sop for Preventive Maintenance of Equipments and Machineries

1.0 OBJECTIVE :

1.1 To lay down the procedure for Preventive Maintenance of Equipment’s & Machineries.

2.0. SCOPE :

2.1 This procedure is applicable to all Equipments ,Machineries & Utility at Pharma Dekho

3.0. RESPONSIBILITY :

3.1 Technician / Operator / Supervisor of EM Department shall be responsible to carry out the Preventive

Maintenance of Equipments & Machineries as per schedule and maintaining the record.

3.2.1 Officer / Dy. Manager Engineering Department shall be responsible to Check Preventive Maintenance of

Equipments & Machineries and to take corrective action if any deviation.

4.0. ACCOUNTABILITY :

4.1 Head Engineering Department shall be accountable for compliance of SOP

5.0. PROCEDURE :

5.1. EM department person shall prepare Annual Preventive Maintenance Plan in respect of Monthly / Bi-

Monthly / Quarterly / Half yearly / Yearly as per Annex-I and send it to Head -EM for signature and final approval by Head QA.

5.2. All Equipments , Machineries and Utility shall be included in Annual PM planner.

5.3. After the approval of Head – QA , Department Executive / Dy- Manager shall prepare Preventive

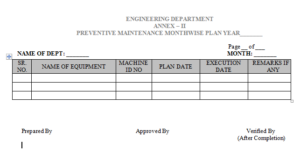

Maintenance Month-wise schedule as per Annex- II.

5.4. Indicate the scheduled and execution status in Yearly and Monthly Planner.

5.5. The list of equipments which are scheduled for preventive maintenance in a particular month shall be

informed to the head of the concerned department through Annex-II.

5.6. Preventive Maintenance of all equipment shall be performed during no operation condition of that

equipment on “Weekly off” or no production activity or in standby condition (Utility case).

5.7. Ensure that the PM shall be carried out within the “ Planned month”.

5.8. The Engineering activity shall be allocated to the technicians / engineering personnel with the relevant

Preventive maintenance checklist.

5.9. Follow below mentioned general procedure for Preventive maintenance of Equipment & Machineries :

5.9.1 The preventive maintenance activity should be recorded in the Check List.

5.9.2 Before preventive maintenance activity :

5.9.2.1 Ensure that main switch of equipment is off and electric supply cord ( if applicable ) is detached.

5.9.2.2 Affix a label of “UNDER MAINTENANCE” on Machine, Equipment or Utility.

5.9.3 During Preventive maintenance activity :

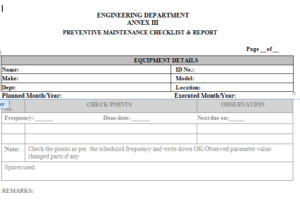

5.9.3.1 Attend the machines as per the planner and record the activity in checklist as per Annex-III.

5.9.3.2 If the preventive maintenance of equipment could not be carried out as per scheduled date, the same shall be

carried out on subsequent suitable date. However such machines shall be attended within the prescribed

time limits from the due date as per Point No. 5.7.

5.9.3.3 In case of any abnormal observation, the technician/ engineering personnel shall immediately report it to the

Engineering Officer and take corrective action as per the directives

5.9.3.4 Preventive maintenance shall include the replacement of any parts required over and above servicing so that

the machine keeps giving satisfactory performance in day-to-day operations.

5.9.3.5 On completion, report (Annex-III) shall be filled. Such records shall be signed by the

concerned department head along with the engineer concerned.

5.9.4 After completion preventive maintenance activity :

5.9.4.1 Connect electric supply of equipment.

5.9.4.2 Remove the label of UNDER PREVENTIVE MAINTENANCE from equipment.

5.9.4.3 Clean surrounding area of machine and collect all scrap/waste /used items.

5.9.4.4 Hand-over the machine to concern department head.

5.10 If additional jobs other than those scheduled as per checked list are done, (e.g.:Major change or replacement of

machine parts) which may have impact on the validated system, intimate QA Manager / Head to Asses the

impact. If QA decides that there is no direct or indirect relationship between the change and the final quality

of the product, product safety, product efficacy or the compliance and regulatory status, no further action is

necessary and record of the same to be mentioned in Annex-III whenever applicable .

