sop for Fogging in Aseptic and Non Aseptic Area

1.0 OBJECTIVE:

1.1 To lay down a procedure for Fogging in Aseptic and Non Aseptic Area.

2.0 SCOPE:

2.1 This SOP is applicable for Fogging in Aseptic and Non Aseptic Area in Injection Parenteral

3.0 RESPONSIBILITY:

3.1 Officer / Executive Production

4.0 ACCOUNTABILITY:

4.1 Head Production

5.0 PROCEDURE:

5.1 PROCEDURE:

5.1.1 Operator/Staff/Helper shall be wear goggles during fogging and leave the area after start the fogger.

5.1.2 Area AHU should be OFF before 5 min of fogging and should be start after 30 min of fogging.

5.2 Check & ensure that the area intended for fogging is completely closed.

5.3 Silvicide shall be used as Fogging Agent.

5.4 20% Solution of Silvicide in WFI shall be used as Fogging Solution. (For 1000 cu. ft. Area to be fogged

with Fogger – 200 ml of Silvicide in 800 ml WFI to be used).

5.5 Fogging with 20% Silvicide Solution shall be performed in the particular Area.

5.6 After Fogging, leave the Area in Static Condition up to one hour for complete sanitization.

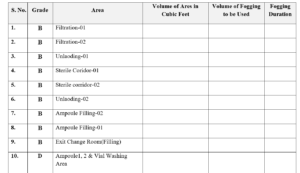

5.7 Area should be fogged with defined time which is mention in Annexure-III, Titled “Fogging Solution Usage Record”.

5.8 Clean the Area and Equipment before starting of any activity with scheduled Disinfectant Solution for the day.

5.9 Record the Fogging details in Annexure-I, Titled “Fogging Record of Aseptic Area and Annexure-II, Titled “Fogging Record of Manufacturing/Washing & Sterilization/Unit preaparation

5.10 Frequency:

5.10.1 Daily and after Operation

Fogging frequency may be increased on the basis of Environmental Monitoring Report of the said Area.

Shut Down

Microbial Count (Beyond Limit)

6.0 ABBREVIATIONS:

| Sr. No. | Abbreviation used | Full form of Abbreviation used |

| 1. | SOP | Standard Operation Procedure |

| 2. | Ltd. | Limited |

| 3. | WFI | Water for Injection |

| 4. | Sr. No. | Serial Number |

| 5. | QA | Quality Assurance |

| 6. | QC | Quality Control |

| 7. | Cu. Ft. | Cubic feet |

7.0 ATTACHMENTS (ANNEXES) :

Annexes-I : Fogging Record

Annexes-II : Fogging Record of Manufacturing/Washing and Sterilization/Unit preaparation.

Annexes-III : Fogging Solution Usage Record.

8.0 REFERENCES:

| S. No. | Reference Title |

| 1. | In-House |

Annexes-I

FOGGING RECORD OF ASEPTIC AREA

Department: Production –Fogging Agent:

Date:

Frequency: Daily and after operation

|

Area |

Time |

Done By |

Checked By | |

| From | To | |||

| Ampoule Filling-III

|

||||

| Ampoule Filling-II

|

||||

| Ampoule Filling –I

|

||||

| Buffer Zone | ||||

| Unloading room-II | ||||

| Unloading room-I | ||||

| Filtration-I | ||||

| Filtration-II | ||||

| Sterile corridor | ||||

| Air Lock -IV | ||||

| Air Lock-III | ||||

| Air Lock -II | ||||

| Air Lock –V | ||||

| Air Lock -I | ||||

Annexes-II

FOGGING RECORD OF MANUFACTURING/AMPOULE WASHING/UNIT PREPARATION

Department: Production Area:

Month: Fogging Agent:

Year: – Frequency: Weekly ±1Day

| Date | Area | Fogging Time | Done By

Sign & Date |

Checked By

Sign & Date |

Remarks | |

| From | To | |||||

Annexes-III : Fogging Solution Usage Record

Online Rejection in parenteral

Receipt of Batch from Production to Packing Department

sop for for Spillage Handling in parenteral area

sop for calibration of vessels with dipstick

sop for Cleaning of Bins and Containers

cip of mixing vessel and holding vessel

sop for Cleaning of Ampoule Filling and Sealing Machine

sop for Fogging in Sterile and Non Sterile Area

sop for for Filtration of Bulk Solution

sop for fumigation in production area

sop for post cleaning after media fill

sop for cip of mixing vessel mixing mobile vessel and holding vessel

sop for De-Bagging of Three Piece Vial Dropper Caps

sop for calibration and verification of check weigher

sop for Batch number and Manufacturing and Expiry Date Coding System

standard operating procedure machine history file

sop for operation and cleaning of Hand coder

sop for Cleaning and Handling and Silicone Tubes

sop on operation and cleaning of coating pan

sop for Operation of cleaning of pipe lines

sop for operation of capsule loading machine semi automatic

sop for Machine operation capsule inspection and polishing machine

Sop batch demarcation and batch coding

sop for monitoring of reprocessing of products

sop for in-process control on liquids orals

sop for in process controls on tablets capsules packaging line

sop for Issuance retrieval and destruction of BMR and analytical records

sop for in process controls during granulation compression coating inspection

sop for Cleaning of Blister packing machine

sop for for charge hand over between the shifts

Performance requalification report of visual inspectors

sop for Cleaning and operation of ROPP caps inspection table

sop for usage and destruction of filter pad and cartridge filter

sop for cleaning and storage of transfer pipe

sop for Cleaning and operation of labeling machine

Cleaning and operation of the mono block filling and sealing machine

sop for Cleaning and operation of empty bottle inspection table

sop for Cleaning and operation of filter press

sop for cleaning and operation of liquid transfer pump and line

sop for cleaning and operation of storage vessels

sop for cleaning and operation of sugar syrup manufacturing vessel

sop for cleaning issuance and retrieval of accessories and change parts

sop for Cleaning and operation of visual inspection conveyor belt

sop for Cleaning and operation of spray gun and assemble