standard operating procedure machine history file

1.0 PURPOSE

To define a procedure for maintaining history in case of any minor/major changes/modifications done in the critical Machines.

2.0 SCOPE

2.1 This procedure applies to all critical machine used for various stages of dispensing, manufacturing and packing of formulations and machines used for supply of utility services for production activities

3.0 Abbreviations

3.0.1 No. : Number

3.2.1 EHS : Environment, Health and Safety

3.2.2 SOP : Standard Operating Procedures

4.0 RESPONSIBILITY:

4.1 User Department:

4.1.1 To fill and maintain the Machine history file.

4.2 Quality Assurance Head:

4.2.1 To ensure implementation of the defined procedure.

4.3 Plant Head:

4.3.1 To ensure implementation of the defined procedure.

5.0 Distribution:

I. Quality Assurance

II. Quality Control

III. Production

IV. Ware house

V. Engineering

6.0 PROCEDURE:

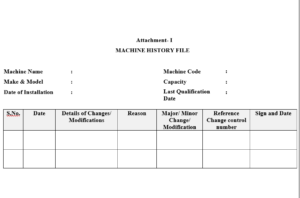

6.1 After installation and subsequent handover of the machine for regular use, the ‘Machine History file’ shall be maintained with details of any minor/major changes/modifications with reason as per Attachment-I.

6.2 The changes made shall be recorded whenever changes or modifications are carried out.

6.3 On completion of minor/major changes/modifications the machine shall be cleaned as per respective machine cleaning (product changeover cleaning if applicable) SOP.

6.4 Machine shall be certified by Production, Engineering, EHS and Quality Assurance department for proper setting and operation to get zero defect before use of machine for Production activities.

6.5 After rectification of all critical and major breakdowns, the machine shall be re-qualified as per SOP “Qualification of Equipment”.

7.0 References

7.0.1 SOP : Qualification of Equipment

8.1 Attachments

8.1.1 Attachment- I: Machine History file

Online Rejection in parenteral

Receipt of Batch from Production to Packing Department

sop for for Spillage Handling in parenteral area

sop for calibration of vessels with dipstick

sop for Cleaning of Bins and Containers

cip of mixing vessel and holding vessel

sop for Cleaning of Ampoule Filling and Sealing Machine

sop for Fogging in Sterile and Non Sterile Area

sop for for Filtration of Bulk Solution

sop for fumigation in production area

sop for post cleaning after media fill

sop for cip of mixing vessel mixing mobile vessel and holding vessel

sop for De-Bagging of Three Piece Vial Dropper Caps

sop for calibration and verification of check weigher

sop for Batch number and Manufacturing and Expiry Date Coding System

standard operating procedure machine history file

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for for charge hand over between the shifts

Performance requalification report of visual inspectors

sop for Cleaning and operation of ROPP caps inspection table

sop for usage and destruction of filter pad and cartridge filter

sop for cleaning and storage of transfer pipe

sop for Cleaning and operation of labeling machine

Cleaning and operation of the mono block filling and sealing machine

sop for Cleaning and operation of empty bottle inspection table

sop for Cleaning and operation of filter press

sop for cleaning and operation of liquid transfer pump and line

sop for cleaning and operation of storage vessels

sop for cleaning and operation of sugar syrup manufacturing vessel

sop for cleaning issuance and retrieval of accessories and change parts

sop for Cleaning and operation of visual inspection conveyor belt