5.11 If QA decides that there is an impact of the change on the final quality of the product, product safety,

product efficacy or the compliance and regulatory status then change control procedure shall be followed as

per SOP No.: 1QA-007

5.12 At the end of the year or whenever deemed necessary, all the PM activities shall be reviewed and analyzed, i.e. planned vs. actual for any Improvement and if required the PM frequency shall be modified after following proper change control.

5.13 For any addition or Deletion of Equipment & Machineries, following correction shall be in Annex-I

and Annex-IV :

5.13.1 For Deletion – Draw a line in same Equipment row and write “DELETED” in Annex-I

5.13.2 For Addition – Enter new Equipment & Machineries in Annex-IV for its Preventive maintenance.

5.14 Symbol used for P.M. Planner Schedule :

M- Monthly , B- Bi Monthly , Q – Quarterly , H- Half Yearly , Y – Yearly

5.15 If Equipment & Machineries falls under more than 1 category as per planned, than all previous

category check points shall also cover in the Higher category P.M. schedule. For example M,Q,H comes in same month ,than M,Q check points shall cover with H check points

6.0. ABBREVIATION :

| Sr. No. | Abbreviation used | Full form of abbreviation used |

| 1.0 | SOP | Standard Operating Procedure |

| 2.0 | EM | Engineering & Maintenance |

| 3.0 | QA | Quality Assurance |

| 4.0 | PM | Preventive Maintenance |

7.0 ATTACHMENTS (ANNEXES) :

Annex-I : Preventive Maintenance Annual Planner for the Year

Annex-II : Preventive Maintenance Month Wise Plan

Annex-III : Preventive Maintenance Checklist & Report

Annex-IV : New Equipment & Machineries Preventive Maintenance Annual Planner

8.0 REFERENCE :

In House

Annex-II : Preventive Maintenance Month Wise Plan

Annex-III : Preventive Maintenance Checklist and Report

Online Rejection in parenteral

Receipt of Batch from Production to Packing Department

sop for for Spillage Handling in parenteral area

sop for calibration of vessels with dipstick

sop for Cleaning of Bins and Containers

cip of mixing vessel and holding vessel

sop for Cleaning of Ampoule Filling and Sealing Machine

sop for Fogging in Sterile and Non Sterile Area

sop for for Filtration of Bulk Solution

sop for fumigation in production area

sop for post cleaning after media fill

sop for cip of mixing vessel mixing mobile vessel and holding vessel

sop for De-Bagging of Three Piece Vial Dropper Caps

sop for calibration and verification of check weigher

sop for Batch number and Manufacturing and Expiry Date Coding System

standard operating procedure machine history file

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for for charge hand over between the shifts

Performance requalification report of visual inspectors

sop for Cleaning and operation of ROPP caps inspection table

sop for usage and destruction of filter pad and cartridge filter

sop for cleaning and storage of transfer pipe

sop for Cleaning and operation of labeling machine

Cleaning and operation of the mono block filling and sealing machine

sop for Cleaning and operation of empty bottle inspection table

sop for Cleaning and operation of filter press

sop for cleaning and operation of liquid transfer pump and line

sop for cleaning and operation of storage vessels

sop for cleaning and operation of sugar syrup manufacturing vessel

sop for cleaning issuance and retrieval of accessories and change parts

sop for Cleaning and operation of visual inspection conveyor belt

sop for Cleaning and operation of spray gun and assemble

sop for Cleaning of Air Handling Unit Ducting

sop for Uninterrupted Power Supply UPS

sop for Operation of Chiller and Pumps

sop for Preventive Maintenance of Equipments and Machineries