer pipe

sop for Cleaning and operation of labeling machine

Cleaning and operation of the mono block filling and sealing machine

sop for Cleaning and operation of empty bottle inspection table

sop for Cleaning and operation of filter press

sop for cleaning and operation of liquid transfer pump and line

sop for cleaning and operation of storage vessels

sop for cleaning and operation of sugar syrup manufacturing vessel

sop for cleaning issuance and retrieval of accessories and change parts

sop for Cleaning and operation of visual inspection conveyor belt